Assuming you’r already in inch mode:

G10L20P1Z1.000

All great suggestions here. Mine:

- Allow the user to change the default 5mm ‘safety’ Z Axis offset. For those of us that zero to the wasteboard, 5mm isn’t enough.

- Multiple user determined preset positions (in addition to, or replacement of, default rapid positions).

- A timer.

- Warning if a cut goes outside of the machine boundaries.

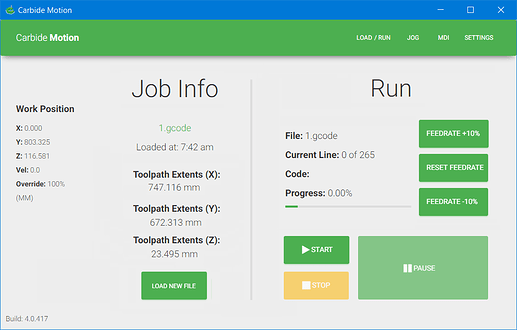

- Merge the Load and Run tabs into one.

- The ability to probe with a different tool diameter (I almost exclusively cut with a 3/16" mill).

- Display a loaded program’s Toolpath Extents in the units that the user has selected - if using inches, display in inches; if using millimeters, display in millimeters. Or, display both units.

- On the Run tab, make the Pause button much bigger & an easier target.

And for what it’s worth, I’d happily pay to have these things. Carbide Motion Pro.

I second this (and 3rd, 4th, 5th it):

the carriage should move full up so you can get at the tool, you change the tool out, then there’s a re-zero’ing “special page”, where you can move around in X,Y, set your zero, then hit … wait for it… “DONE”. and then, unlike some of the moves I’ve seen where you travel with all 3 axes active, at “done”, carriage should go full up, travel over to X,Y zero, then re-start. That way you can re-zero someplace without worrying about running into some middle-of-the-piece hold-down tooling.

biggie #2:

The re-home thing is beyond annoying. C’mon! Or, tell us why it has to happen.

#3:

a countdown that’s accurate, instead of a percentage of lines accomplished. I’m thinking it wouldn’t be too bad to calculate time of each step based on motion speed and give us a more accurate time-to-completion?

that being said, #3 is a nice-to-have - the first 2 are the big ones that jump out.

I’ll see if I can come up with some more creative improvements, instead of just venting with my annoyances!

thanks - Chris

Another vote for being able to adjust Z-axis zero mid-job.

Is version 416 is ok for the HDZ

No, you’ll need CM417 which is in beta:

Remove the stupid Done button. IF the menu shows something, it is logical that you can select it, without the need to press Done in a window that is not a dialog box.

I would also like a Zeroing that is just the zero point of the machine. Most of the stuff I make uses the physical zero as the start point.

Make it refuse to go to coordinates outside of the boundary.

Also. Please remember if the current tool already has been probed (Nomad). Every time I run, it measures the tool and the next step is (you guessed it) click ok to measure the tool. I do use Fusion360 for the G-code, and it does post a tool change at start.

And yes, a preview would help me see when I fucked up the axis. Come on, even free 3D printer slicers come with preview!.

Btw; I just invested in a touch screen. Please don’t make the new version worse on touch screens.

I’m new to CC but a countdown timer would be a great help.

I want to be able to zero with my probe XYZ with my 6mm, and not the “default” 1/8" you provided with the machine.

Most user requests could be resolved by simply implementing some kind of plugin framework. Rather than open-source the code, add endpoints that plugins could tie into. For example, events when something is about to happen, then after it happens.

If we had that we could code most user requests, and start implementing functional libraries. I know that’s a big ask, but we could take care of most of the other asks as a community.

I’d like more control over the tool library, being able to change the labels and maybe allocate feeds and speeds to a particular tool instead of having to do it every time I select a tool.

Also, I work in metric and CM seems to be a bit strange the way it gets back and forth between imperial and metric. I’d like to be able to lock it in to metric permanently. Even though I select metric, imperial seems to turn up in the tool library.

I get the impression CM is really working in imperial and is constantly converting back and forth with resulting rounding errors.

Of course, I could be doing it completely wrong.

Yes many proprietary software, like Excel has the ability to create macros and plugins but it remains a closed box. When you look at the competition, Vectric (VCarve, Aspire) lets users create gadgets with a free SDK and Easel has the ability to create plug-ins too while CC and CM remain a close box with no possible improvements until the code is upgraded which is not something done regularly.

Add to this - when a program finishes, CM flips back to the Info/Load tab. It’s nice if you’re changing programs, but I run the same program multiple times, so I have to go back to the Run tab to start my program again. Combining these tabs into one works for either workflow. Something like below?

Interestingly, CC an CM all work exclusively in metric internally.

Indeed, on a few occasions when working in imperial units I have noticed rounding errors as a result of the conversion. These are, of course, very small and insignificant discrepancies… and only become obvious when rendering the simulation in CC. For example sometimes a render of a cutout toolpath doesn’t quite make it through the entire stock thickness… leaving an onion skin in the rendering…

I like your rendering but I would add the est time for the job on the load side and a countdown (time remaining) at the top of the run side.

Now can you do the merging of the Jog, rapid position, probe and zero screen into one too?

A timer that displays the run time from start to finish. A level above would be to keep a history sheet that shows the name of the file, run time, feeds and speeds such as in the Rayjet Commander printer driver for Troteck Rayjet lasers.

Also, another bid for removing the requirement to hit DONE on the jog page. From all of the other pages you can select one of the tabs directly.

It would be great to be able to pause, jog and then resume. For the times the job moves part way and you need to fix and resume …

From what I see so far, CNCJS meets 90% of the requests/suggestions made in this thread

Some sort of rotary axis. I know this version of GBRL doesn’t support a 4th axis but I’ve seen a video of someone basically swapping the Y axis to turn the rotary tool.

And like with laser cutters they have an “outline” button that moves the tool on the outside boundry of the job in question.

Maybe there’s a simple work-around that I don’t know, but I can’t use a J-tech laser gcode file, because CC always pauses after “Laser On” for the spindle to spin up - which causes a big fat laser dot. An option to not pause for the spindle would be great. If there’s a GCode command to achieve the same, please let me know !