@erict You need to enable GRBL’s Laser Mode ($32 = 1)

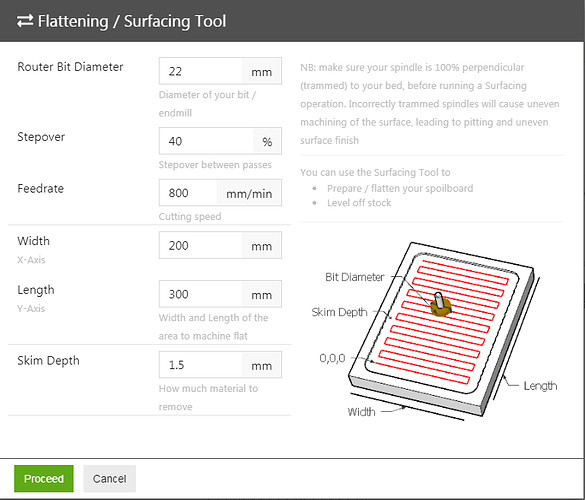

How about a workpiece / wasteboard surfacing “widget”?

Like this one:

Source

And a proper console for sending/receiving gcode and/or grbl commands.

Yes! And if we can do that, what about some simple conversational tools like square & round pocket and profile widgets? Where the user just punches in required dimensions, zeroes as required and hits go

I know it blurs the line between CC and CM but they would be awesome in the ‘pro’ version of CM

I vote for numbers 2, 3, and 4 here. Automatic HOME, multiple storable easily added HOME positions, and metric bit probing. These features would smooth workflow and eliminate potential errors. We’re doing a lot of two-sided machining and being able to set zero positions quickly would be a real timesaver. Love the multiple jig idea, as we’re doing small precise parts.

A Linux version would be nice.

A remote headless version that can run on a Linux SBC (like a Raspberry Pi) and controlled over the network from another (Linux) computer would be great.

There was a Linux version a while back, but it has been discontinued. To my mind, it doesn’t really make sense, since most folks running Linux want an all opensource toolchain.

A remote/headless version was actually announced as a product in development a few years ago:

https://carbide3d.com/blog/2017/feb-2017-update/

(scroll down to the bottom to see “Carbide Connect”)

While I prefer my softwares free (as in speech), it do make sense for me to have the option to use non-free software on Linux. When a non-free software clearly offers improvements over what’s is available as FOSS softwarse, many users don’t hesitate to pay and use them. In the software development world, the whole JetBrains software suite (IntelliJ, WebStorm, etc.) is available as closed source and paid for softwares on Linux.

I’ve no idea if Carbide Motion has any value because I wouldn’t go through the pain of running a Windows VM to try it when I’ve CNCjs perfectly working on a Raspberry Pi. Not making it available to Linux is a sure way to keep me not using it.

@pbuyle

I agree with you… I too run a headless raspberry pi with CNCJs. The nice thing about this is that I can control my Shapeoko from anywhere on any device with a browser. Usually a chrome book, sometimes my iPad and very rarely my android phone. It all works well together and cheaply.

As it happens I have just spent TWO whole days updating a windows 10 laptop for another project… which reminds me how totally overblown windows 10 is - if all you need to do is control a machine like a Shapeoko in your workshop! and expensive!

However, it is very likely that Carbide3D develops Carbide Motion further to give good extra and unique functionality that may make it desirable to use Carbide Motion… so in both yours and my workflow I would very much like to have a web browser controlled Linux version of Carbide Motion running on my headless pi! I suspect that there are many other headless raspberry pi Shapeoko users out there in the same boat!

Rather than a Raspberry Pi you can use an Intel Compute Stick running Windows 10.

The intel compute stick is expensive… especially once you buy and install windows 10 32 bit to go on it… $140 vs $40 for a pi. … to just run Carbide Motion? And you have to plug it into tv etc to make work… don’t think it can be run head less…

Should be able to set it up so that it boots into Windows and auto-runs Carbide Motion, then just connect to CM using the tablet interface on port 8080.

Use Remote Desktop to connect and do maintenance — I guess you could set it up so it uses Drop Box to have access to G-Code.

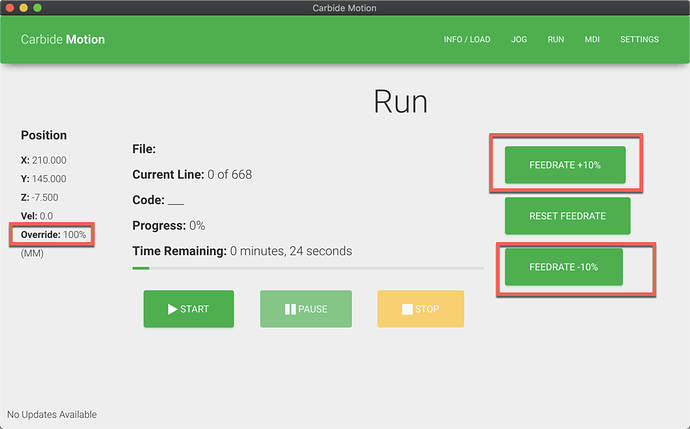

RickT is right, kill the done button. I’d also like to see a change to the ±10 feed rate change option. I’d like to know how much above or below 100% I am currently running.

My bad. I never noticed that before (new user, sorry)  Although now that you mention it, I wonder how much work it would be to move that particular bit if information either to the button itself, or maybe above or below it?

Although now that you mention it, I wonder how much work it would be to move that particular bit if information either to the button itself, or maybe above or below it?

I think a good reference is CNCJS you can visualize everything during your print and you can see your 3d model

I’ve been plenty happy with Carbide Motion for my use cases.

I will echo the request to stop and re-zero the Z axis after tool changes so you don’t have to split your G-code and run different jobs.

Also, port 8080 is used for a lot of things. I can’t run Carbide Motion (v7) and MeshCAM at the same time, because they both use that port… It’d be nice to have some options here, either for the user to specify a different port, or for CM to use a different port by default.

These two requests play together, as I need to export multiple jobs from MeshCAM, but don’t want to shut it down while I’m running CM. This would be a little less of a problem if I could do full tool changes and re-zero Z from one Gcode file.

Thanks to Rob and the team for making this software available to us. Keep up the great work.

Auto Leveling

I use bCNC and Chilipeppr for the small engraving projects. I can not keep my projects to 0.01 inch variation in flatness (probably operator error). Quarter inch, 6 to 7mm, high text even with a 45 degree V bit, really demands that level of flatness.

I have recently been engraving on the inside of bowls I have turned on a lathe. Auto Leveling lets me engrave on the bowl’s curved bottom.

@robgrz: So, I’m wondering if Carbide will be publishing a list of what y’all plan to implement from this list. After all the votes are in, which change requests have made the cut?

Autoleveling - would make engraving and pcb’s easier

Autocalibration - could be done using the probe as a fixed, known size standard to calibrate steps.

Usally I don’t paricipate in this kind of discussions, but since I really, really, really, really want keyboard comands for everything in motion I couldn’t resist…