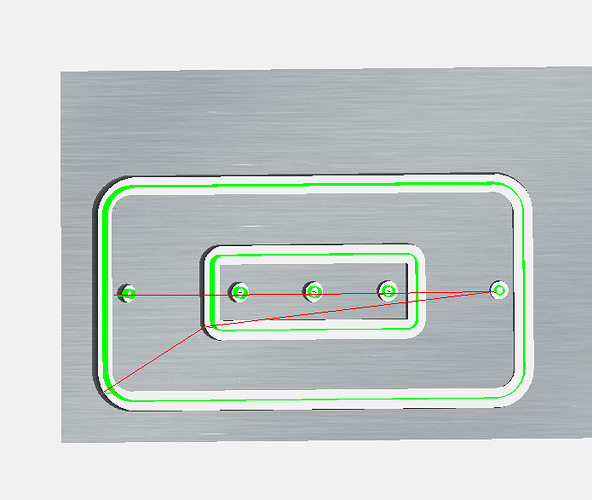

Is there really not a way to change the starting point of a tool path? This is the design I’m trying to cut out - the small rectangle is just a .5mm deep carving as an outline. The larger rectangle with the fillet corners is what I’m trying to cut out, but the tool path wants to start in the lower left corner which happens to be in the middle of the fillet instead of on one of the straight edges. So that lower left corner ends up a bit off compared to the other 3 corners. It’s a it frustrating that I can’t seem to find a work around for the design so that the final cut is somewhat accurate. Thoughts?

It is better to address why the machine isn’t cutting as expected.

If the machine is mechanically sound, then the solution is to address this in the toolpaths — offset things and leave a roughing clearance greater than the defect you are seeing, and offset to the outside by endmill diameter plus 10% and cut as a pocket down to tab height or the penultimate pass.

Hi William,

I was able to cut out several 7" letters in a Star Wars font earlier in the day, each as a separate file, and all turned out perfectly fine so the machine is mechanically sound (but I am still fairly new to this so who knows).

When cutting out the piece I have it set up as a contour toolpath with the offset as outside/right. Just making sure I understand what you’re suggesting - create a larger rectangle (bit diameter + 10%) and cut out as a pocket cut?

Would adjusting stepover settings help this at all, or is that not a significant enough to make a difference?

Thanks for your input!

Stepover mostly affects the quality of the bottom of the pocket. It shouldn’t be so small that the machine struggles to remove material.

See:

and/or

This topic was automatically closed after 30 days. New replies are no longer allowed.