At least with wood, climb milling would seem less likely to cause tear-out because thinner (rather than thicker) cuts occur when the cutter exits the workpiece. The thicker cuts occur as the cutter enters the workpiece, so the cutter would be less likely to rub on (and heat up) the workpiece before “taking a bite” of it. Climb milling chips are propelled behind the cutter’s advance so they’re easier to clear and less likely to interfere with the advancing cut and generate additional heat.

Isn’t the first pass of a pocket a full cutter width cut (i.e. both a climb and conventional cut)?

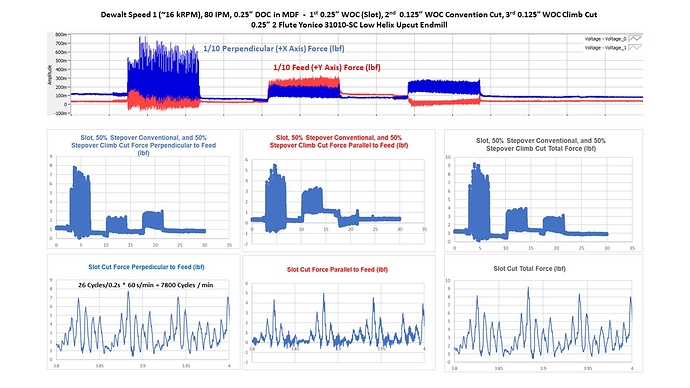

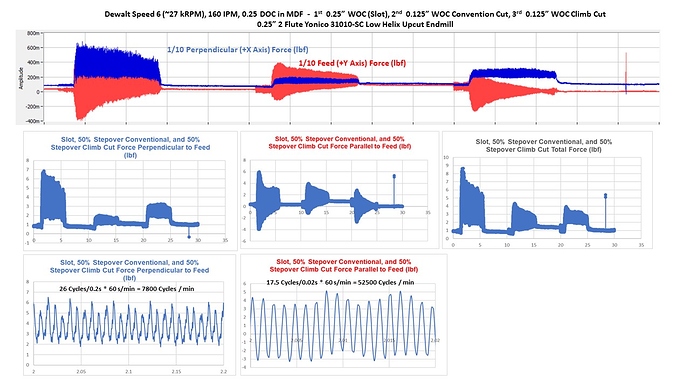

My experience suggests that there isn’t much difference in cutting power/force requirements for climb and convectional milling. The force measurement results shown below suggest that climb milling required only slightly less force (and machine deflection) than conventional. Comparing cutting current draw (thus cutting power and force) with your VFD should enable you to easily compare both approaches.