It’s been 3 months since the earlier post of mine in this thread where I said I would get one of those on Amazon:

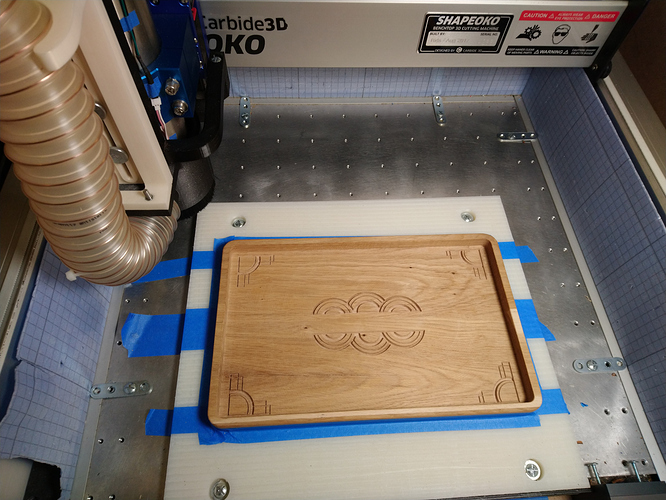

The opportunity to test it surfaced a few days ago when my wife told me that this wooden tray I had cut for her two years ago was not fancy enough and could use some improvement:

So I v-carved it Art Deco style,

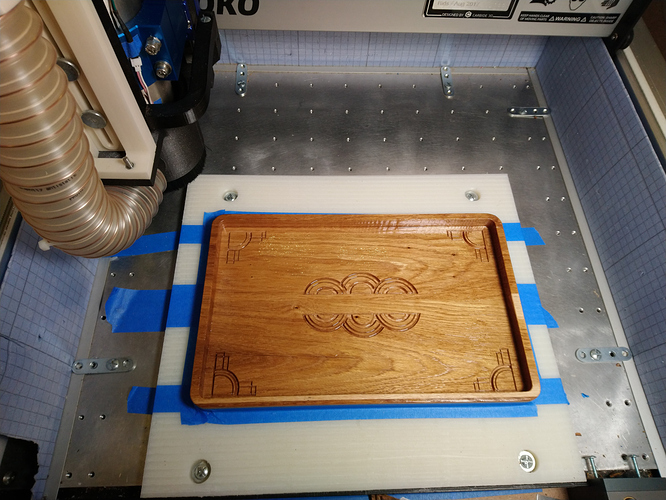

used a coat of clear epoxy to seal the wood,

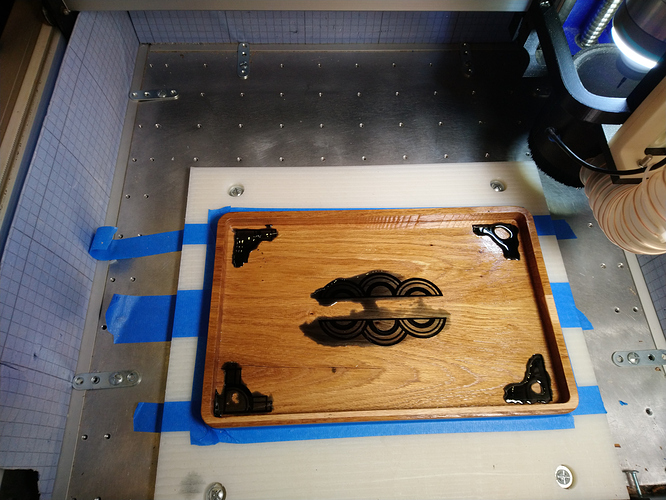

poured black epoxy “Julien style” (messy),

and then surfaced it with the Shapeoko, which left subtle tools marks (see the vertical stripes on the left and right sides? Yeah I mess with my machine so often that I’m in an endless “I need to re-tram it soon” mode))

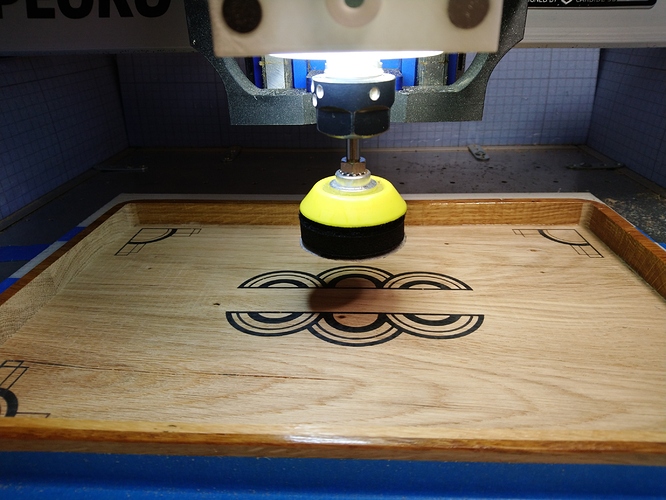

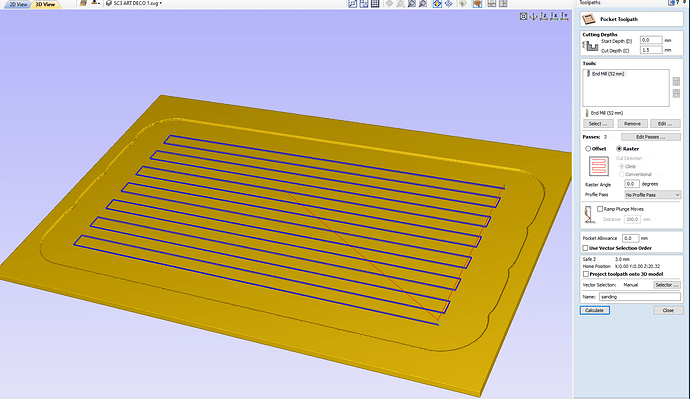

And since I hate sanding (with a passion), I figured I would try running a pass with a 180 grit disc:

And that’s where having a VFD and water-cooled spindle is an enabler for silly experiments like this one, I was able to set my RPMs very low (I chose 1000 RPM, arbitrarily, could have been less), because it would of course not be safe to spin that sanding head very fast.

I used a basic raster pocket toolpath, programmed for three passes of 0.5mm (which does not really mean much because the pad compresses, so depth of cut just translates to more or less pressure on the pad)

And inefficient as it may be to use a CNC for this (manual sanding would have been faster), I enjoyed not being the one doing the sanding A LOT:

Toolmarks all gone, but of course in the process I then learned the (obvious) lesson that the pad does not really do much sanding on its edge, and I can’t make the toolpath go too close to the walls, so I ended up with a good 10mm area around the walls and in the corners that will need manually sanding.

After the first pass, changing the disc to the next finer grit is very quick and I just reran the same toolpath repeatedly.

I’ll keep this option in mind for cases where I have large areas to sand on a top surface / with no obstacles, if only because I get to do something else nearby while the machine is working for me on sanding, which I call a minor victory.