I’ve had it where the data wasn’t updating down in window with spindle speed, spindle on/off, etc. Luckily I haven’t got my new spindle in and was still running off the Carbide Router. Hopefully it was still getting the commands in the gcode and just not updating the window.

Oh I haven’t even looked at my spindle info! I’m running the whole thing natively on my mac, so it’s not a disconnect error but that makes me wonder what will happen if my mac sleeps…

Yes. I have not personally seen it for a while, though.

Assuming you guys are using 20 or 21? That’s disappointing. Get as much info as you can and add to the issue’s thread.

Updated what I could.

I have seen it where the display no longer updates - elapsed time, time remaining, cut preview etc, all stop updating yet the cut continued fat, dumb and happy. If I recall it was after the laptop had gone to sleep for a second. I have since updated my power settings so it doesn’t sleep so I haven’t seen the issue again

OK all you CNCJS guys, this is a long drawn out intro video for CNCJS. There is a lot of extra steps here. I plan on doing another one later after my limit switch comes in to make it easier to understand. You guys have any suggestions to add or subtract from the next one? Really trying to help new guys get into the program without the fear of the unknown. (like I did)

That issue is my exact problem, I added myself to to the list. Thanks as always!

@ogbulldog That would have been incredibly helpful when I went to set up a couple weeks ago. There are a lot of newcomers to CNCjs that could benefit from this.

I’ve been working diligently in CNCjs to produce ground dowels from end mills. I’ve hit a snag, I’m attempting to load a .nc file that will likely crash into all of my workholding, and it wont load. All I get is the spinning loading wheel of death. Is there a flie size limit on js like there is on CM ?

While I’m posting I’d like to give a HUGE shout out to @neilferreri for his macros I’ve done some tweaking to get the “flavor” right for my XYZ probe, and you sir have saved me hours of work!

I get the occasional spin but if I refresh the browser it shows it’s loaded

Ahh good call, I’m in the Electron app, so I have no browser refresh. I’ll look to see what the equivalent is thanks for the tip!

EDIT: @wb9tpg Good call, that fixed it. If anyone runs across the same issue then go to View > Reload. or (Command +R) if you are on a mac.

OG, That was PERFECT! Thanks so much for making this video. I do have (for now) a couple of questions. Do you know how to set soft limits and is there a “Rapid Position” macro

I did make a Macro for the rapid positions. It’s pretty easy. I’ll post it here when I get home today. As far as the soft limits, as long as your gcode is correct and you home the machine, that shouldn’t be an issue. You can set them, but @neilferreri didn’t you say the Shapeoko did not like the hard/soft limits on CNCJS?

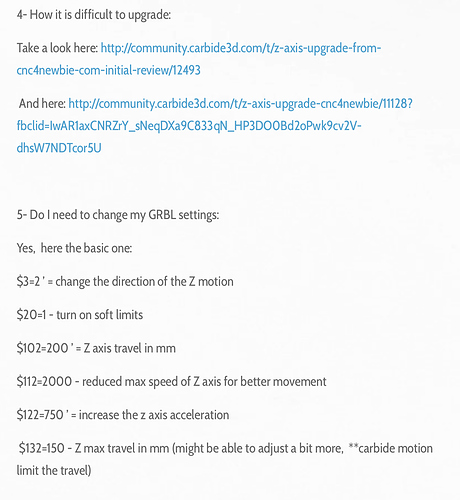

Make sure $130, $131, & $132 are accurate, and set $20 =1.

No issues with soft limits, but hard limits can be triggered by EMI (which is GUI independent).

G53 G0 X___Y___

Where the blanks are filled in with the desired MACHINE position (negative numbers in most use cases).

It takes a couple clicks to run a macro, sometimes faster to just type in the console for simple commands like that.

Thanks guys! You’re right, Shapeoko doesn’t like soft limits as it sets CNCJS in an alarm mode that needs resetting were as Carbide just wouldn’t allow you to crash but would continue

Rapid position it turns out isn’t as needed using CNCJS as you can just dial up the travel speed manually

New issue:

I ran the initial bit setter and it probed well and shot off to zero, yay, did tool path one, stopped and told me to change the tool. I ran Tool change macro and it probed great again, but then it raised the Z plate beyond it’s travel limit and crashed… Whaaaat?

I am using the new Z plate from CNC4NEWBIES

Does that Z plate have a different mm/turn? Not sure the Z steps on that one.

Both macros (initial and new) use the same Z heights. In your initial tool macro, what did you change %global.state.PROBE_Z_LOCATION to?

I don’t know that but will find out. Also, being as I’m such a newbie, just discovered the “machine profiles” and hoped that would help, but no. The only reason it bothers me is I can accidentally crash my machine when manually moving it. Also, after I have homed it, I then can manually move past the limit switches and crash it again. I guess I just became super comfortable with Carbide Motion.

As for Neil’s question, the problem is me. I forgot that I set my Z zero too high to allow me to do a dummy cut. Setting a realistic Z height seemed to fix the problem.

Do you know if when running normal operations and tool change etc.if a “spindle stop and run” command is programmed in already or am I going to have to add it.

I really want to thank ogbulldog for the video he made that allowed me to use CNCJS software. If it wasn’t for that video I would have just not bothered. Also, and obviously neilferreri for everything