Every year, we do a big Halloween display and each year we build props based on a new theme. This year was Alice’s Nightmare in Wonderland. One project was to build a “Rabbit Hole”. After ruling out digging a big hole in the front yard, we came up with the idea of trying to combine the hole with the spinning falling effect of falling down the rabbit hole. To do this, we decided on a hypnotic spinner that would be cut on the CNC using epoxy pours for the black and white of the pattern.

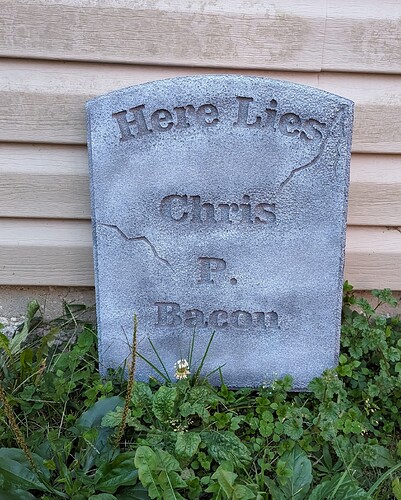

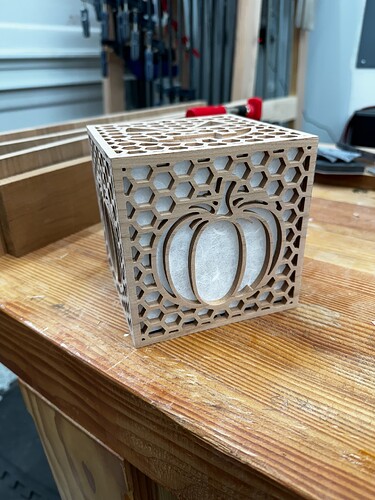

Here’s the finished product:

and a short video of it in action:

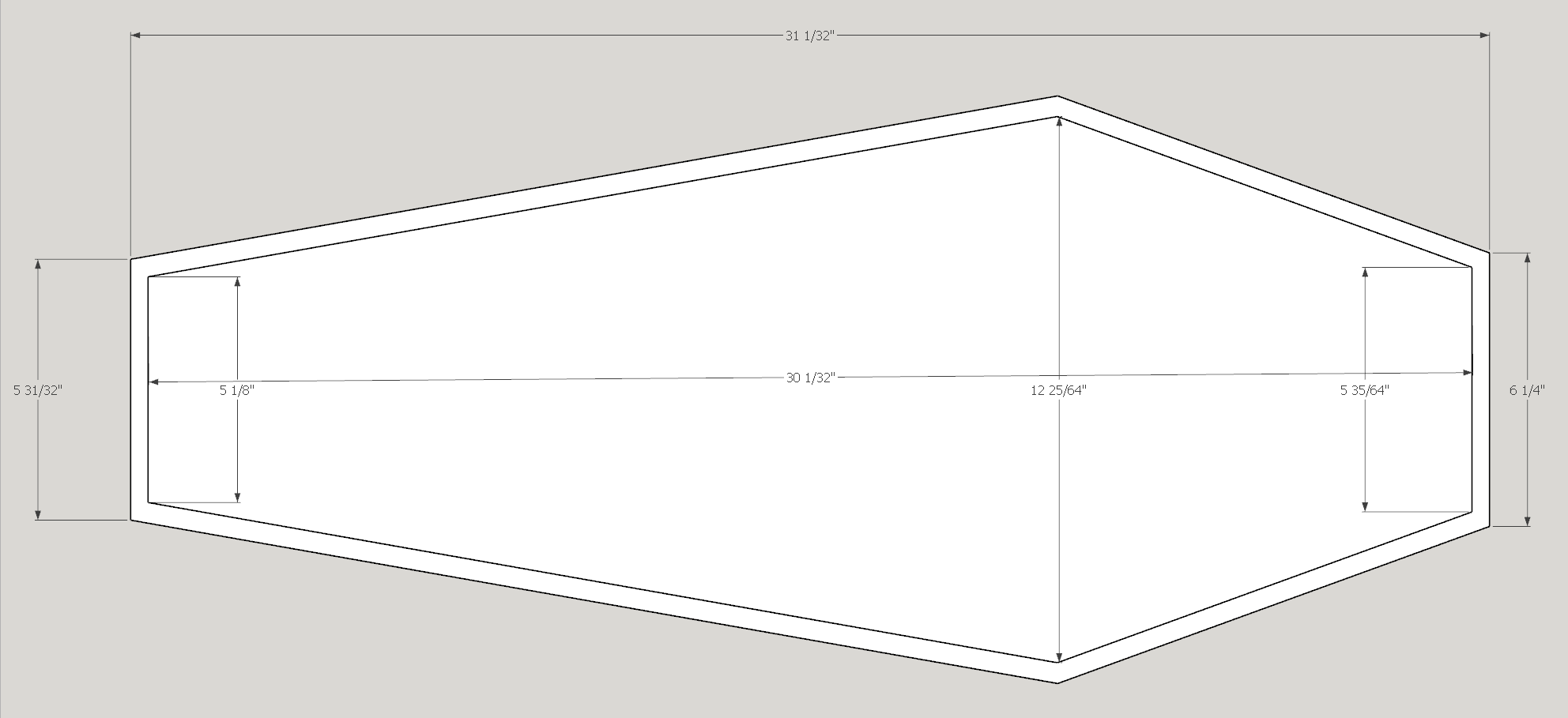

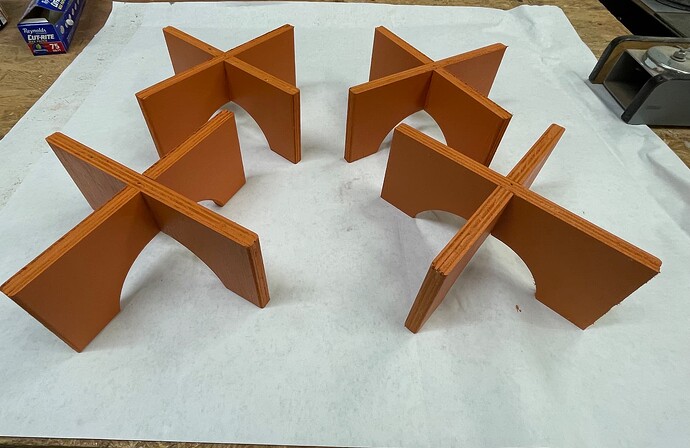

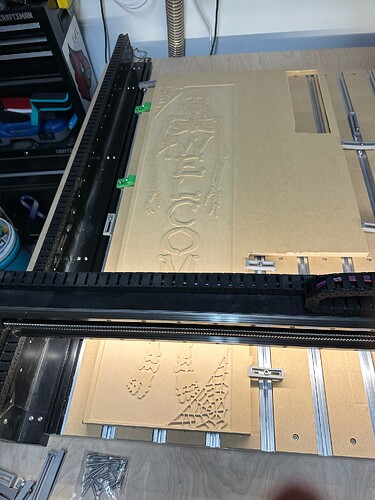

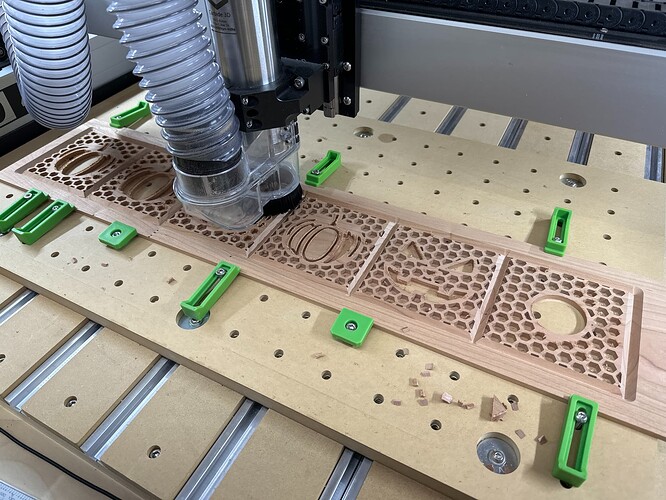

The spinner itself is 30" in diameter and cut on my Shapeoko 4 Pro using 2 tiles. It is cut out of a piece of PVC panel and the entire top surface is epoxy. It is mounted underneath to a motor. The motor assembly is built from aluminum extrusion and 3d printed parts.

I use CNCjs and a 3d touch probe purchased from amazon for my probing. This lets me very accurately (and easily) find the center of a hole. The design and machining was all done in Fusion 360 which let’s me use a hole center as the zero point for a job.

The series of jobs that I ran to get to the final product and how I set the zero for each part:

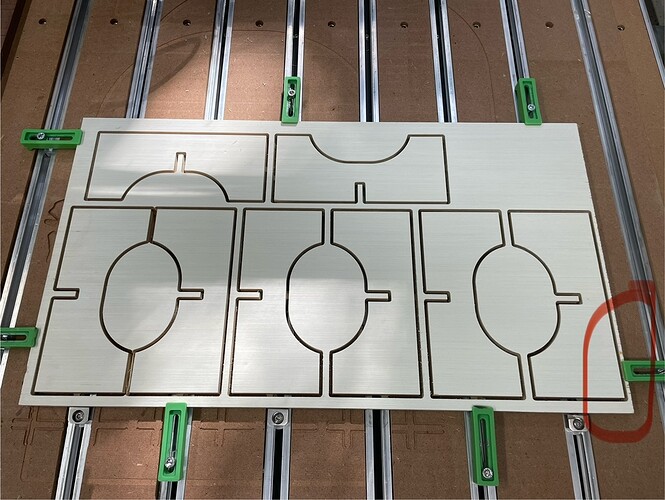

- Cut the underside to cut and tap mounting holes for the motor hub and drill a through hole.

- Flip the project and use the center of the through hole as my zero point, carve a new hole for setting the zero point and carve out of an overflow area to contain any excess epoxy I poured.

I used a second hole for the zero point because I stupidly setup the first job so that it was flipped side to side for the remaining jobs which meant that the first hole was cut 30"+ to the left side of the machine from where I was referencing it. I wanted to use a hole closer to where I was probing it to mitigate any error that 30"+ distance could have introduced. I’m sure it wouldn’t have mattered but I erred on the side of paranoia rather than make a mistake.

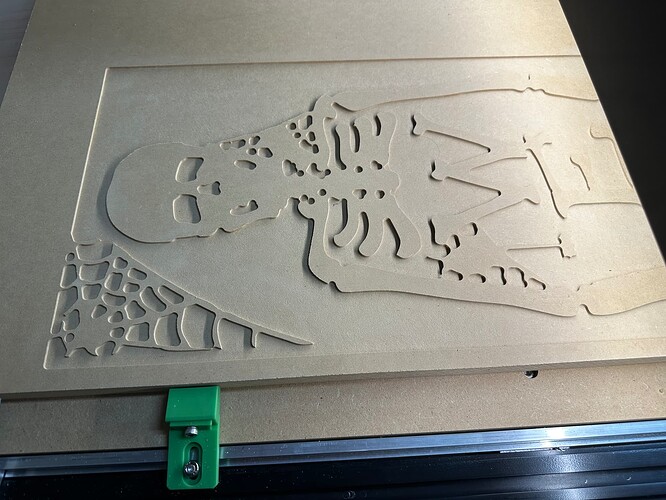

From this point forward, all jobs are tiled and the second part of each tile is setup by sliding the material forward so that the first tile overhangs the front of the machine but the zero’ing hole is still within the machining boundary. I have a SMW bed and used 3 vices mounted in the bed to form the fence that I slid the material along. For a sacrificial wasteboard, I have a couple of HDPE cutting boards that I mount over the aluminum bed.

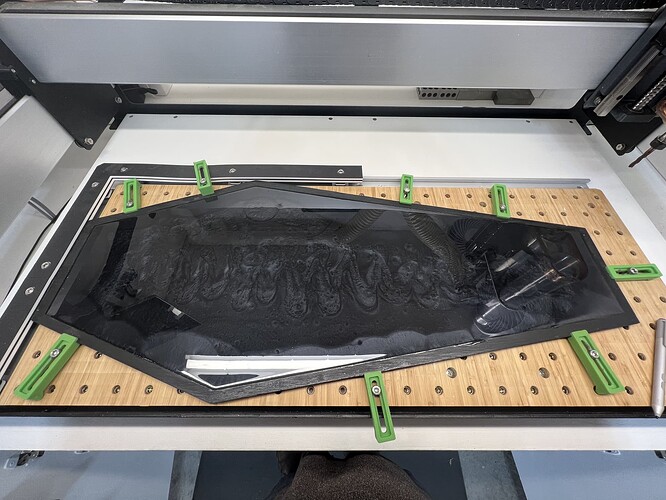

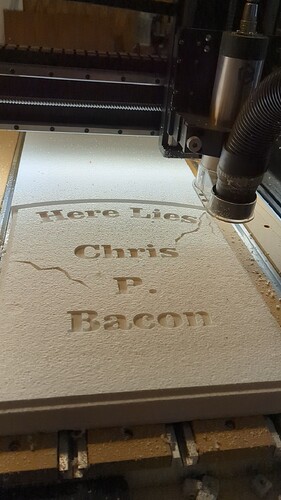

- Carve out all the black areas in tile 1. I setup the carve to carve excess areas where the tool wouldn’t be able to reach since I was coming back to do a more precise carve for the white later.

- Ditto for tile 2.

Pour all the black epoxy and let it cure.

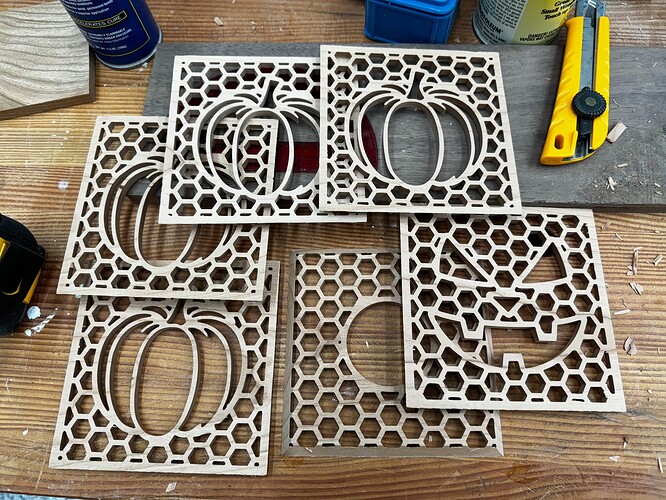

- Carve out all the white areas in tile 1. I ended up using 1/4" and 1/8" o-flute endmills and a 2mm 3 flute endmill to get into the very small areas. Where the very tiny points meet on the outer edge, I took advantage of the overpour area and cut a little excess area around the spinner to give me a crisp point.

- Ditto for tile 2

Pour the white epoxy.

- Through cut the outer profile with tabs to hole it in place in tile 1.

- Ditto for tile 2.

I learned a ton on this project. I learned that 1/2" PVC panel purchased from a big box store is incredibly warped. I struggled a lot with work holding. I used double sided tape to hold it down and then added some hold down clamps in some places that were prone to warping off the double sided tape including a few custom 3d printed clips holding the front of the material down. If I were to do this again, I would probably take 3/4" PVC trim board and glue up a large enough piece so that I could surface both sides to get a flatter project.

This was also my first attempt at pouring epoxy. I have poured other polyurethane plastics using molds in the past so it wasn’t completely foreign but I had to figure out a process for actually doing these pours. I ran through a series of test projects to figure out fun details like that the cheap measuring cup which came with the beginner epoxy kit was horribly inaccurate and combining information in the internet to derive a weight based measurement to solve problems I was having with the pour not curing properly.

I’m not going to bother including the design file as this was all done in Fusion 360 and is made up of several files combining the 3d parts and the CNC parts. If someone ends up doing something that is similar, let me know and I’ll try to pull all the files together for you.