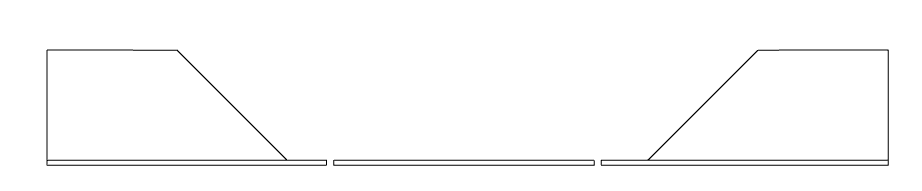

What caused this deformation, on the reverse side, instead of cutting completely through? I cut this with a 1/32” end mill, 2 flutes, depth per pass .003, plunge rate 1.8, feed rate 5.0, RPM 18000. Set to cut to the bottom of the metal .0410”. Thanks.

What alloy of copper? How machinable is that alloy?

What sort of toolpath?

Oxygen free copper reported to have good machinability (between 200-500 sfm). Contour toolpath.

I wonder if the tip of the flutes are dull or maybe the depth is too shallow once you get towards the bottom of the material ![]()

I could imagine the material deflecting/being pushed around if the cutting edges aren’t quite biting. Maybe it cuts up to this point because the material under the cut provides enough rigidity to allow a bite?

All just theory, I’ve admittedly got very little experience in sheet metal.

First use of the end mill from Carbide 3d so I hope it hasn’t dulled during that time.

Maybe dull isn’t the right word to use. There is some relationship between the radius of the cutting edge and the formation of a chip in a given material at a given feed/speed. So a cutting edge might be plenty sharp to make good chips in one material but not sharp enough for another…though I might just overthinking it.

(Bpedit probably has much more insight here and I’m looking forward to seeing what they have to say ![]() )

)

What sort of work holding were you using? Your final pass was over very thin metal, easy to see that deforming the copper. When I’ve cut thin soft metals, I’ve cut slightly deeper than the thickness to be sure to get a clean line at the bottom.

Funny, I had just typed my reply when your’s came up. Thanks but your analysis is way beyond my purview!

Blue tape on both the metal and waste board held together by crazy glue.

I was just in the process of making a design to try different depths to see what works. Do you have a rule-of-thumb gestimate of how much more to add to the thickness?

Your chipload is 0.00014", pretty small. consider bumping up the feedrate or slowing down the spindle a bit. I know it’s nerve-racking with that small of a cutter. Even as small as the chips are, they should still be well defined chips.

Copper is soft and will just do this. Something is allowing the material to deform downward, or the stock to lift upward. Consider how rigid the material below your stock is, and your workholding as Byrne mentions. If I had enough of these to do I might consider an additional hold down block / mask on top of the part.

Quick aside, you might want to try some machinable wax fixturing which would allow you to cut through cleanly without the risk of “gumming up” your cutting tool. The wax can be a bit of a hassle but it’s a cool tool to have in the toolbelt ![]()

Note that we do stock that:

Interesting comment about the wax. I have that but during a phone call with Carbide 3d was told to hold my piece using the blue tape method instead. Can you clarify why one over the other?

Thanks, will try. Would “a bit” be something like 15000?

That would bring chipload up to .00017". I think Winston had some good numbers for copper. Not sure if he went that small of tool though.

There is a video on this material at:

Thanks. Have watched some of these but will watch again.

Question about the 10000 rpm he uses and a conversation with Precise Bits. Precise Bits recommended a higher rpm than 10000 but didn’t give me a specific recommendation–just higher.

I wondered if the 10000rpm recommendation by Winston is because the previous Nomad ran at a slower speed and that is the highest speed that model could operate at?

Yes, that sounds correct for the RPM speed choice — hopefully @wmoy can chime in here as well.

You hit the nail on the head re rpm. He almost certainly used 10,000 because that was the max speed of the previous nomad.

Regarding precise bits, in my experience those folks really know their stuff. They also seem to have much more expertise in micro machining than most tool makers I’ve talked to. (Which is only a handful but still ![]() )

)

Point being, if they’ve got advice to offer it’s probably worth pursuing.

My take is that the wax fully supports the material through the entire cut whereas blue tape will shift out of the way. EG blue tape can compress where wax will not.

Then there’s the benefit of wax cutting cleanly if you do need to punch through the bottom of your stock. Which may or may not be necessary given the additional support that wax offers.

Blue tape is usually a decent method for thin materials with a lot of surface area and light cuts. So it’s not surprising they offered that solution first. Quick, cheap, easy, and works the majority of the time.

IMO: You’re in a bit of a weird place with that material and cutter combination…not that it can’t be done, just that it’s not terribly common so you’re in for some experimentation ![]()

Thanks! That makes sense—blue tape compressing vs the more rigid blue holding wax.

The person I spoke to at Precise Bits was both patient and helpful with a total newbie. Their comments got me off into understanding a little more about chip loads, feeds & speeds, etc. I found Will’s books to be a very good resource too.

I think I will be getting even more into a weird area. I am using copper as a learning tool. My reason for buying the Nomad is to cut sterling and fine silver.