I am fairly new to the CNC world and am learning a lot, so this may be a dumb question, But here it goes anyway,

When looking for different projects and ideas, many of them come up and say for laser cutting. I am definitely not ready for laser, I know the SVG files will open in Carbide Create, but will these projects that are designed for laser cutting still be able to be cut on a Shapeoko Pro using the router instead of a laser? If yes, what do I need to know to do this. My thought is I may have to go in and provide additional separation to the parts as it looks like the laser cuts are set up a lot closer together and may cause an issue with a 1/8" endmill. Any advice would be wonderful. Sorry if this seems to be a real newbie question.

Hey Ray,

So i’ve been using my CNC for 9 months and i’ve downloaded some of these files, the main issue you will run into is corners or turns too tight for the size of bit you are using. i.e a 1/8" bit wont be able to get right into a 1/32" Radius corner.

if its a several part project I would recommend importing it, moving the parts around/apart from each other at least 1.5x the tool diameter and creating a cut out toolpath with your 1/8" and another with a 1/16" if you have one so you can see if there is any difference. If you are cutting out several pieces definitely use tabs to hold it all together as the skeleton can get flexible if you remove too much in 1 go without tabs as scaffolding. If the parts are quite free flowing without tight corners then im sure you will be fine with the 1/8". you will be able to adjust nodes to remove these tight area’s too.

Do you have a screenshot of the design so I can try offer some more info?

If it’s a decorative design you might be able to get away w/ using a drag knife or diamond drag engraver.

If you’d let us know what sort of design you want to make we might be able to work up some alternative.

Note that there are collections of designs for routers such as:

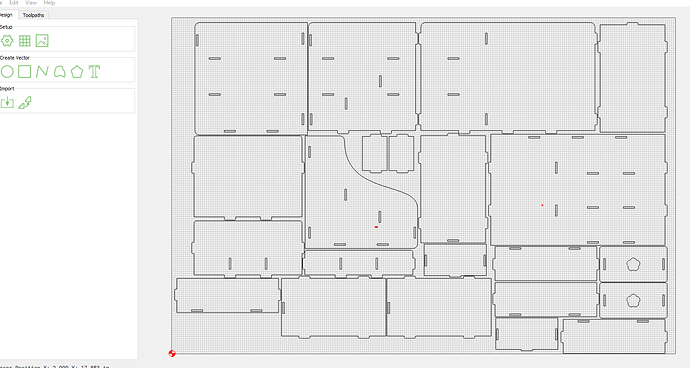

Here is a screenshot of what I wanting to do. This is in Carbide Create. Currently set up as 33"W by 22"H

That design would need to be adjusted to account for the radius of the V endmill.

One approach for that would be to use a V endmill or a cove radius endmill to relieve things — for doing this with box joints, see:

or

For doing this with mortise and tenon joints see:

btw there is a thing you can do in CC to adjust vectors for a specific bit size (mostly useful for inlays):

Assuming a 1/8" bit:

Select the vector(s) you want to adjust

Use the offset tool and do an outside offset for 1/16"

Group this result (for convenience)

Use the offset tool and do an inside offset for 1/8" of this new group

Group this result as well (for convenience)

Then use the offset tool and do an outside offset for 1/16"

Group this result for convenience

Delete the groups from the first 2 offset operations

This “grow - shrink - grow” step gets you a design of the same size ( + 1/16 - 1/8 + 1/16 = 0)

but due to how the offset tool works, the corners get rounded to the tool size.

Note that geometry that is too small to be cut by the tool will disappear if you do this; this really is going to leave the cutable shape.

Oh and 1/8" is very nice and sturdy while 1/16" is approaching the fragile range. I found that a metric sized 2mm bit is ideal, it’s still sturdy (so does not snap as easily) especially for deeper cuts, while still being really smaller than 1/8" so finer details like text look much much better.

Alternatively you could create dog bone shapes off each internal corner. That’s what I did with this making small semi circles on the inside of each corner which were 3.3mm dia using a 3.125mm bit. Workes great. Can fill holes with wood filler or even glue if you like prior to painting/finishing

Looks interesting. What are you trying to make?

You probably already realize this, but don’t forget to adjust the width of the slots to your actual material thickness. This can be rather tedious because there are a lot of slots in your layout.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.