Hey guys  .

.

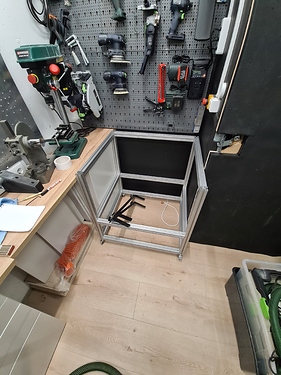

My shapeoko is running beautifully since a while and hat a lot to build and thinker so my updates got a little abandoned. Now I am back and better then ever  . Enclosure was running on my workbench for a while now and that has to end… I finally managed to start building my enclosure of 40*40 aluminium extrusion. I had to switch design a bit because the planned spot wasn’t working out and my workshop is only 6sqm large so modularity is key when I’m working…

. Enclosure was running on my workbench for a while now and that has to end… I finally managed to start building my enclosure of 40*40 aluminium extrusion. I had to switch design a bit because the planned spot wasn’t working out and my workshop is only 6sqm large so modularity is key when I’m working…

My enclosure is now on rolls with a shelf under the enclosure. The shapeoko is barely fitting inside so that it can squeeze into its desired spot. Had to make some adjustments to my worktop as well but just tiny things. Now everything fits.

For the baseplate and the lower plate I ordered 8mm steel to ensure that the machine housing weighs a ton and doesn’t move. They should arrive next week. Update will follow.