Thanks for the sanity check! You made me look back at some of my old cutting force measurement results. Those results suggest that conventional milling forces are equal to or slightly higher than climb forces in both poplar and MDF at 50% Diameter width of cut. Since the magnitude of the cutting forces and powers generally correlate quite well with the MRR, maybe the slight conventional milling increase is caused by rubbing?

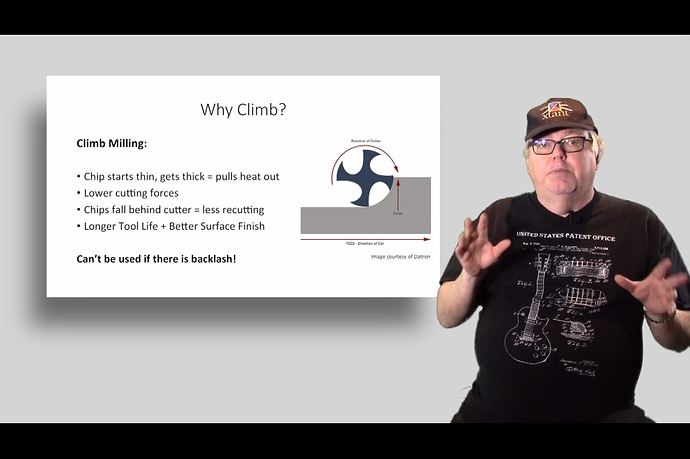

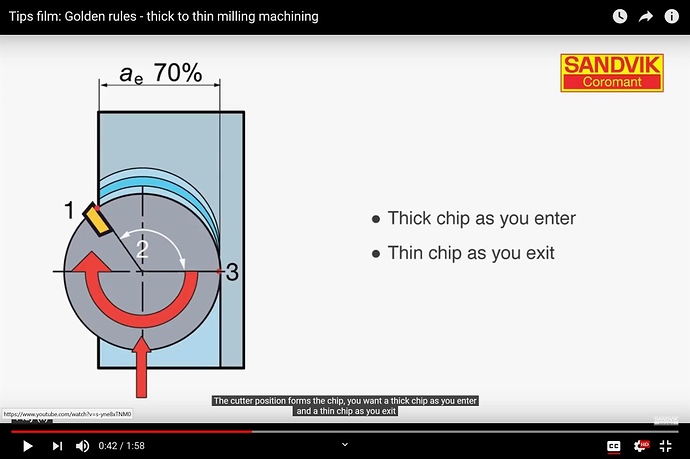

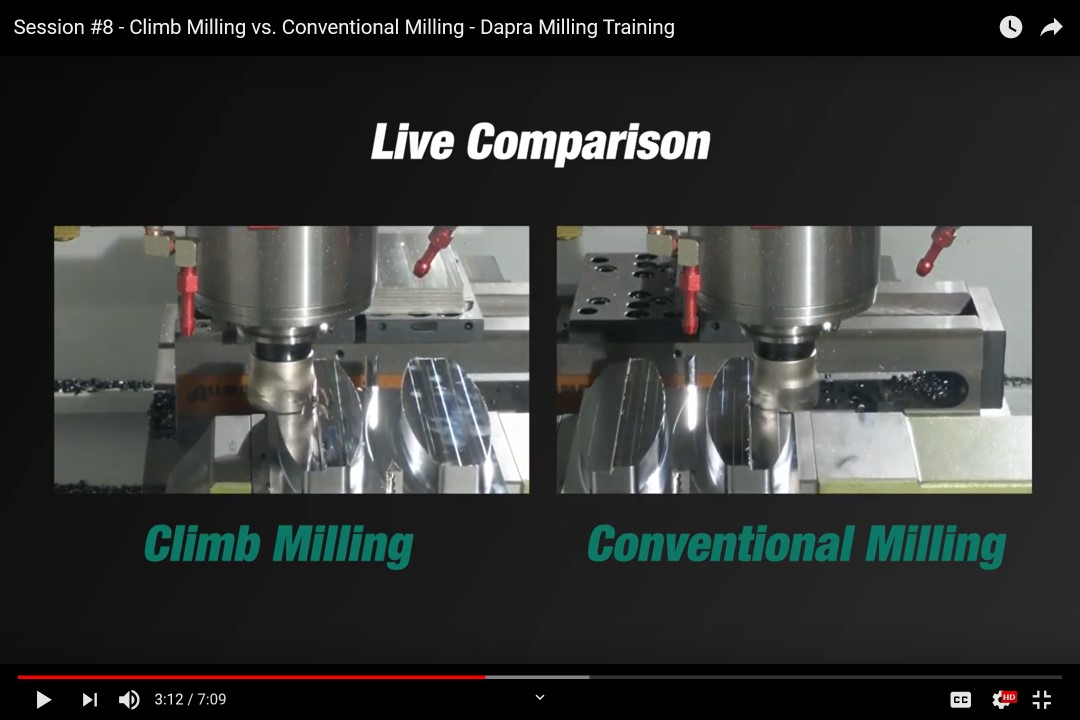

Unless I’m missing something, you’re linked BW article seems inconsistent with Sandvic’s discussion of climb vs. conventional milling and the Datron source BW references. I wonder how that apparent discrepancy impacts the remainder of their discussions. IMO this video does a much better job of defining, showing, and explaining the differences and pros/cons of the two approaches. So, you should almost always “Drive on the right side of the road”. ![]() (Unless you’re a counter-clockwise rotating hurricane climbing the East coast.) Note that there is no mention of backlash.

(Unless you’re a counter-clockwise rotating hurricane climbing the East coast.) Note that there is no mention of backlash.