Minor update:

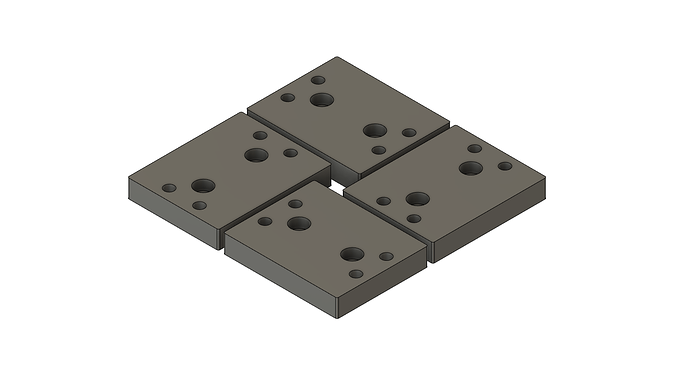

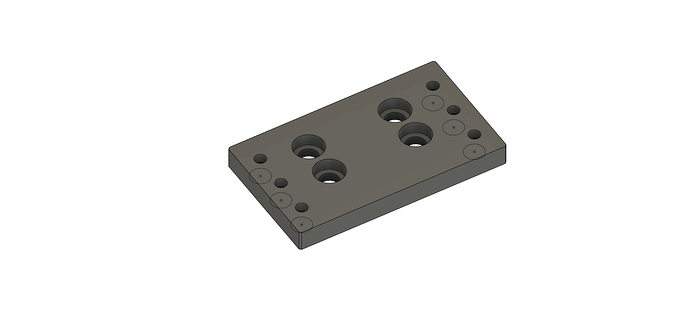

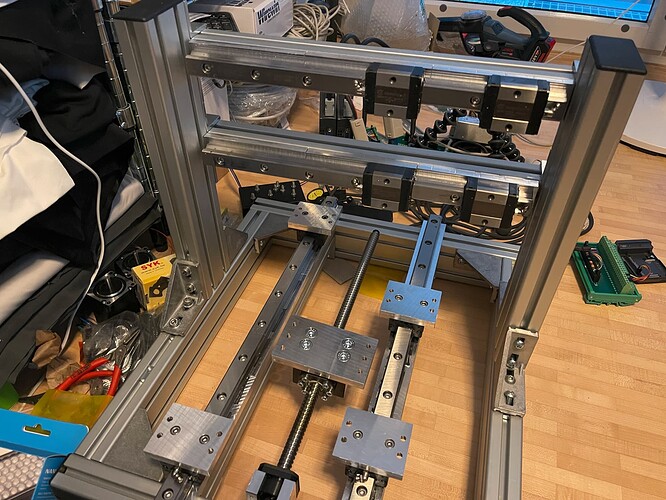

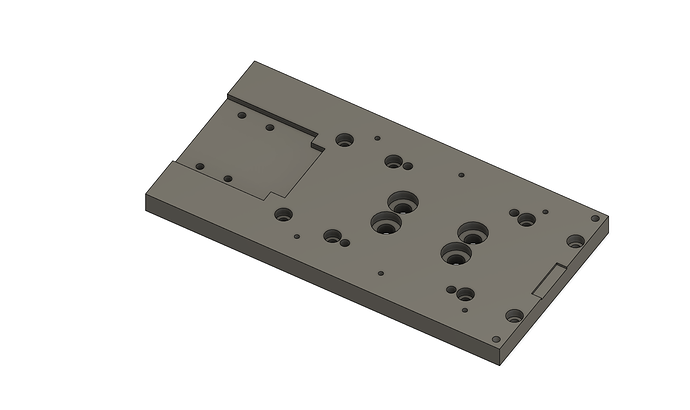

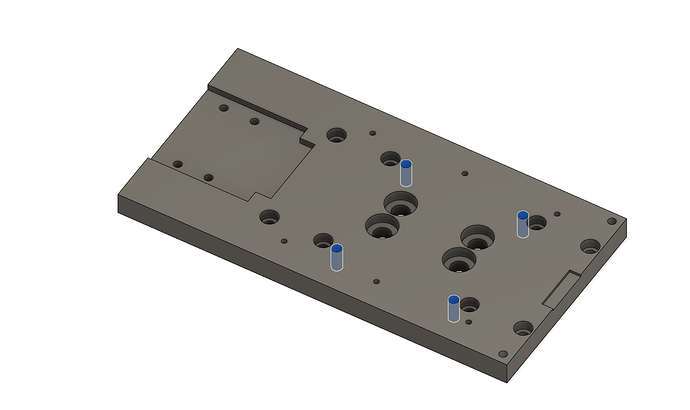

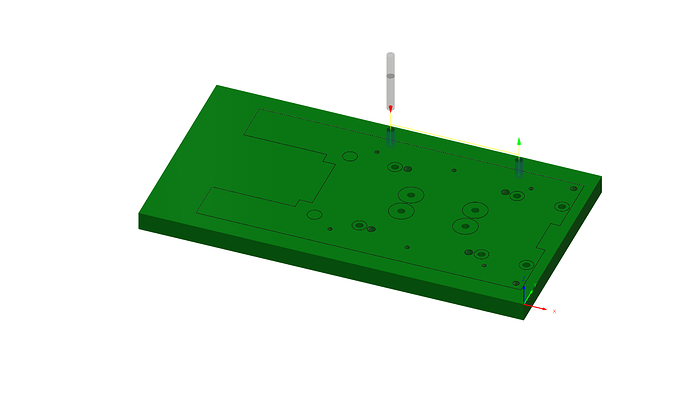

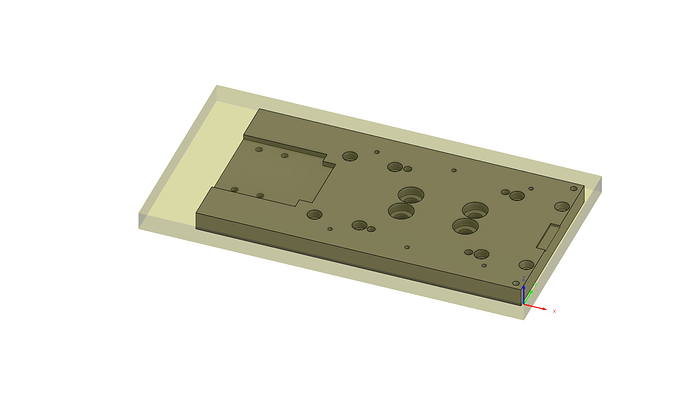

I milled the spacer plates for the X-axis:

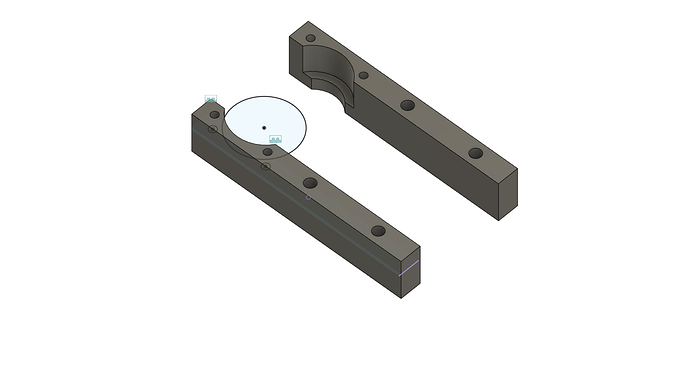

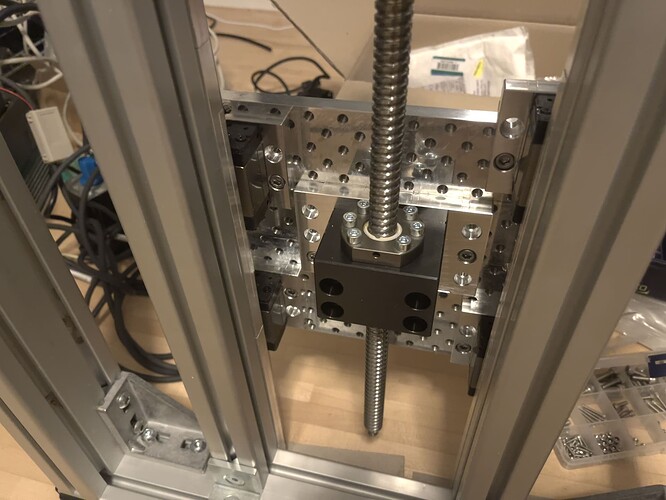

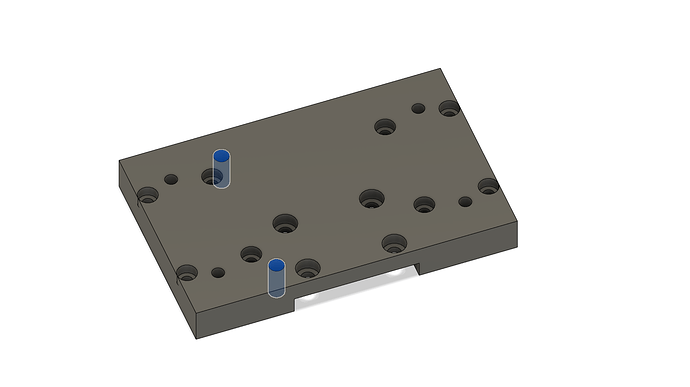

For the Y-axis, I milled them individually because that was really the only way to go about it. The Y-axis is 600mm long so the plates each need to be nearly 200mm.

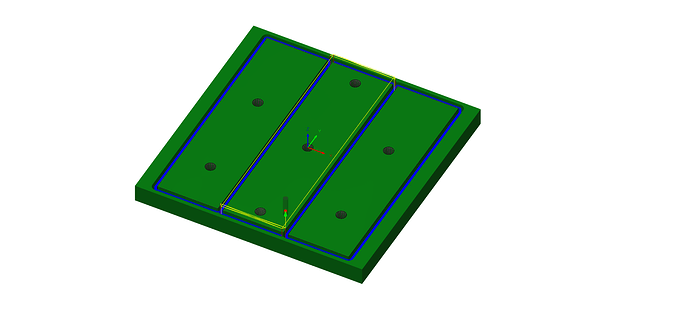

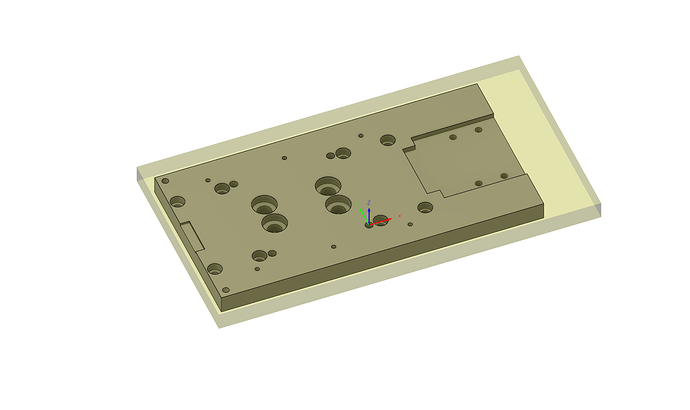

But the X-axis is only 420mm long, so each plate only needed to be ~140mm long and I could fit 3 of them in a standard (for me) 150mm plate:

That standard plate comes with a parallelism tolerance of 0.50 mm/m so for a 150mm plate, there’s a maximum of 0.075mm variation instead of the thickness tolerance of ±0.1mm. Half the shims!

I also “discovered” an easy way to zero against stock that hadn’t occurred to me before: when you can constrain two of your axes (e.g. a loose vise constrains X, gravity constrains Z but the workpiece is free to slide along Y), you can easily “zero” the mill by moving to a fixed position offset by the tool radius, then pushing the stock so that it touches the tool, then securing it.

That method is super handy if you need to mill a bunch of pieces of stock that are the same size.

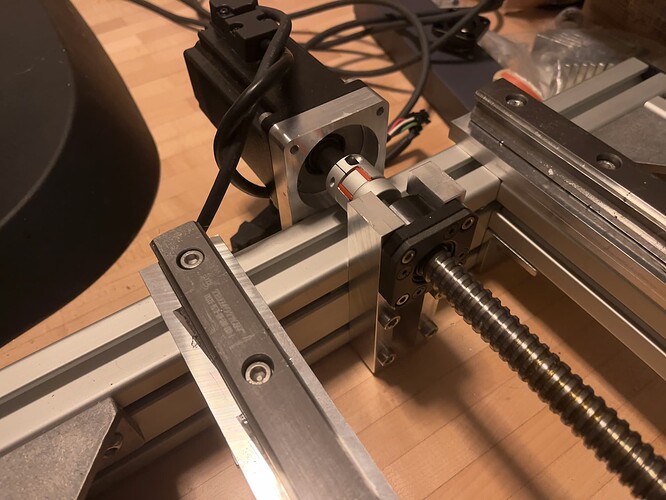

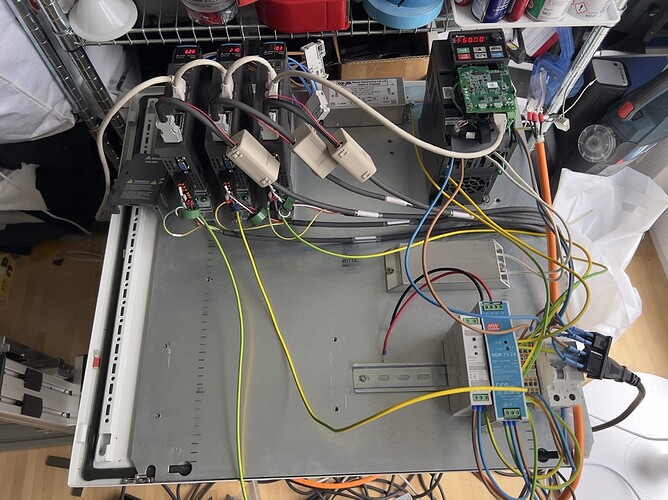

On controls, I prepared a PC with LinuxCNC and ordered a Mesa 7i76e.

On servos, I did try to play with the servo tuning a bit but the built-in USB interface kept crashing as soon as I switched the servo on. I think there’s a bunch of interference happening and getting in the way. I managed to get the RS-485 interface working but only at low baud rates. Turns out RS-485 is super picky and wants things like termination resistors that I’ve never had to bother with before. So I’ll add some resistors at some point.

I also have a Vers TSM toolsetter sitting around. Unfortunately I haven’t been able to play with it much because it requires that I turn the spindle on in reverse and I never wired it up. “Why would I want to put the spindle in reverse” were my thoughts when I was wiring up the controller.

I’m also contemplating ATC for this machine. There are two options I’m considering:

-

Spindtech ISO10, 800W: Funnily enough, this is actually the perfect size to swap out for my Mechatron spindle. I could make an ATC Nomad. It’s a bit pricy though.

-

Jianken JGL-80 ISO20, 1.5kW/2.2kW: Cheaper than the Spindtech, more powerful and with a somewhat normal toolholder (try to find ISO10 toolholders, basically only Schaublin makes them). Not sure yet whether my mill will be able to throw an 8kg spindle around though.

I’ve been looking at vacuum pumps too. Turns out I can probably buy a decent rotary vane vacuum pump for ~200EUR.

I also need to figure out what to do about the bed. The SMW bed I’m using from my Nomad is too small. I’m wondering about repurposing a Shapeoko bed. It’ll “only” be 300x300mm but I’m not sure what alternatives I have.

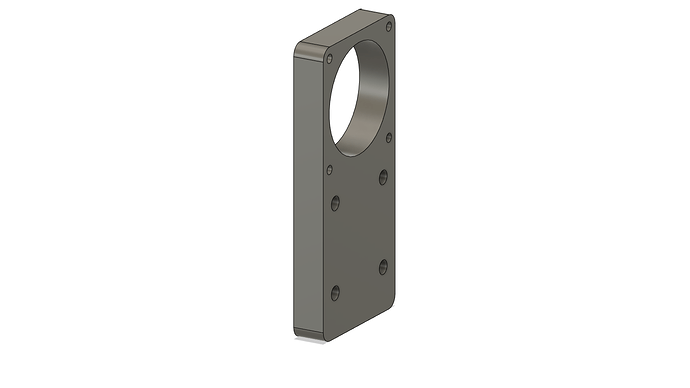

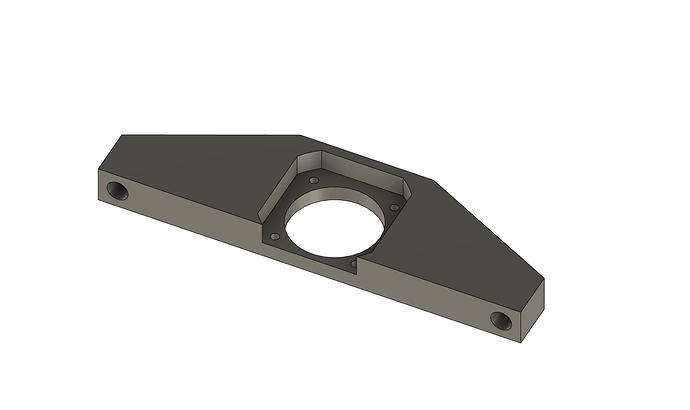

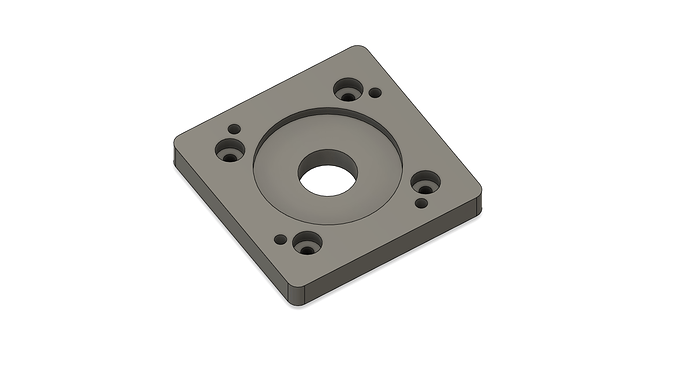

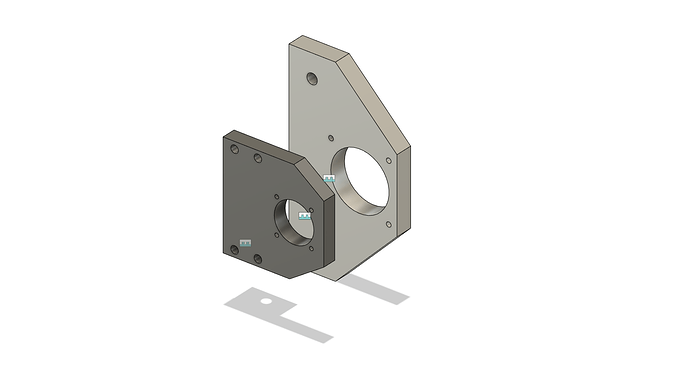

And finally, I need to figure out what to do about the Z-axis. Ideally, I’d modify the existing Z-axis plate. There’s a problem though: that plate is mounted to the machine I need to use to mill it. I’ll probably need to mill a new plate and buy a new motor bracket. While I’m at it I’m wondering if I should add a little more Z-axis travel and beef up the linear rails and ballscrew.

That’s enough ranting for now though…