I’m looking to upgrade, to a spindle.

Do I need an HDZ upgrade, or will the stock z axis do the job? I have no plans for anything other than wood, and am wanting something a little quieter, than the router.

Is water cooled worth the hassle dealing with water, or is air cooled sufficient?

Water cooled and quiet go together. Air cooled and noisier do too.

I just ordered an 800w water cooled spindle and I think the basic machine could handle that. I’d not go larger than that without an HDZ but that’s just my opinion. I did upgrade to an HDZ and love it.

How bit shank bits do you want to use? The 800W spindle will only do ER11 chucks with is basically 1/4". The 1.5KW spindle will do around 3/8" shank bits and the 2.2KW spindle will do 1/2" shank bits. Those are estimates but they’re close.

I’m just setting up my machine, but I will be using 1/4 - 1/8 shank.

The bigger spindle with HDZ seems like a lot of weight for the stock XXL. But I like the idea of being able to handle a 1/2” spiral bit.

I’m concerned that if I add HDZ, 2.2 kw spindle and start pushing 1/2” bit around, I might be asking the machine to do more then it was designed for.

What’s the make of your 800 watt spindle?

You might want to set your stock machine up and develop some baseline performance parameters for materials/jobs you do most often. The stock SO3 is a very capable machine.

That said, it’s also quite hackable. Check around the forum. You’ll find a LOT of information on spindle swaps from 800 watts to 2.2kw not to mention laser mods, linear rails and so on.

We’re here to help.

My 800w spindle is still on it’s way from China to me. I’m hoping to be able to put it under the tree for Christmas…

I ran a 1.5kw air cooled spindle on the stock z axis on my XXL for some time, no issues at all. Go for the 65mm diameter spindles so you can keep the standard spindle/router mount.

It’s a great feature Having the machine switch the spindle on at the start of a job and off at the end

Standard (including straight) woodworking router bits can be used on Shapeokos. Unlike endmills, their cutting diameters aren’t limited by router/spindle collet sizes. Material removal rates (MRRs) on Shapeokos is limited by machine force/rigidity rather than router/spindle power. Done properly, increasing cutting diameters enables higher MRRs by increasing router/spindle power usage instead of machine force. You may well find that you won’t need HDZ or a higher power router/spindle. The advantage of water or electric fan cooled HF spindles is that they are a lot quieter and are supposed to be rated on output power rather than input power like routers are. So, at its rated speed, a “800 Watt” HF spindle should have about the same output power as a “2 Horsepower” router. But, since Chinese HF spindle manufacturers don’t provide meaningful performance data, who knows about them!

Stu, Was that air cooled spindle close to same noise as one of the routers? I KNOW water cooled is going to be quieter, but is it enough to warrant the trouble dealing with water? Very limited data that I’ve been able to obtain other that ‘louder than water cooled’. I’m going to use my dewalt until it fails, but I’m not convinced I want to go to water cooled.

John, while I haven’t heard a water cooled spindle, the air cooled one I’ve got is much quieter than my makita router.

If you’re not keen to commit to a watercooling system, the air cooled spindle is a good compromise, plus in future if you decide you do want to go water cooled, you can use the same vfd and just buy a new spindle. I’ve read that it’s generally the bearings that go first in the spindle setups… I’ve been running my spindle for about 3 years with no issues at all

Thanks for the comments. Noise is not as much as an issue as a it more power and just eliminating the router. I use VFDs on several other woodworking machines and I love how they work. (for that matter, my new dust collector is run by vfd also.) I do love how you can run them via the low voltage wiring. I’ve a lathe that I can reverse and change speeds with a wired remote. Nifty things. And those attributes are what I’m looking for with a spindle. Not really dealing with water and potential freezing/leaking.

I agree, I’m going to get started with the stock router, learn the the machine/software and its capabilities.

I am courious to know if anyone has any experience with the 1.5 MySweety spindles.

No experience with those.

For about $30 more (shipping is a bit expensive) you could get a 220v er20 size package from AliExpress.

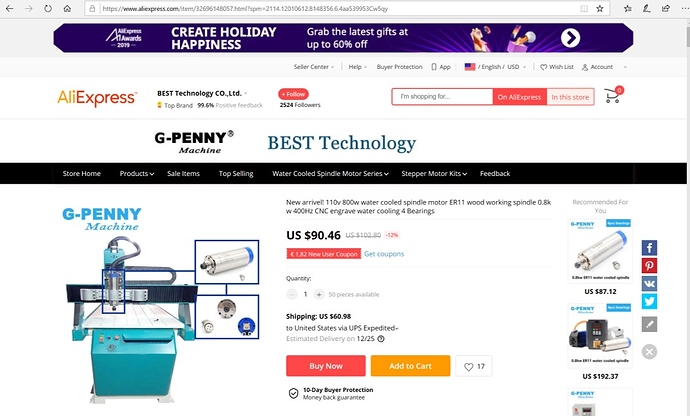

Several of the folks in the forum (myself included) have these G-Penny spindles. @Julien has documented setting the VFD up. You also have the option to select steel or ceramic bearings.

If you go with the 110v be sure to check the amp load, I know some folks have had to upgrade their wiring to handle the load.

YUP - 1500 Watts of output power would likely require at least 2500 Watts of input power. So he’d need at least a 20 Amp 120V circuit to get full power out of it.

IMO something like this 800 Watt G-Penny spindle should have more than enough power and would likely be much more compatible with stock Shapeokos setups.

Nice cooling setup - you should share details!

Yeah that is pretty slick, the Axiom Precision machines use a really compact closed loop setup, I can’t get any info on it other than a few obscure photos.

When my air cooled one dies I’ll likely look at a watercooled one with a small tidy cooling setup

Thanks but…copied a setup from one of @Luke posts, nothing original here. Plus, my stuff’s not very sexy, just get it done.

So I’m actually trying one of the CW3000 units. It works in the same way, but is a large unit you put somewhere. Whilst I liked my DIY setup I needed another couple for some projects and I think the CW3000’s are cheaper than a DIY approach…

Actually not a bad idea, these are more for smaller lasers, as they are just radiators, no compressor like the cw5000 or larger. And even the knockoffs should work well for a cnc…

Keep some JB weld on hand. I had one develop several leaks on the coil.

Give us some context here please. The CW3000 I just googled is for a CO2 laser and costs a couple of hundred bucks. You’re not proposing this as a add on to a water cooled spindle…or are you? Or, is there another CW3000 for spindle cooling and I found the wrong one?