Probably easiest if you don’t want to wire the 220, as said before, you won’t be pulling the full power anyway.

Sounds like running on 110v would be easier.

But for future reference:. 2200watts divided by 220 v= 10 amps. They do make 15 amp 220 plugs and #14 wire is acceptable for 15 amps. The vfd and spindle may not pull 10 amps contionusly but you have to plan for peak amperage during startup.

The inrush surge can be a problem on a traditional motor but all the VFDs I’ve seen have been soft start, i.e. they start the VFD first, generally with a power limiter for a few seconds to charge up the main capacitors without popping a breaker. They then start the motor slowly and ramp to speed rather than trying to immediately go to full speed.

Both of those mean that there’s no big turn on power surge to the VFD.

Liam what you said about the vfd is true. However an electrical outlet can have other appliances plugged in to it. Although the user may never use it for something else you never know. Here in the US the smallest breaker is 15 amp for 110/220vac. I have a 220vac 20 amp plug for my 12 amp table saw that I also use for a 220vac air compressor used for sand blasting. I also have 30 amp 220vac plug for my 4.8 hp band saw. I also use that 30 amp plug for my cousin’s RV when they come to stay.

When you have a 220 plug in a shop you find a lot of uses for it.

This thread is why I hate Chinese crap. They only give you parts of the puzzle. VFDs are inherently power losers. they rate the vfd to the Spindle and give out a high power rating that is almost impossible to achieve using 110v input. But I would use a 110v if that is what came with the Spindle. 15 amps will be enough. I’ve been using US made vfds on my woodworking tools for over a decade. Great devices when used and wired properly.

I have the 2.2kw HY 110vac VFD and I break end mills on our SO3 before tripping breakers. I also have wired up 220V lines for my jointer, planer, and dust collector. Either route would be fine, in my opinion.

Let me know if you have any questions with the new 110v VFD you ordered.

Other than routers, RC (inrunner/outrunner) DC motors, and some Chinese HF spindles (and some other Chinese motors?), motors are rated on their output rather than their input power. So, a properly rated 2200W, 220V, 8A 3 phase motor would require 220V X 8A X sqrt (3) = 3048VA input for 2200W (2.95HP) output. That’s 12.7A at 240V and 25.4A at 120V. @Liam’s HY VFD (for 2200W HF spindles) reportedly can supply up to 4400VA. If that VFD is 90% efficient, it would need 4400VA / 0.9 = 4889VA, or 4889VA / 240V = 20.37A or 4889VA / 120V = 40.74A to provide that output. AFAIK, residential wiring in US residences is limited to 30A for 240V circuits (10 AWG) and either 20A (12 AWG) or 15A (14 AWG) for 120V circuits.

Have you ever looked at how much power you’re VFD is drawing, or how much current your motor is drawing?

I haven’t but I’d be open to do so with some guidance on the best way to record that data.

Here’s one way (plug your VFD into one of those types of power meters). Your VFD should also be able to display current into the motor like shown here, but you probably won’t see much increase there when cutting at the power levels you’re likely using.

Yep,

If you have a HuanYang then pressing shift until you get a single red LED under “A” above the numbers will show you the amps to the motor.

Be aware this won’t start at zero for zero spindle torque so set the speed, see what the Amps are and make this your zero, the additional Amps for spindle torque are roughly linear from there up for the same RPM.

e.g. mine says 1.8A for most normal speeds at no load so when I get 2.1A cutting that’s 0.3A of cutting current.

To turn that into power is a bit more complicated and it’s much easier to just put a real power meter upstream of the VFD.

These things you have are all sockets, not plugs, no? (or ‘outlets’ in US parlance)

Yes they are all female sockets. The 20 amp 220 is a 3 prong and the 30 amp 220 is a 4 prong. Very seldom is equipment hard wired. In industrial settings machines are hardwired but in homes and garages/shops they are usually sockets and machines have cords with male plugs on them. Every country have thier own standards. In US we have national codes but each area has standards which conform but may add requirements per local building codes.

Good to know… I thought it odd when you described them as plugs.

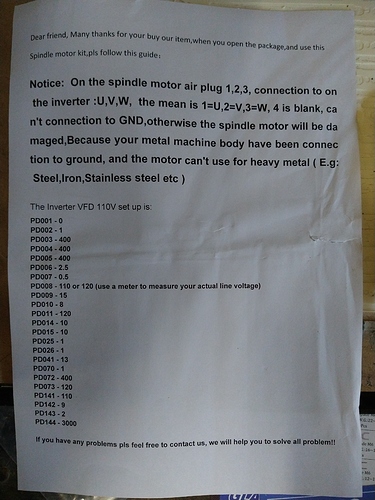

My replacement spindle and VFD came with these cryptic instructions. Everything seems right except the bit that says I should NOT ground my spindle. WTF? I am assuming this is a translation issue and that I should still wire the ground pin from the spindle to the ground of the VFD, what do you guys think?

I think the “Because your metal machine body have been connected to ground” is saying that you’d create a ground loop by connecting the VFD ground to the spindle casing at the same time as grounding the machine from another point.

I would not run a VFD spindle without the casing grounded, they are not exactly double insulated.

EDIT - for a little more info on that, an RCD / GFCI won’t protect from faults in the VFD output or spindle, even if they’re detected the VFD stores enough energy to kill you quite a few times over internally. Only grounding the machine and spindle shell effectively provides any useful electrical safety, unless you really want to trust the wiring in the spindle…

yeah, so I figure I’ll ground the VFD and spindle into separate outlets just in case.

Separate grounds may well be the issue the vendor is trying to avoid, might be worth asking them what to do if the spindle mount is not already grounded.

This might be useful;

This topic was automatically closed after 30 days. New replies are no longer allowed.