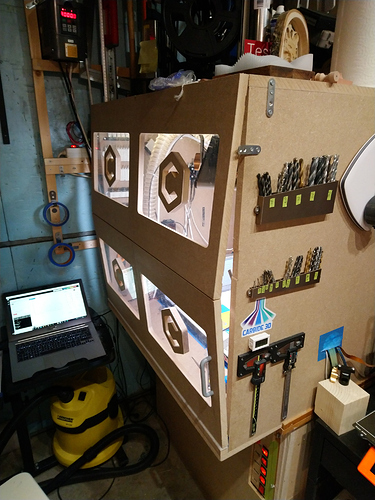

The front door/window of my enclosure used to be a single giant panel that I would put in place/remove by lifting the whole thing and putting it somewhere nearby on the floor. It was the most inconvenient thing one could think of (but…lazyness and no interest in making a proper door earlier)

I don’t have enough space around the machine to make regular doors, so I went with something that would open vertically, with hinges at the top.

I checked what thick MDF sheets I had left…and of course I had no piece large enough to fit my enclosure dimensions. But I did have pieces large enough to make four quadrants that I could assemble, so I did that.

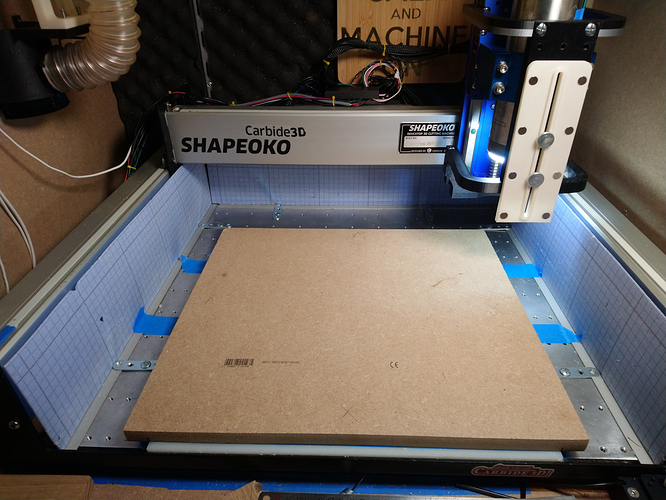

Cutting each quadrant was an “interesting” exercize since their dimensions happened to be at the extreme limits of what my SO3 can cut:

That’s my wasteboard in white under there, and I needed to cut up to the edge of the MDF. I should have taken a picture, I ended up having 1mm  margin on the left AND the right side…it required very careful positioning of the stock. Oh, and when you’re at the work area limit like that ? Probing XYZ on the lower left corner makes for an interesting crash against the left rail

margin on the left AND the right side…it required very careful positioning of the stock. Oh, and when you’re at the work area limit like that ? Probing XYZ on the lower left corner makes for an interesting crash against the left rail

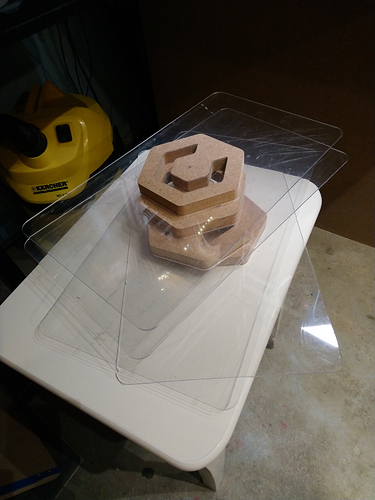

Anyway, I cut the four quadrants, and stitched them together (yes, one of those is crooked)

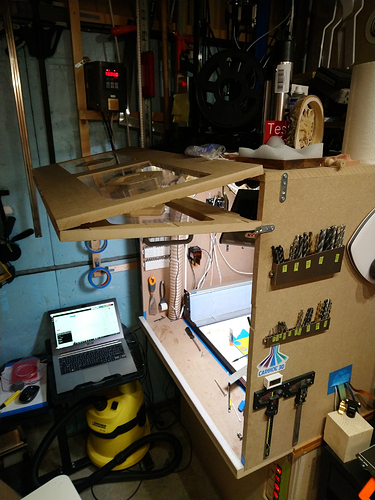

I added the hinges, and installed this thing on the front of my enclosure:

I reused the old scratched acrylic window pane from my previous door to cut smaller windows out of it, and I thought, let’s have a little fun and insert & glue an MDF piece inside a cutout in the acrylic:

The hinges work exactly like I wanted:

I added a strip of cushion/foam at the bottom, so when I close the door, there is just enough resistance that initially the door is like this,

and a small push locks it in place nicely:

Just a door, but a fun week-end project overall.