i have this message and i use carbide motion 417 because i have HDZ. what is the solution

When do you get the error?

i can jog and do my zero setting. when i start the print i got error 10

Please post the file you’re trying to send.

Kevin.nc (2.7 MB)

The file seems fine.

Please transcribe the error accurately and completely or take a screen grab or photo of it.

I suspect you’re having an EMI problem.

If i have a EMI problems what are the solutions

For EMI, the boilerplate response is:

Apparently your machine is experiencing electro-magnetic interference — please try the following things which you feel apply to your situation and which you are comfortable doing (and have not already tried). If your machine has been used successfully for a time, check the carbon brushes in your spindle (trim router) per your owner’s manual.

Start at step 1 and work your way down:

- arrange the AC cable for the spindle (trim router) so that it doesn’t cross or be near any of the other cables

- if you’re using a laptop, ensure that it is plugged in, preferably to a grounded outlet using a 3 prong plug if possible

- if you’re using a USB extension cable or unpowered USB hub, please directly connect the machine using a shorter than 6 foot USB cable — if your cable doesn’t have a toroid (metal cylinder often molded into the end of the cable) and you have a cable which has that feature, try it, if not consider adding one or getting a cable which has that feature

- try a different USB port, esp. if you have the option to switch from USB3 to USB2 — if using a laptop try a good-quality powered USB hub — some laptops undervolt the USB ports to save power. Make sure that the cable isn’t being jostled or disturbed.

- if your spindle (trim router) power cable doesn’t have a toroid, try adding one (note that what seems to be a toroid on most trim routers is actually an anti-theft device on all the ones I’ve seen). Note that worn carbon brushes or a loose connector on a trim router may cause arcing which results in EMI.

- if possible, connect the spindle (trim router) and the machine through a different circuit

- if you have a surge protector, please connect the machine through it

- check the ambient humidity, if low, consider a humidifier

- if using dust collection, ensure that your dust hose does not allow static build-up, or is properly grounded

- Connect the machine with a galvanic isolator such as this one: https://www.adafruit.com/product/2107?gclid=Cj0KCQiA5aTUBRC2ARIsAPoPJk_QzQ3Qjm2-l-wyL9heIWt_62QGVKLz2u_ytQJiniXgGNuPTVyfUI8aAi7qEALw_wcB

Please ensure that there aren’t any extraneous wires which create ground loops (the default configuration doesn’t have this problem but folks have introduced it when adding dust collection, or trying to ground things themselves).

I would add one other thing to try first on Will’s list.

Switch off any nearby devices that could be a source of EMI - typically your dust extraction (shop-vac) or other things with electric motors and see if the problem still occurs. That might show you the source of the EMI and then many of Will’s list can be applied.

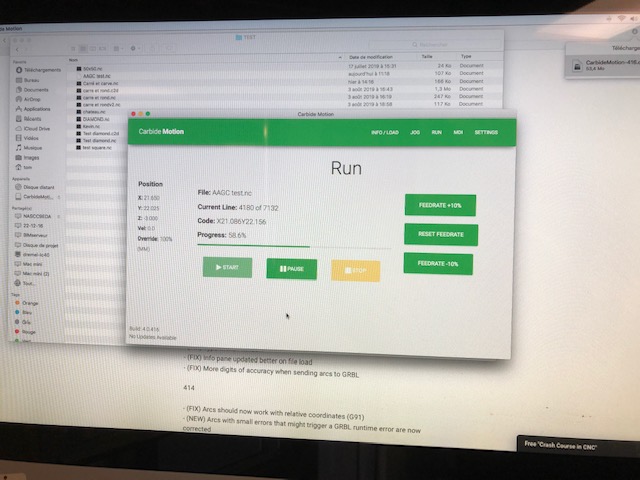

i don’t have any error now but went i start the cnc it stop at 1% and nothing not even a error. I use a file that was working before.

What i did

1- change my usb cable for a 3 feet best quality

2- i put a surge protector for all the equipment

3- i replace my laptop by a computer

3- put the file on the computer

Is it maybe my shapeoko xxl electronic board that have a problem

Do you have a dust boot? If you do, you should ground the tube using a copper wire along the length of the tube, ideally inside or taped to the outside, connect the wire to the metal part of the Z axis using something like a wire with alligator clips then ground the frame of the Shapeoko to the nearest ground or water pipe.

If you have this problem arise after a successful period of machine usage it’s almost always worn carbon brushes in the trim router — inspect them per your owner’s manual and if need be, replace them.

You can test that by running an “air cut”, with no stock loaded and the router off.

You can test/verify a file by putting the machine into check mode by sending

$C

to it at the MDI.

I will try grounding the dust boot but concerning the router i have a HDZ

@AAGC, can you please tell me about those holding arms for the dust shoe, are those custom ?

we 3d print new dust boot adaptor to fit with the spindle 2.5Kw

Yeah this is exactly why I am asking, I just installed a 2.2kW spindle, and cannot mount my Suckit for mount. Would you be willing to share the 3D files for these ? No problem if you don’t want to.

ok let do a statement. I did air print with the spindle off and the result the cnc didn’t stop. So what is the best think to do with this. I try to plug the spindle in another circuit and the cnc stop very strange. Is it because the wire is too close to the controller.

Julien i will find the file the are at the office, i will check it out monday

Thank you !

About your problem, did you check whether your spindle has the ground connected internally ? Many chinese spindles do not (pin 4 on the aviation plug), and this is a likely cause of EMI issues due to static buildup. Try grounding the body of your spindle, even with a quick and dirty hack, to see if the problem disappears.