WillAdams

January 7, 2022, 12:04pm

2

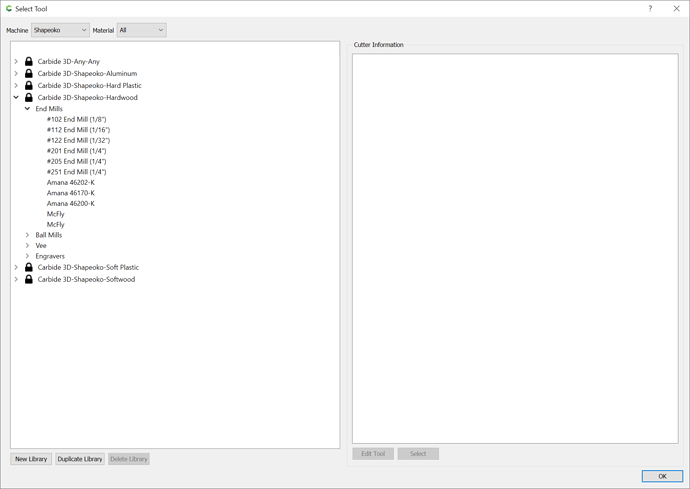

Just use the numbers in Carbide Create to start:

After you’ve got a feel for how the machine sounds and works when cutting you can increase feed and speed (proportionally, so as to maintain chipload) and depth of cut.

Extensive discussion at:

I’ve been going back to the basics of the whole feeds and speeds thing for a minute, and this time I want to focus on chipload values only, not the infinite number of associated RPM/feed combinations.

I collected a small sample of feeds and speeds below from:

usual recommand values from 3 or 4 different web sites

what CarbideCreate uses

the Shapeoko feeds and speeds chart for the #201, 1/4" endmills

Will’s [Tableau]

(https://public.tableau.com/profile/willadams#!/vizhome/Carbide3DCNCFeedsand…

and

with a spreadsheet for this at: