Right,

I thought it was worth fixing a few things now that I better understand how you want do the expensive ebony stock so I went back and edited the main sketch in the Wedge Stock component. You’re right that Fusion doesn’t capture history within a sketch but the sketch can be edited and Fusion will try to stitch the history back together afterwards.

One thing that really helped me to understand what was going on when I edited sketches and broke stuff was when I saw an explanation of how Fusion stores the models which went something like this.

There is no model of your thing in the F3D file, it’s not like an STL which contains an object. Instead Fusion stores a list of instructions (the history bar) which, when followed in sequence, allow it to construct the thing(s) you told it how to build. History is built up of atomic actions such as Extrude or Split Body, sketches are stored as complete elements.

One consequence of this is that if you go and delete from a sketch a line that was used as a selection for an extrude later in the history, Fusion throws a warning and says “broken reference, using cached things” because it can’t follow the instructions start to end any more.

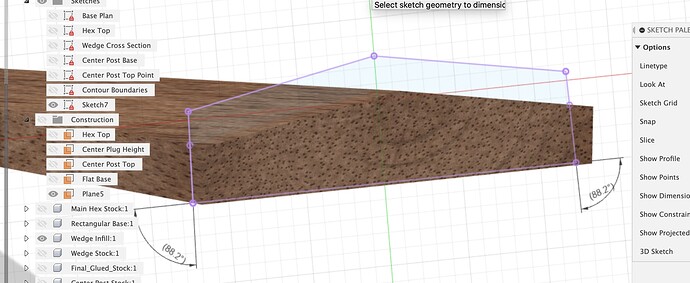

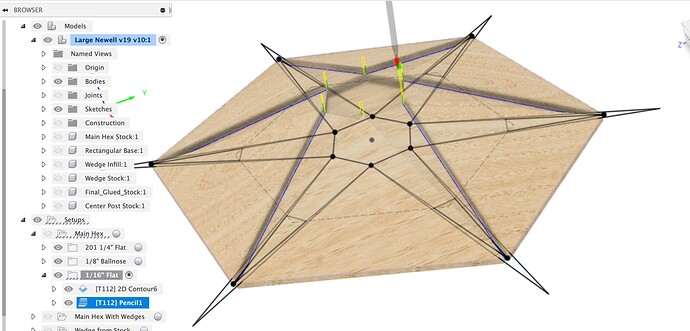

But back to your model, into the sketch in Wedge Stock.

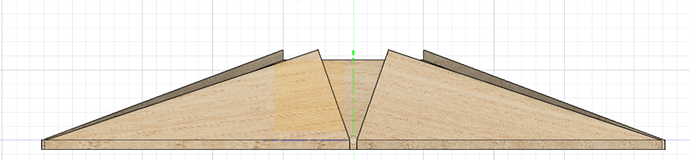

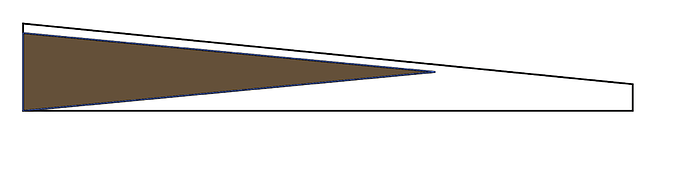

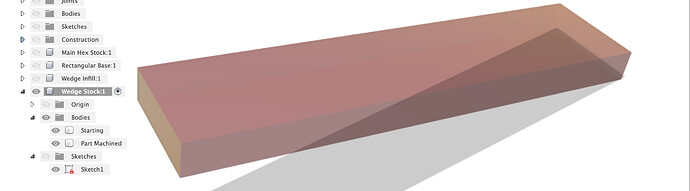

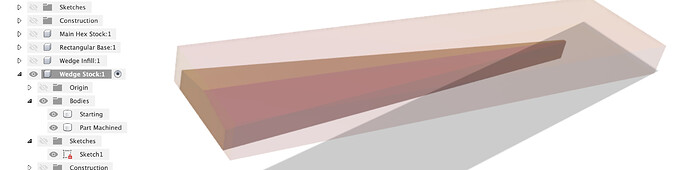

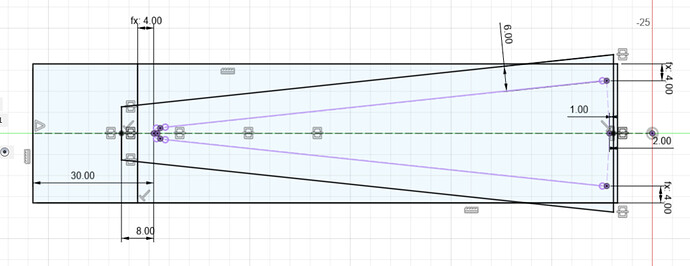

First I deleted everything and re-projected the outlines of the wedge piece, then I drew a square box around it to better represent all the extra stock you don’t want to chop up and the square lower left corner you indicated. Now we can work to minimise the amount of non-wedge stock we turn to dust. I set the sides Wedge_Stock_Flat_Extra away from the widest corners, the back 2mm from the rear face (might not be enough? up to you) and the front well away from the nose of the wedge.

I then updated the extrude to have this full square shape

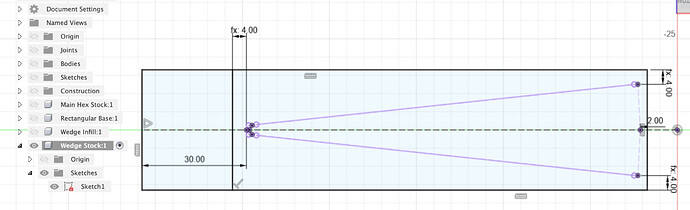

Next up, chop the long nose off the wedge blank to minimise the stick-out from the hex and how much expensive stock we chop up. Single line across the front at Wedge_Stock_Flat_Extra.

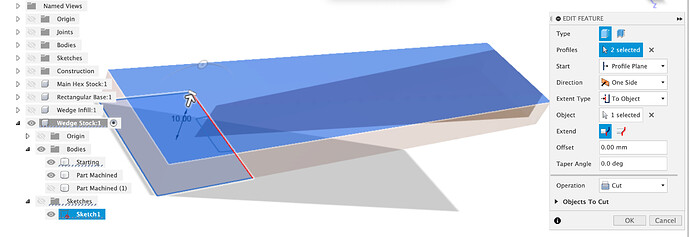

Which is then extruded in Cut mode through the Part Machined body

We’ve now got the bigger stock and all the ops as before to trim down the part-machined body.

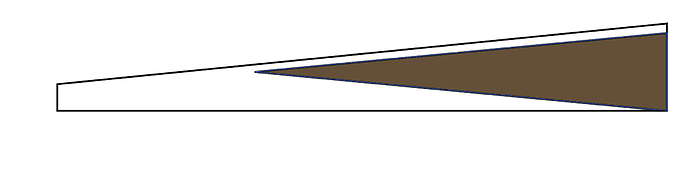

The remaining work in the sketch is to set up some boundaries to contain our toolpaths with. I drew two verticals from the mid-line and a parallel side to the wedge, that’s set 6mm away which is about right for the cutter size we’re using.

I only drew half of it because I’m lazy and like to mirror things instead of drawing them.

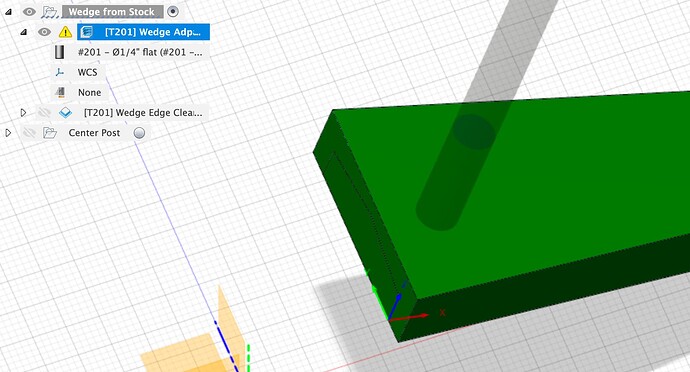

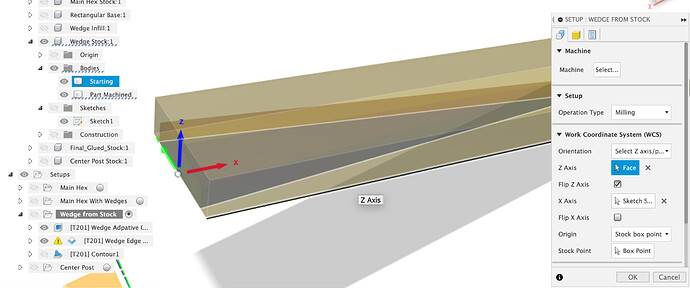

CAM setup using starting and part-machined bodies as the stock and body, I put the zero point in the middle of the back vertical face of the stock. I wouldn’t bother with the bitzero for this, I’d just draw a line on the stock in the middle of the wedge, stick a V bit or 1/8" cutter in the machine and line up on that in X, Y by jogging, zero them both and then use the bitzero to set the Z zero off the spoilboard or jig base. Do whatever works for you though.

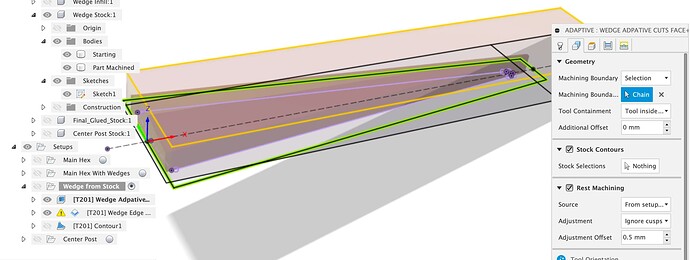

Now the adaptive clear, we will use the trapezoid we drew in the sketch as a machining boundary with “Tool inside boundary” (which is why I left 6mm)

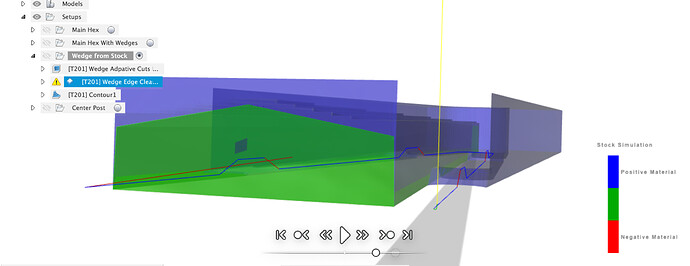

That gives us the adaptive clear constrained to what we want to cut

This is the bit where I get to go back to school and get a D in maths for being a dunce, I thought this was “interesting” and forgot why.

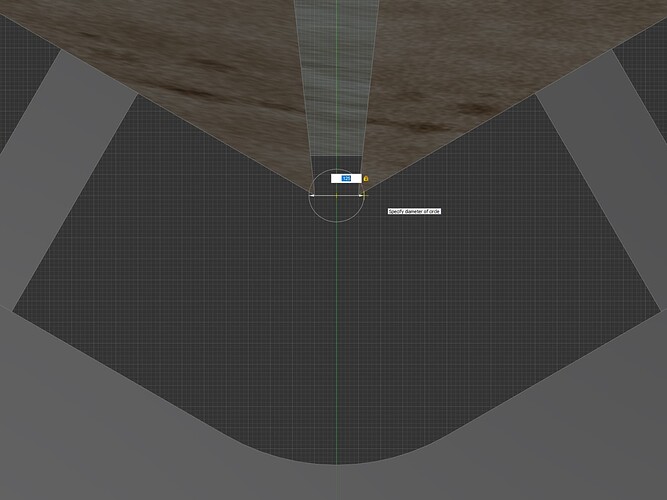

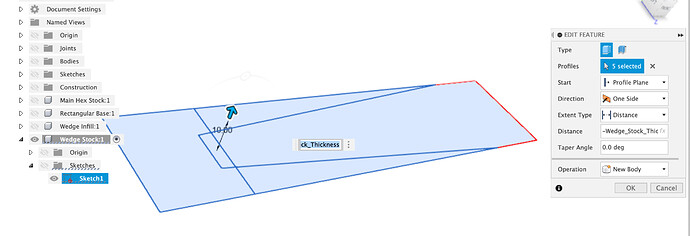

Creating a plane normal to the base of the wedge (which is how the cutter sees the workpiece) and then doing a project - intersect of the wedge or wedge part machined stock into this sketch -

We can then ask Fusion what the angle between the base of the wedge and the ‘vertical’ side walls is and discover that we are 1.8 degrees off vertical.

This makes sense when you realise that the walls are ‘vertical’ on the base hex but that for any line up the side of the wedge, normal to it’s base which is the sloped side of the main hex, that line is moving outward from center as well as up the slot walls cut in the base hex, so the sides slope in. I realised this when I got negative material warnings in the CAM simulation (always run the simulation).

This gives us two options, neither of which is perfect, but you could make both WillAdams and I happy by breaking out a hand plane to finish the wedge sides

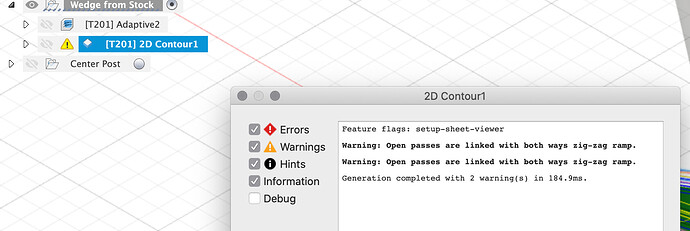

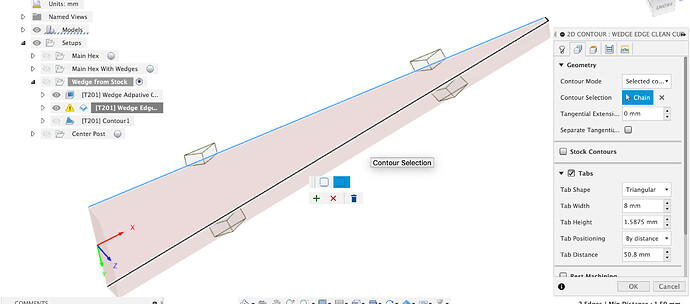

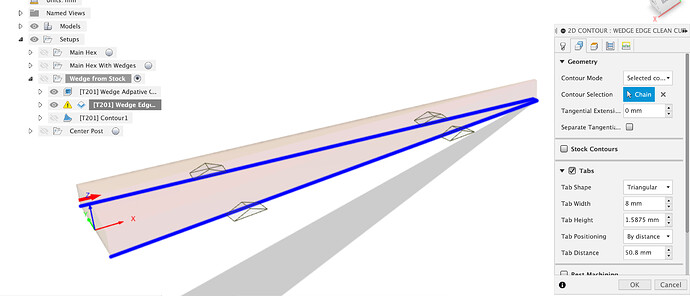

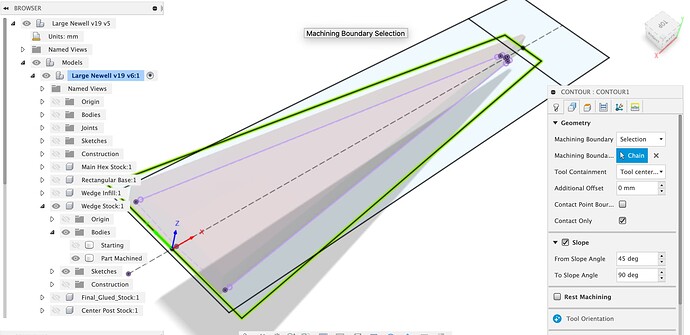

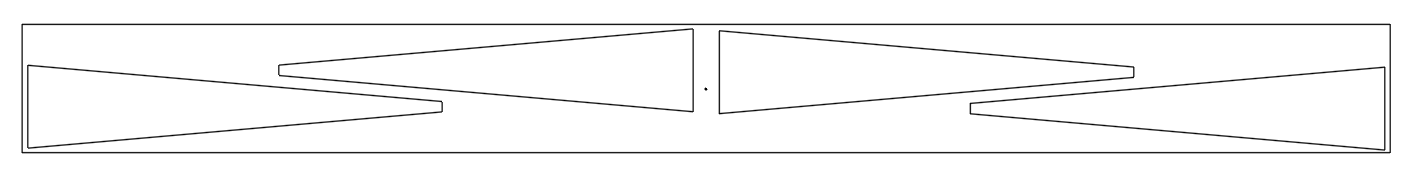

First we can use the 2D contour, select an “open contour” along the bottom of the wedge, on the three sides we actually want to machine.

Select the contour of the base, click again on the contour, select “open”, click a second edge, click + to accept.

Now we have an open contour running around the 3 sides we want to cut, yes we get a both ways warning in the CAM, meh.

Problem is that this cuts at 90 degrees to the Z plane because your router bit is straight. There is un-removed stock after this contour toolpath.

Option 0 - try it in the slot, see that the top binds in tight anyway, say you don’t care and the glue will fill the gap anyway and forget we ever saw this

Option 1 - break out the hand plane and give the sides of the wedge a slight dovetail to sit in the slot on the hex

Option 2 - for the OCD amongst us, cut the sides closer to the angle we actually need on the CNC

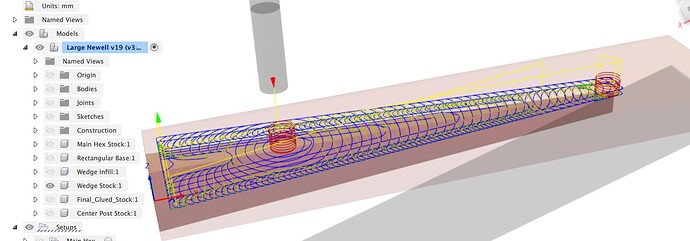

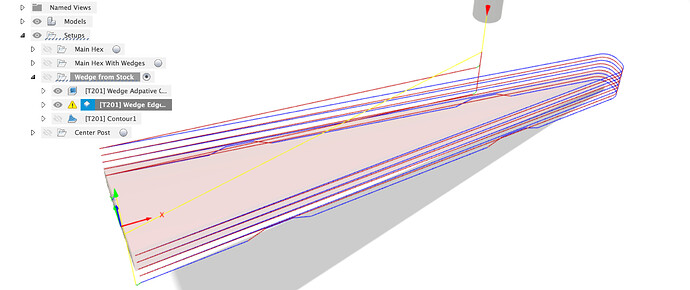

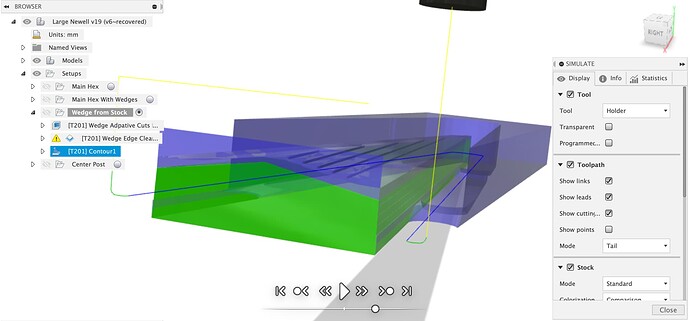

For option 2 we can use the 3D contour toolpath with the toolpath constraint we used in the adaptive clear to keep it to the sides we want cut, note I’ve also constrained the angle range to keep it off the wedge top

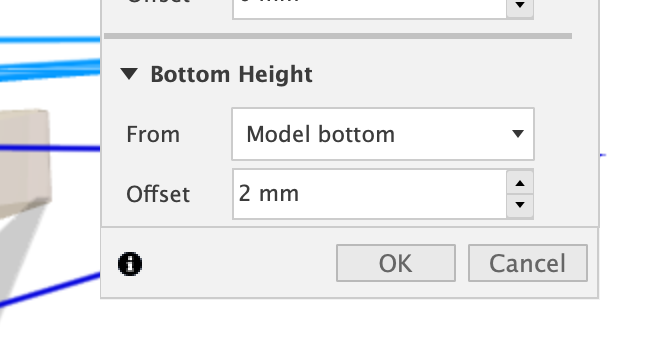

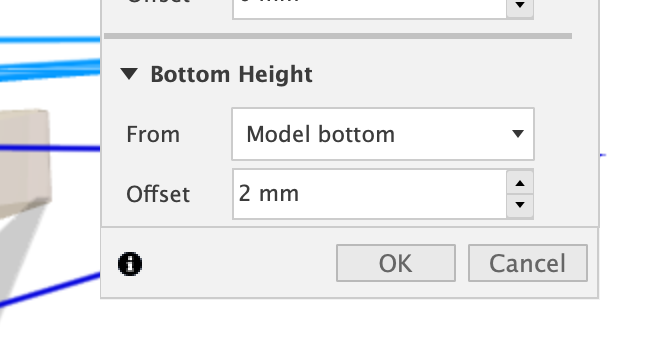

If we keep it 2mm above the model bottom

Then we even get to keep the tabs from the contour (the 3D contour doesn’t seem to do tabs)

That walks down the walls giving the slight taper (assuming we’re above the min step resolution of the machine which I think we are)

Updated Fusion file

Large Newell v19 v7.f3d.zip (1.7 MB)

I still don’t know why your toolpath chopped the top of the main hex.