I have made several flags and they have turned out nice. All of sudden the union is being cut to close to the edge of the stock. I have not really changed anything and getting good zero. The stars on the top of the union are cutting off the top of the stock. Not sure what is going on. When I look at a simulation of the project - everything looks great. Anyone with suggestions, I would be grateful.

What machine are you using. If a belt machine power off and move the gantry side to side and back and forth slowly to see if you have any mechanical problems. Solve any hard spots before moving on. Moving the gantry too fast causes the stepper motor to have EMF and sounds like the belt slipping.

If a ball screw machine check all your nuts and bolts on the ends of the ball screws.

For all machine types make sure you are not dragging the dust collection hose against something and that you are not hitting any clamps. If you use clamps recommend you use painters tape and super glue to hold down your project.

I had a 2x4 contest and cut a flag. I used the cam clamps and a long L bracket to hold it securely in place.

On the other side I put a regular flag and use rub and buff paint to color the outside gold.

Sounds like you are losing steps and that is why the carving is moving around.

New Shapeoko 5 pro. It has been cutting them flawlessly. Simulation looks great. It makes absolutely no sense to me. Everything seems tight and appears to be functioning correctly.

Double check the physical dimensions of the stock and the stock size in carbide create. What are you using for stock? Pictures?

Same stock each time.

Simulation

Dimensions look correct. Again this has been working and then all of a sudden it has changed for some reason. Probably something I have done but I can’t seem to figure it out.

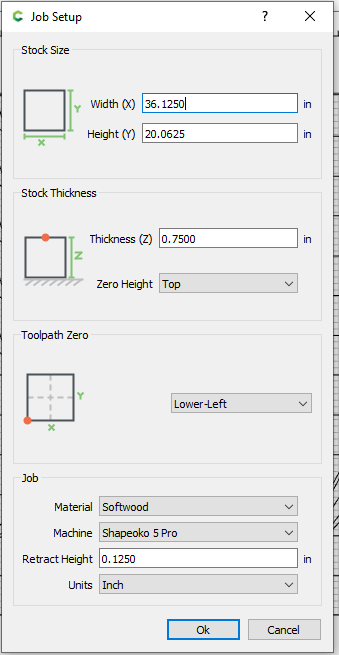

Measurement on the stock are 36 1/8 X 20 1/16.

Set the stock in the same location each time and zero everything on each Flag.

Job Setup screen shot

[

¾ Pine for stock.

Thanks for your help.

Are you resetting your XY with each piece? If not, has your Y position shifted somehow?

Rapid to current XY and see if it looks right.

Reset Zero All each time.

Got a pic of the result?

Does not make any sense to me. Running a new job now. Started with only the top most left star of the union so that I could stop it if it looked wrong. Damn thing seems to be running right now. We will see how this one turns out. $24 bucks a pop, lol. Have no idea what happened. We will see how this one turns out.

Really just looks like your stock is short. Can you measure again?

Brother, I promise I measured twice (5 times). It could have been, but to have two that messed up back to back was an oddity to me. Perhaps your right, I surely hope so. As I am cranking these things out and a screw up is $24 buck out of my pocket.

Maybe it was the Bourbon.

Is this a belt-drive machine?

Have you calibrated for belt stretch?

…

If calibration isn’t a concern, then try this:

- secure a piece of MDF larger than the stock and machine a pocket the size of the stock, then see how the stock fits into that

Post a photo showing the stock and stock dimensions and what the pocket measures to, and the .c2d files for the pocket and the original.

This topic was automatically closed after 30 days. New replies are no longer allowed.