The working area includes the distance the machine is able to move forward off the spoilboard so as to be able to interact w/ the BitSetter, see:

for some discussion on this.

It looks like you were trying to take more off than the endmill which you used could comfortably remove in a single pass — best way to do this is to start cutting at the highest point, removing only as much as is necessary to allow the endmill to cut reliably, and to increase the depth by that amount for each pass until one surfaces the entire area.

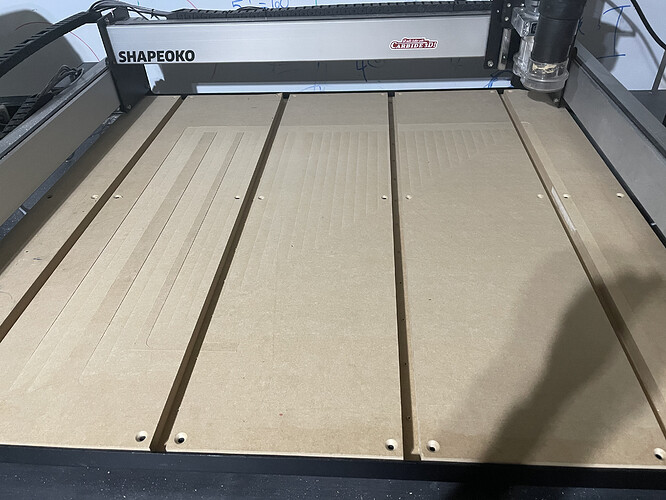

Attached is a doc I prepared about spoil board considerations. See if it is of any help.

spoilboard_considerations.pdf (1.3 MB)

All though you have a different type of spoil board than I wrote about it is still applicable. What ever bit you are using try using less then 50% step over.

Thank you for the response

Thank you I’ll go back and look at what my settings were I appreciate and will read your steps to see if I can fix this

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.