Isn’t this backwards?

Yes, that was backwards, a mistype. My bad. Fixed in the original posting.

Would it be ethical/legal to just exhaust it outside, without any separation or filtering?

No.

Scrimping on filtration would be “penny wise and pound foolish” IMO

Very much so.

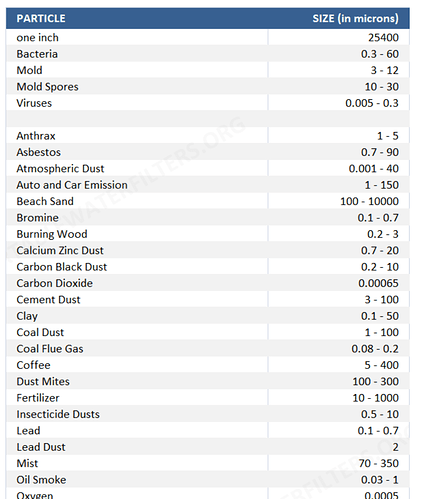

As I’ve pointed, here and elsewhere, if the air (from the vacuum for particle collection) exhausts back into the room where people are, a HEPA filter is called for. The best one can afford; 0.3 microns is the standard.

Can the air be dumped outside, avoiding HEPA filters? Yes… but there are still gotchas.

One still needs a dust separator, so as to dramatically reduce the amount of particles dumped outside. This removes well over 90% of the particles and concentrates then in the dust separator, making for easy disposal. Remember that these particles are NASTY to your health.

In general, it’s a good idea to use a respirator whenever one empties their dust separator. This should be done OUTSIDE well away from a residence, when standing up wind. The 3M 5000 respirators with a HEPA filter is a good choice.

So now the air is being dumped outside. It still have some NASTIES in it. One must prevent the air from easily returning to the work area and from entering other places in a residence (where people are). It makes no sense to exhaust it from your basement, only to have enter your house from the open window near the exhaust port.

Now one should have a 5 micron filter to prevent the accumulation of “snow”. These are inexpensive cloth bags. One would have this outside the exhaust port, covered to prevent getting wet from rain.

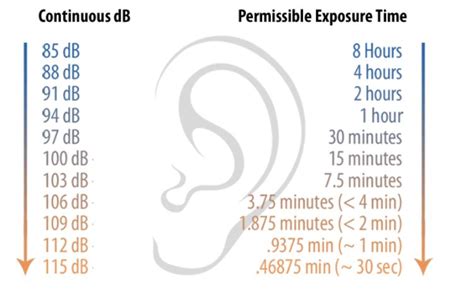

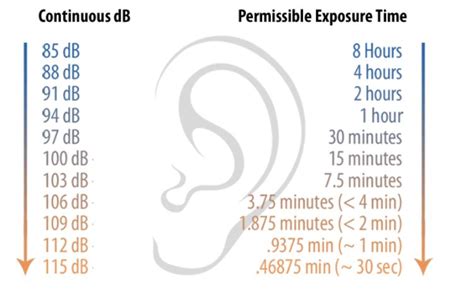

Finally, one has to deal with NOISE. Vacuum systems are noisy and the exhaust port will really upset a close neighbor. It’s best to exhaust far from others (due to noise), or at least pointed away from others. Yes, it is possible with a little bit or care to build the little structure over the 5 micron cloth bag to act as a muffler. Just remember that the source being emitted here can continue to HOURS. Be sensitive about your neighbors!

Yep, but cyclones and HEPA filters cause drops in static pressure (suction).

Correct. This can easily be addressed with properly addressing by adjusting the “strength” of the dust collector and using proper tubing techniques.

This new dust collector would help with that because it has far more static pressure than most dust collectors with more than adequate air flow for most/all hobbyist uses.

This is really cool! I hadn’t seen that one yet. It’s also way outside the cost range of most of the people on these forums. There is also the issue of NOISE. These devices, if inside with people, make a real racket. Proper design calls for a small room or enclosure, with sound suppression materials, if necessary, to not exceed the safe levels of sustained noise requirements.

Yes, long term sound, even at modest volumes, can be detrimental. CNC machine are near perfect generators of sound that can drastically and negatively affect ones health and well being.

I regularly have jobs running for as long as 12 hours. The 85 dBA level is easily generated by most CNC machines. The Nomad, with its enclosure, keeps the sound levels quite well. Even so, my Nomad enclosure pushed for even lower levels, because the sound can be irritating.

As pointed out here, folks shouldn’t rely on just the dust collector because it won’t collect all of the dust and they’ll need protection when emptying the collected dust.

Bill is considered a bit of an extremist I’m afraid. He clearly states that he has allergy issues which would hyper sensitive him. I trained in Physics and have gone through the math. I don’t, in general, disagree with him, however, few in these forums can afford the level of safety he is advocating. This is all about risk reduction, the better the protection the better… but the reality of budget must enter into the equation.

What he doesn’t state, is how well something a bit less “fancy”- and much less costly - does. Which is remarkably close to the level he is asking for.

I’m available to discuss how to achieve very good levels of safety, but be aware that the requirements, have some stiff costs associated with them.

A practical tradeoff, extremely effective, is to build an enclosure, and let the vacuum run for a few minutes after the job completes. Lining the enclosure with sound suppression materials really helps, especially for larger machines and longer running jobs. Having a spindle, over a router, also helps as spindle as inherently quieter than routers.

A HEPA respirator would be a wise investment (if you can find one these days!)

For sure!

Yes, they have become hard to find, ironically due to COVID, since a HEPA filter will not stop the virus, which is some 10X smaller than the filter. If people do want them, please let me know. I can point to industry sources where they are much more likely to be available.

As I pointed out, one should use them to emptying their dust separator.

As a general solution for being around CNC machines, they fail pretty badly:

-

Wearing them (which I have done) for extended periods of time is very hot and uncomfortable.

-

The particles get into your clothes. If one doesn’t change after being around the CNC

machine, they bring “second hand” particles home. Not good. Even learning how to

handle particle contaminated clothes takes some doing and discipline.

In the US, asbestos requires special disposal procedures. Is that true of fiberglass dust too?

Yes. This gets into wearing “Tyvek space suits” and respirators. This isn’t practical for CNC machine use.

As I’ve said, ANYTHING IS BETTER THAN NOTHING, this is about risk management. The more one can do, the better. When I design for commercial customers, a nearly universal complaint is… THIS IS BLOWING OUR BUDGET! It sure is… because the CNC companies don’t make it clear how dangerous things are with respect to air and noise safety.

Besides the dust collector and dust separator, there are tubing requirements. Routing, dust explosion prevention, cleaning and safe cleaning… the list goes on.

Few in this forum are going to run the minimum tubing necessary to achieve near perfection (4 or 5 inch tubing, very powerful blowers with very high air velocity and pressure capabilities, near optimal routing, etc.).

Machining friable materials (e.g. FR4, Garolite, Carbon Composite, MDF, woods, etc.) generate particle problems very different than the safe cleanup requirements for a building. even plaster and spackling dust is nor understood to be dangerous.

mark