Oh wow, nice spot Rob. Gotta see this spindle cut some decent chips now it is diagnosed. Awaiting new vid with metal flying and mirror finish…

Sick, glad it was something simple. Do yourself a favor as a new machinist and watch this video from nyccnc @Vince.Fab made. https://youtu.be/b8CndwnfoCM . Please do not get caught up in every little technical detail and just enjoy cutting. If your machine is making angry noises and not sounding smooth it probably isnt happy. Most if not ALL pre done feed and speed programs assume your using a vmc not a small desktop mill so the feeds and speeds almost never translate over well. It is very easy as someone who chases numbers to get stuck in a black hole and it can suck the fun out of making things. Also Welcome to the club of custom nomad 3s! Vince has one (older nomad 883 iirc) and I also have one. Now you have one. This here is mine Bromad - The nomad 3 dewalt dwp611 conversion project

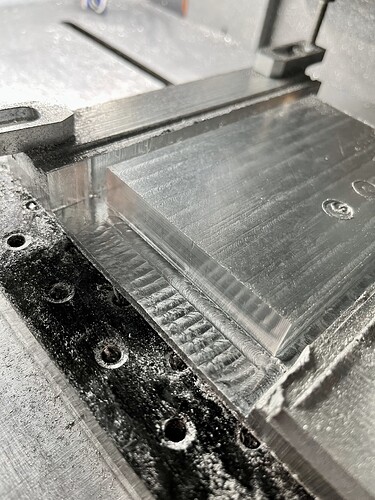

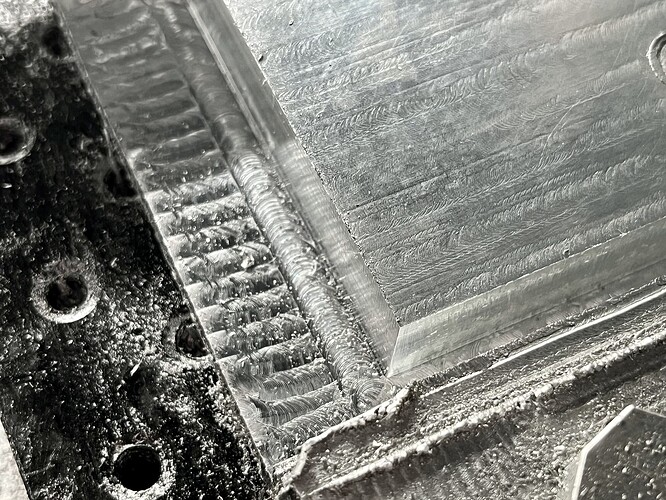

Started with a pretty conservative cut since I didn’t know how it would perform at all going the correct direction ![]() This is 60% WOC, 0.6mm DOC, 8.4k RPM and 0.003" chip load.

This is 60% WOC, 0.6mm DOC, 8.4k RPM and 0.003" chip load.

It cuts, isn’t vibrating my entire apartment, and actually isn’t that loud! There’s chatter, but waaaaaay less. Used 150% feed override after this and its still cutting fine.

Thank you! That video was super helpful! Millyzer looks super useful def going to buy that. I think just a bit of tweaking to minimize the chatter is all it really needs, then im guessing it’ll be pretty fine with most cuts.

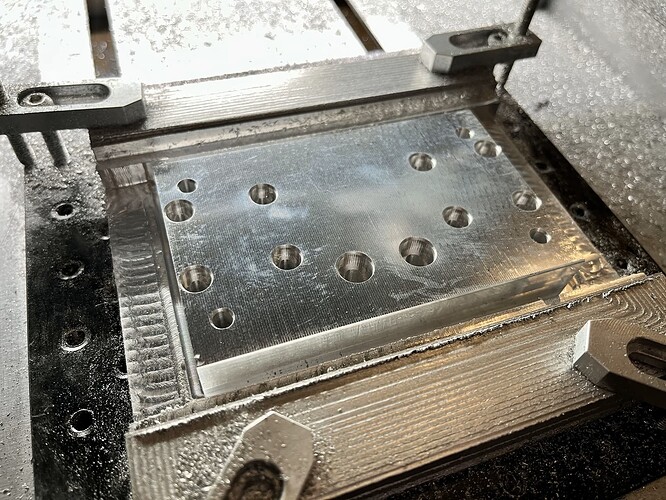

Finally finished up clearing out the sides and did a contour cut. Not too bad looking for roughing job.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.