Randy

August 25, 2025, 3:25pm

5

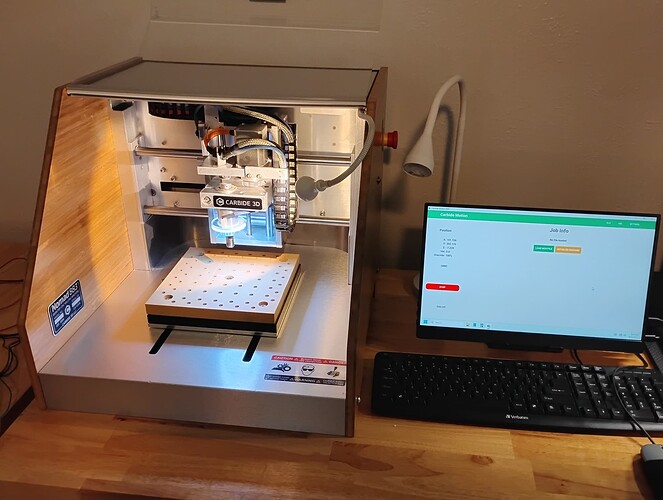

And here is the Classic+. I forgot until I unpacked the machine, that I had made a “hybrid table” of sorts by putting clearance holes in an MDF wasteboard to allow access to the threaded table’s holes underneath.

Here are a few relevant threads

My Nomad developed a “clicking” noise over the past couple of weeks (before a 2+ week teardown…) It turned out to be in the spindle.

On the Nomad, the spindle chuck is pre-loaded into the bearings through a couple of Belleville springs. The only thing holding the preload is the two setscrews in the driven pulley from the spindle motor.

Setscrews really aren’t a reliable method of withstanding thrust loads–they are fine for transmitting the torque from the spindle motor but that is an order o…

Something I’ve been thinking about for a while has been upgrading the X and Y drive belts from 6mm to 9mm width. This would increase the stiffness of the axes against cutting forces, without actually increasing the sideload on the motor spindles. This has already been done on the Shapeoko forum http://www.shapeoko.com/forum/viewtopic.php?f=7&t=4266

Since I had the machine all disassembled for the spindle rebuild I figured the time was right…

I ordered pulleys and belts from B&B Manufacturing…

I’m going in a slightly different direction (but aren’t I always…? http://www.ebay.com/itm/252016192332 which were $4.20 including shipping for two of the 50mm size.

[image]

The first job on the Nomad after the recent teardown and rework (more about that later) will be to make a housing that fits on the spindle cartridge. I plan to make it an interference fit, probably using an o-ring. Here is the ring temporarily powered from the 12V system fan he…

This probably doesn’t have any bearing, but I am machining some model railroad rail components from 1mm nickel silver sheet using a 2 flute .50mm diameter square-end mill. 2ipm speed and .005" depth of cut, slotting (i.e. full width cut).

Scratch-built small-scale model railroad track is often constructed using nickel-silver rail soldered to crossties cut from single-sided PCB. Since the electricity for the locomotive motor is transmitted through the rails, the PCB foil needs to have an “isolation gap” cut between the rails.

I have machined some turnout (switch) bases from a sheet of 1/16" (1.6mm) paper-phenolic PCB.

First I cut the iolation gaps wtih a drill-pointed endmill from Melin, filled with gel superglue, and scraped a…

Which is all ancient history by now…not one, but two generations of Nomad since it…

5 Likes