rules:

-Make a dust shoes.

-Take a real « portrait » of it, the picture have to square only your dust shoes.

-Post your portrait.

It could be fun to have just a big gallery that collect only the picture of our dust shoes, isn’t it ?

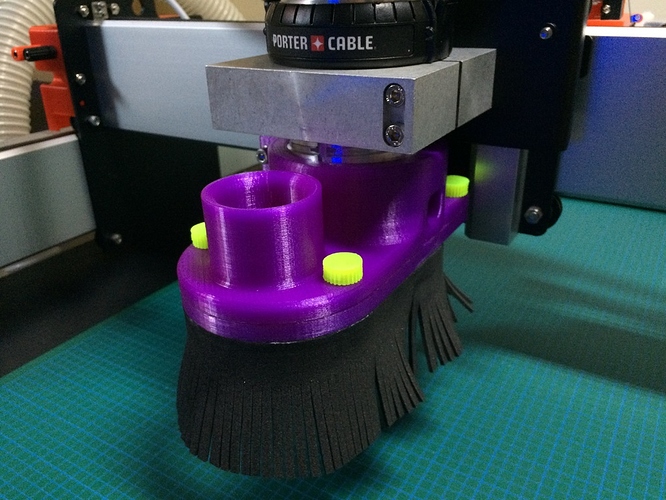

Here is my oldie 3D printed dust shoe.

I never got a chance to actually mill it, as it would require 2 sides milling and my skills are not up to that level yet. I got all the HDPE for it, but it will be a project down the road, eventually

Source can be found at : thingiverse

For the Nomad Classic. Has a camera to let me see inside. Very happy with it.

Such a tease… show us the camera view. That is a great idea!

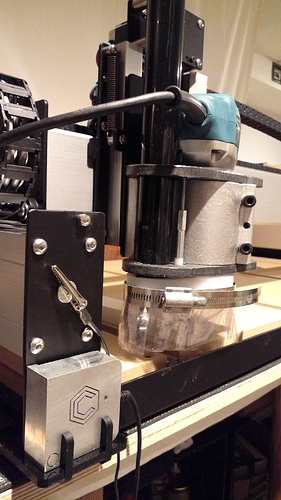

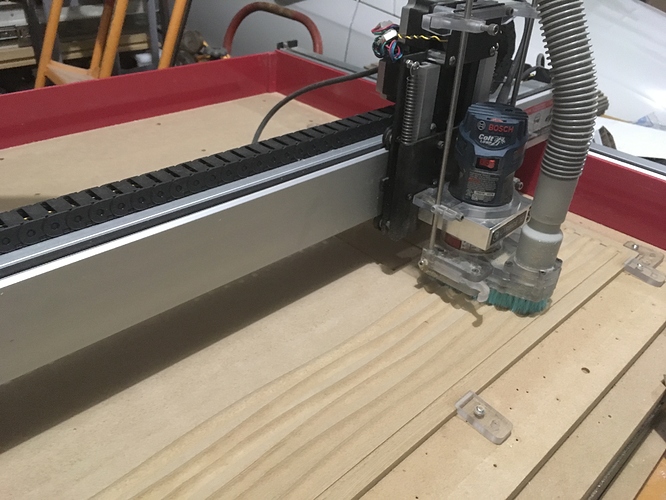

Okay, here’s mine, along with the holder I made for the Carbide 3D corner finder/Probe:

Files for it ought to be on the wiki somewhere — the router mount is a 65mm unit off eBay — one of these days I’ll switch to the new Z-axis plate (when I’m feeling industrious enough to drill and countersink 4 holes again, but I need to replace my countersink bit first).

Here is a link to a post I did on my dust shoe a little while ago:

That is a fancy DW611 you got there

That would be a great pick up line at a bar next to Makerfaire!

Dan

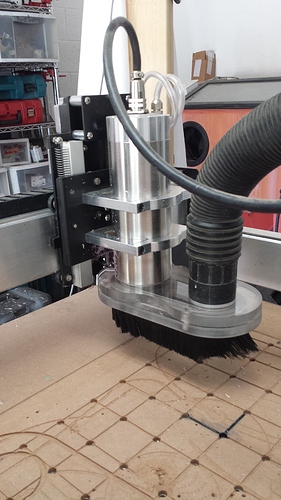

Here’s my dust shoe version. It is entirely made in polycarbonate on my Shapeoko.

The advantages of my design:

- It does not compromise X axis travel

- It is easily removable (2 set screws)

- The front part is a “clip on” (no screws)

- It can stay at a constant Z or it can travel along with the spindle

- While surfacing the MDF table or cutting MDF no dust escapes.

That is real nice work, Bola.

Looks great! Might have to borrow some inspiration from you.

Any issues from the smaller diameter hoses? I tend to see most builds using 2" diameter, and I’ve had cases where some wood comes off along the grain in long strips.

I had no issues so far with this hose. It’s connected to a Ridgid vacuuum which has plenty of power. I don’t cut real wood, only MDF, plastic and aluminum, so no issues with those.

Today I finished my new model of dust shoe, which is way more compact and fits like a glove on my brand-new updated spindle. I will take some pictures tomorrow.

I really like this one! Would you be willing to share your files? I am waiting for my new XXL to arrive now!

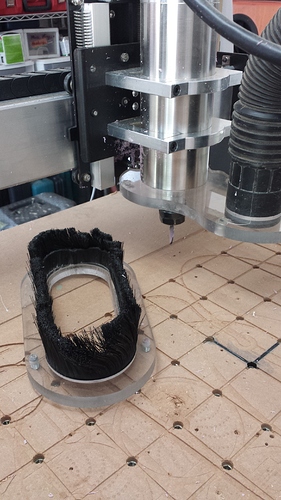

Here is ours.

It is very much based on the one sold at http://www.ev-guide.com/3d-printing-products/shapeoko3vacuum . We bought from them, but it broke (they will be sending a replacement). While the replacement doesn’t get here, I had to design one so we don’t have to stop the machining. I made some changes that I didn’t like about their design (got rid of the bottom, made the attaching places longer and sturdier) and 3D printed it.

are planning on selling one?

care to share a .step and or .stl file of this?

I don’t feel like I could sell this and guarantee your total satisfaction, but I don’t mind sharing the files. I am sending you a link per private message.

This dust shoe is for 2.25" hose, and I used whatever bolts we had in the lab. You also need to get the brush, otherwise it won’t work well.

I think you can use this type of brush from McMaster: https://www.mcmaster.com/#brushes/=1cmzcdq

I also have one of the EVGuide units.

I would sure appreciate the cad file. I need to modify it for a Makita. I use F360 but a STEP file will be fine.

No worries if you don’t care to share the cad, I know it was a lot of work!

Thanks!