Just wanted to be 500th to post, to express my gratitude for this wonderful thread !

Yes, it’s inspired many to expand their capabilities!

You guys have me so excited to dip my toe into milling aluminum! Thank you for putting so much info out there for us new guys! Another fine example of why this community (and company) are so awesome!

I hope that you recycle you aluminum waste!

That’s not waste. That’s man glitter.

There is not a big market for man glitter, most wives would strongly prefer that you abstain or t least keep it to a minimum.

The chips are set aside for a recycler that comes by. Glad you guys enjoy this stuff, its been an interesting journey and the more you learn, the less you know lol.

We’re just getting started guys, so pull up a seat and pour a glass.

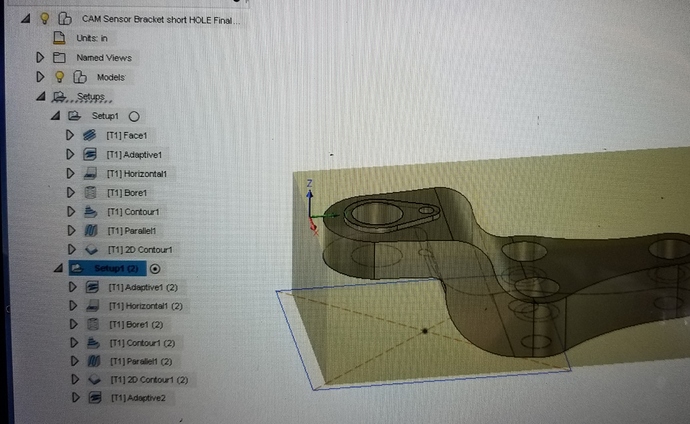

Today’s entertainment is a custom cam sensor bracket that was double side machined and no fixture flipped with floating triangular tabbage, only straight endmills were used.

Can you explain what the sensor does? Is it measuring RPMs of the gear?

Basically the engine is setup with a totally custom ECU, harness, sensor package. The sensor is paired with a matching magnet and just picks up rpm yes. The owner/tuner specifically wanted both cam and crank sensors to be able to sync so it will know if there are timing issues and a have better startup. The engine is running 17:1 compression and it bumps up almost a half point once warmed up.

Good to know. I learned a lot about auto sensors and computers recently and was curious about that.

Nice job!

Hey Vince. Such an inspiring thread! Those first parts you shared last year - were those on a standard out of the box S3, or did you upgrade anything before then? I know you made the custom through mounted vise, and added a coolant/mister setup…?

Its been a fun experience! I believe it was still stock back then and I had cut some pretty intricate stuff. Started with a cheap Amazon siphon mister, nothing special.

This piece is hot off that same machine, 2.5 years old and chugging away no problem. Tram is a teeny bit out but not bad. Double sided with floating tabs and no fixture flip

Billet 2x3x6"

Those are some nice looking parts. Deep Pockets the way you cut them out but it sure looks good.

The sensors, are they hall affect sensors? What computer system are you using to take advantage of all that engine information? You must have a way to enter the number of teeth on the sprocket, how does it know where to TDC is for the degrees? Is there a hole or something to indicate the zero degree point. Sorry for the car questions on this forum but your projects look very interesting.

700 horsepower

Miata

Dual plenum starting out with a sweet 3d machined curved contour bad mamajama

Just letting the chips fall where they may

But now the engine is not balanced anymore, since all other parts feel jealous !

I don’t know about jealously but you are absolutely correct on balance! One part of the deal was that I would be given the chance to re-fabricate the rest of the system in the future.

There are plenty of gains to be had but I’m not gonna nerd out on that stuff right now lol.

@Vince.Fab in one of the vids you posted seems like youre using Carbide 3d 1/4 single flute end mill. How do they compare to 6mm EnPoint cutters from Amazon?

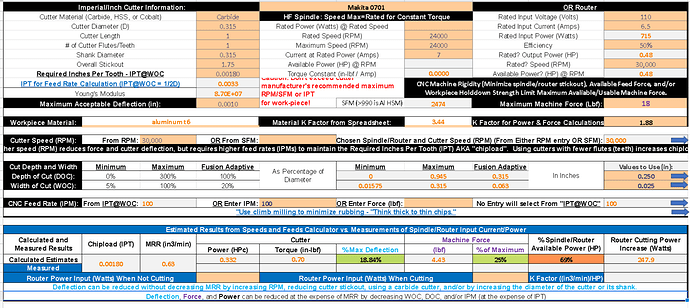

That’s actually an 8mm Datron 4-1 single flute as spec’d on the cut worksheet. Nothing comes close to their balance. The 8mm is also close to $100 but its crazy stiff at long stickouts and still can achieve high ipt.

But imo the C3D single flutes have much better performance than the cheap 6mm cutters. Mostly due to geometry and just having better chip clearances.

lol even better. Would love to try Datron’s end mills one day, but first have to figure out my machines a bit better. I’d cry for a week if I screwed $100 end mill up

Wish Carbide had their cutters fulfilled by Amazon because their shipping prices are exorbitant. I’m a tad surprised though. I’ve had very good experience with those 6mm end mills so wonder how much better Carbide’s cutter is.