My HDM gets delivered Monday and I’ve been chewing thru aluminum for some time on my Pro, I’m starting this thread to show how much better, faster or ??? The HDM is with some of our parts. I’m hoping it can be pushed like I’ve been doing on the pro and cut times down and improve quality!

Mind sharing a few of your go-to bits, feeds, and speeds for the pro? I started aluminum a few days ago. Have had some success, but also some chip welding and broken bits. I ordered stub coated bits specifically for aluminum, hoping that will help my success rate.

I’m curious to know, what’s the largest aluminum part you’ve cut on your XXL?

This far I’ve been able to double or triple my best MRR on the HDM compared to the SOPro. Being able to use 3/8" tools for grunt material removal helps a ton with the extra power. Between using larger diameter tooling and the extra rigidity, wall and floor finish is much improved.

That is awesome to hear, I have honed in on some great recipes for the Pro with a Mist Coolants setup and single flute bits. Hoping to move to some chip busters with the HDM

Here are some of my favorite recipes I start from with most of my aluminum projects with my mister. I use a recipe of WATER + ALCOHOL + CUTTING LUBRICANT without this the bits wear quickly at these speeds. With the setup I can cut a lot of material. The main purpose if quick and decent removal of material and then i go back in with finish passes.

RECIPE #1: ROUGHING MATERIAL

Single Flute 0.25" Bit - Amazon Single Flute Bit - $19

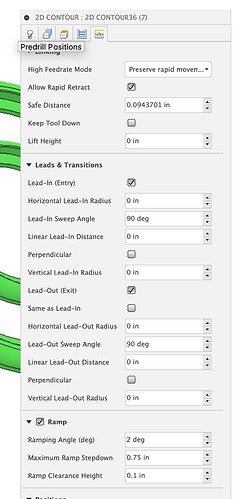

RECIPE #2: SLOTTING - The Ramp and Exit are important

Single Flute 0.25" Bit - Amazon Single Flute Bit - $19

I got my HDM this week and too much paying work to get the enclosure built. I’m hoping to get it running this next week to test. The delivery and packaging looks solid!

The welded steel base for my HMD ENCLOSURE is done today, lots of finish work, but now I can fit the machine in it and get the sides, door and all the bits setup once I move my pro XXL to her new space in the shop…

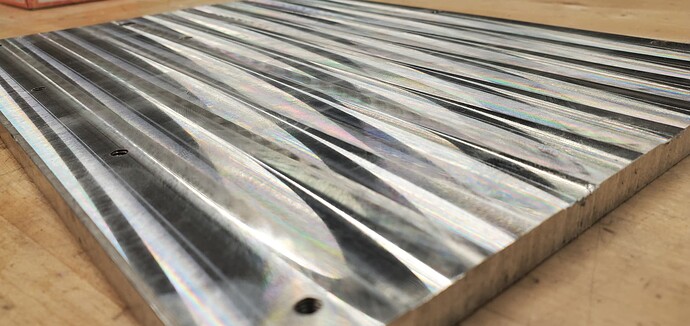

Cut these on the Pro yesterday in about 1 hour. 600 grit quick sand and polish… I’m itching to get the HDM cutting!

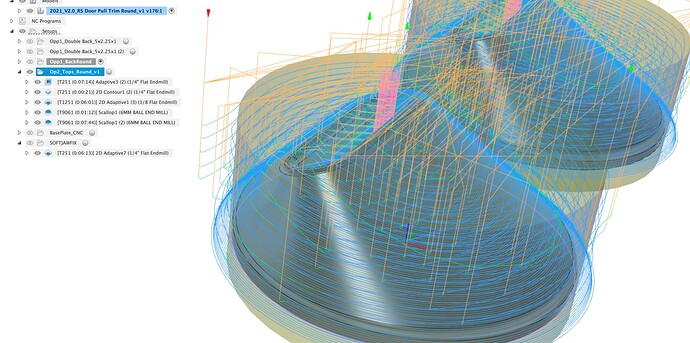

I’d love to see the tool paths and flip setup used to make those. With the hole at an angle was this a 3 setup job or did you just strait drill it and paint it black?

The hole/slot is straight thru, I put a large 2mm Chamfer on the backside so the pull strap doesn’t bind. The operations are pretty simple.

- SoftJaw in a SMW vise to hold the 2" stock and a flip plate that is flush with the top of the softjaw

- Zero is set at a center point in the second side plate, I machine M5 threaded holes in the first opp to then hold for the flip (and are used as a part install)

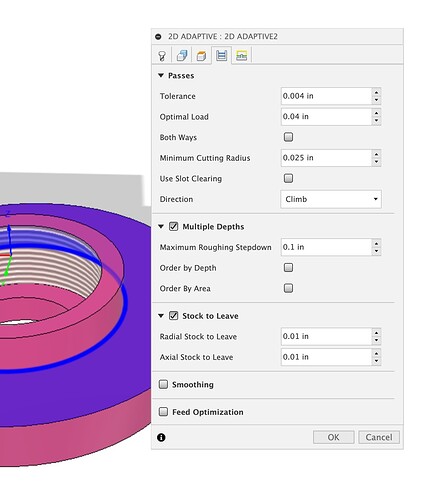

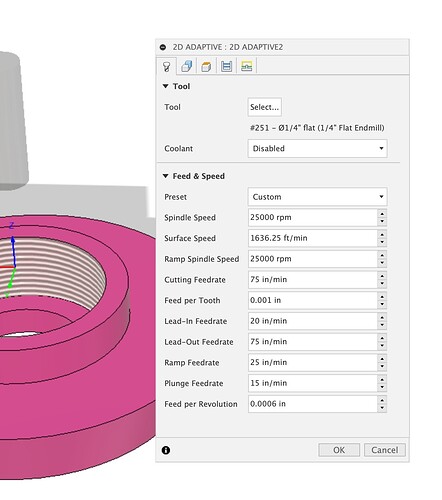

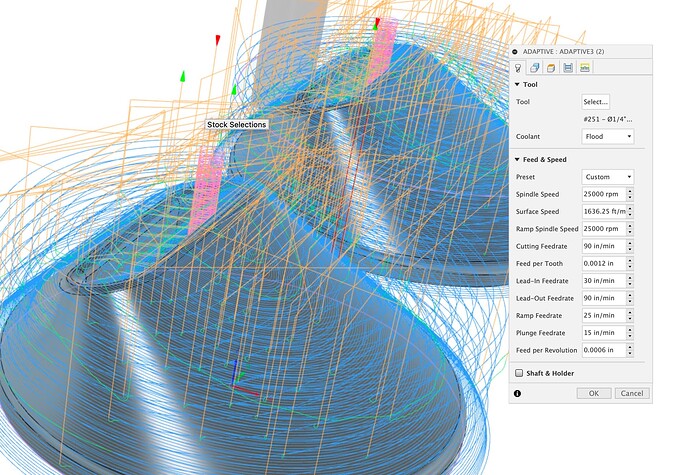

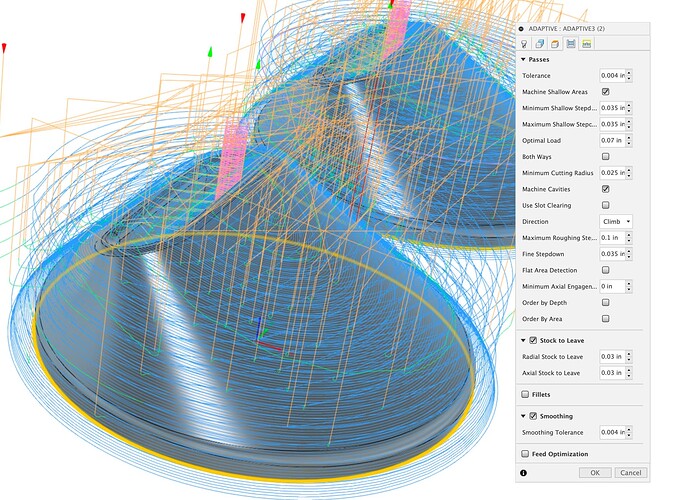

- The flip I do adaprtive rough with a .25 Endmill, then finish the slot with a .125 endmill

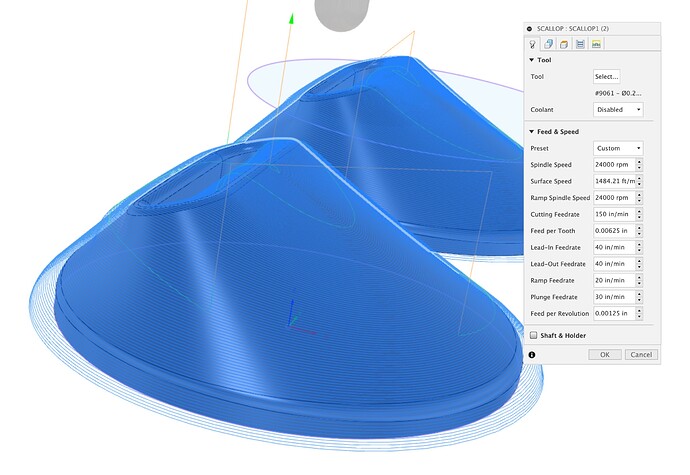

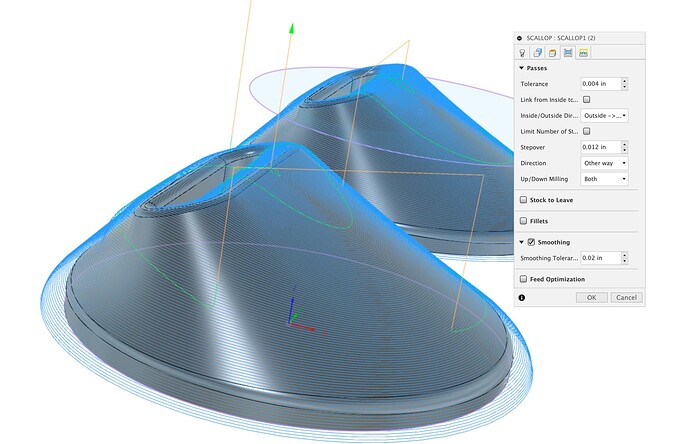

- The Finish Strategy is to use a Single Flute Ball Mill from Datron

One pass to .02 STOCK TO LEAVE at a large stepover

2nd Pass is at .012 Stepover for the finish.

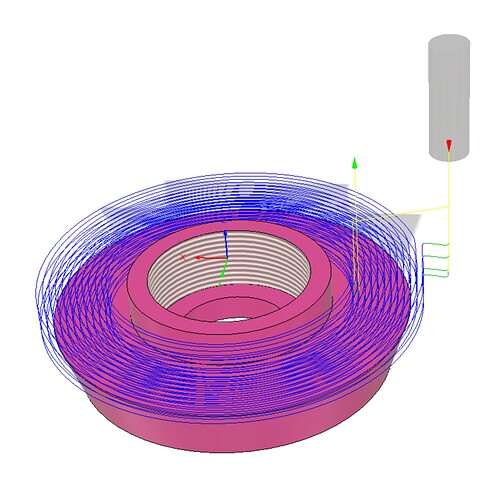

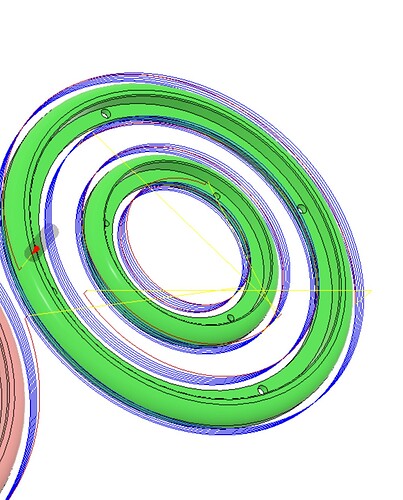

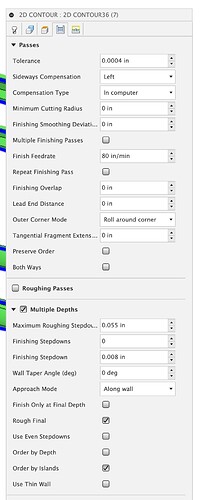

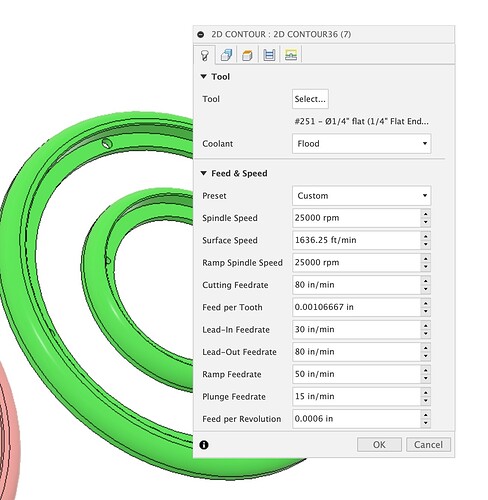

Here are some screen grabs of the Path Info:

Thank you for the cutting parameters they will help everyone looking to get similar results. I love looking at the strategy’s and feeds people use for work holding and milling different parts.

How do you like the Datron Sf ball mill? I have a Helical 2f on order because of the cost factor is half.

The Single Flute is nice, I use it for certain projects, but with the Right S&F I can get a decent finish with a .25 SPE Ball End Mill too. This complex shape made me use it so I can do a Semi-Finish and finish with the same mill

I have my HDM on the Steel base we built and we are hoping to get the enclosure done next week so we can fire it up ASAP…

I hope you don’t mind me asking this here vs starting a new thread.

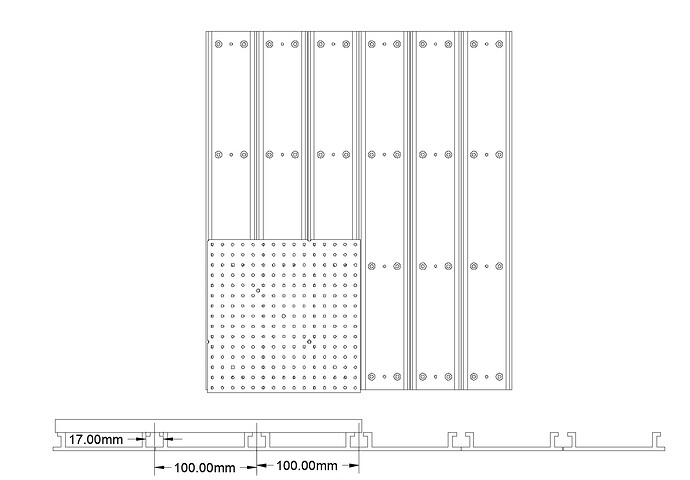

Can anyone tell me what the bolt spacing is for the hybrid table wood slats on the HDM is?

I am going to mill down some 3" x .75" 6061 bar stock to replace half of the wood bed slats so I have a coolant proof base I can drill and tap to bolt down my 1/4" SMW fixture plates from my So3 until I can rob a bank to afford the 1/2" HDM plates and mod vise from SMW.

I have to be able to roll my wheelchair under my table so a strait drop tray is not possible for me but your chip tray design makes me wonder if I could open the rear of my enclosure and make a cross draft version that uses the vacuum exhaust to blow the chips to the opening. It would probably just turn my enclosure into a snow globe though.

HDM slats v5.zip (140.1 KB)

This might help. I forget if you use F360?

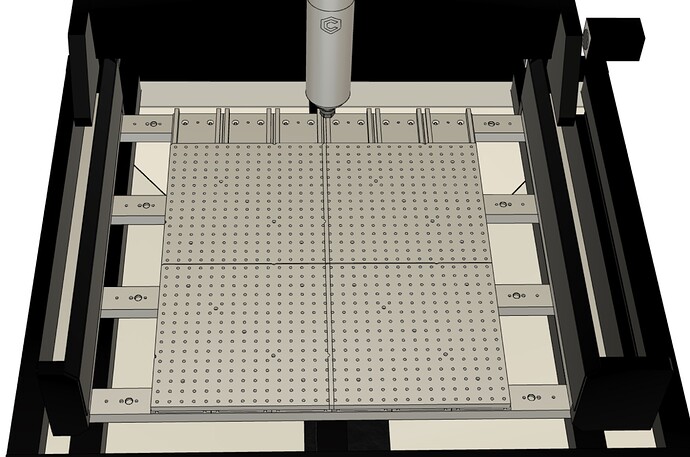

I am planning on using 4 of the original style M6 Plates on my HDM since I have some many of the SMW vises and plates, it will work great from what I have tested so far. See dimensions below.

Per your question below, I think it could work well, once I am up and cutting I plan to test how it could be modified to capture most of the chips as I refine, You can see in my mockups that my plan is to leave the side rails off the base, just the 4 center SMW plates. The plan is to have the chops fall down into the chute to capture them, the whole base is open under the HMD, so it should work well with a blast of air.