wanted to share the results of some trial and error on cutting small text into two tone HDPE.

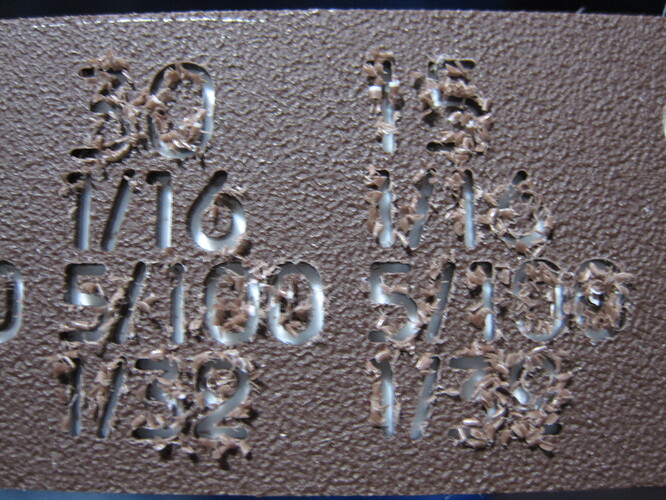

The text I wanted to cut was small, so I was using a 1/32 upcut endmill aka 122.

However the upcut left unclean edges (focus on the “15” in the upper right corner). That is the result of cutting down 1/16 of an inch with a 1/32 bit. It got into the 2nd-white layer, cutting through the 1st-brown layer. But didn’t cut the top cleanly.

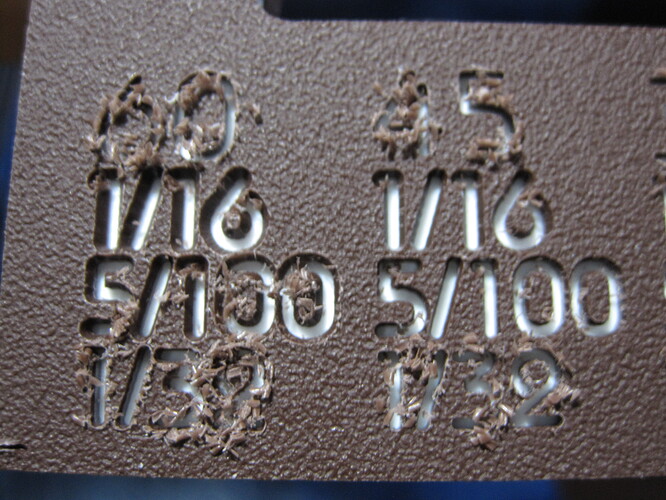

I then tried different methods of cleaning up the cut with a 2nd pass.

In the photo below, the top row “60” text is just the first pass (1/32 bit) without a 2nd pass.

The “1/16” under the “60” is using a 60 degree V bit at 1/16 depth, the 5/100 depth, then 1/32 depth.

The next column is the same test with a 45 degree V bit.

You can go back to the first image to see my attempts using a 30 degree and 15 degree V bit.

After looking at the results, and trying a brush to clean up further, the best was using a 45 degree V bit at 5/100 depth (after the initial 1/32 at 1/16 depth). But even with that result I would be having to do some manual cleaning up with a small razor blade.

So I’m going to try throwing some money at the problem and get a 1/32 downcut bit. I know my 1/16 downcut works well in this same plastic so fingers crossed.

Does anyone know of other methods to cut plastic with an upcut bit and not have this problem?