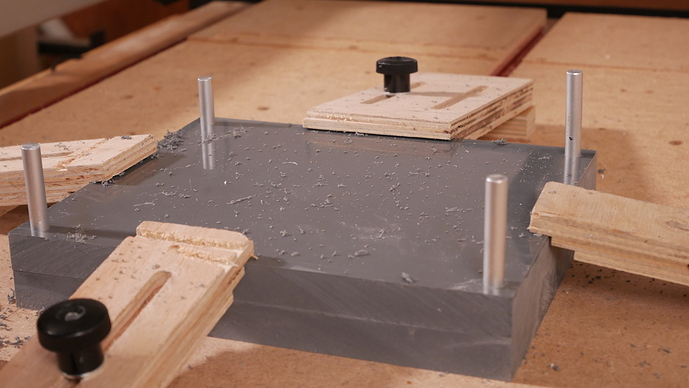

I’ve had reasonable success making jig boards with locating pins (8mm aluminium rod) and using the 3M blue tape suggested in this thread;

It sticks way better than the generic blue masking tape I was using before, so well in fact that I have to file a chamfer onto the bottom of the stock so that I can get under it to pry it up at the end of the job.

I have a couple of locating pins along the Y axis in the jig board to align it and then use a few M6 bolts into threaded inserts in the baseboard.

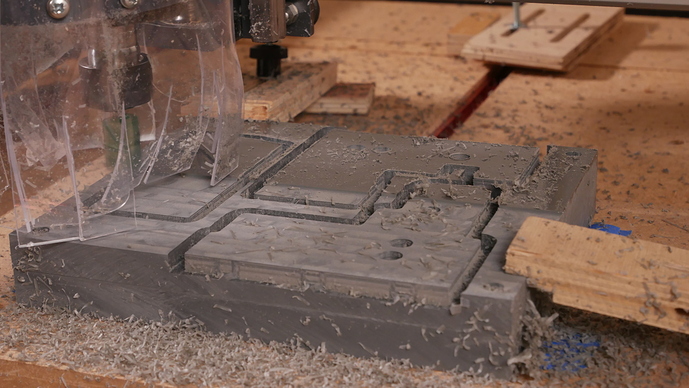

I have the Shapeoko bore locating holes through the stock matching the layout it bored on the jig / spoilboard below, in this case it’s so I can flip the part to machine the other side;

The clamping on top is really just for my comfort, given I can almost pick the machine up by the workpiece ![]()

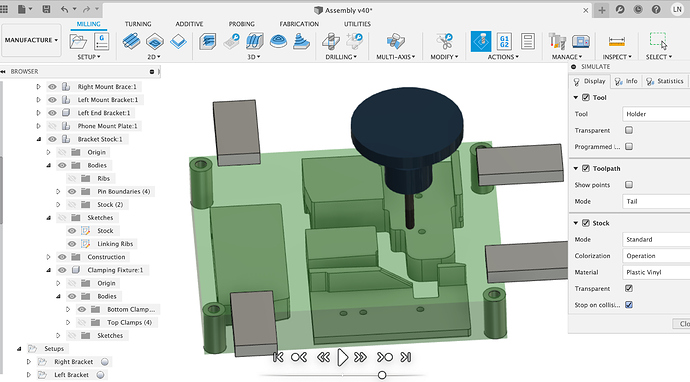

The pins are soft aluminium rod so that it’s not instant disaster if I send a toolpath or rapid through them. Make sure you extrude bodies for your clamps and locating pins in your fusion model then set them up as fixtures in your CAM job setup and “stop on collision” will then stop if you hit them during a CAM simulation.

Here I’ve got extruded cylinders larger than the locating pins and placeholders for my clamps to check if I’ve put too small a clearance height in and am going to rapid through them (again).