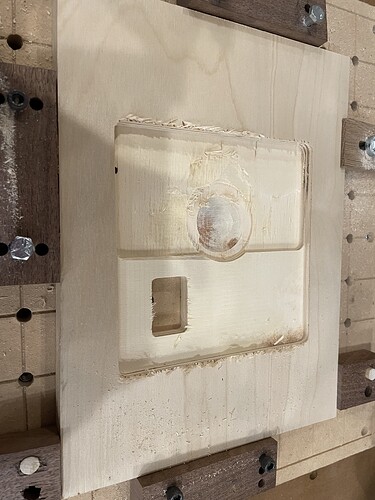

I tried my first project using the ideas from the “first five” projects carbide course (making a cell phone catchall tray. The designs all seems to simulate correctly but when it hit to the third pocket within a pocket for the charging disc it started drifting to the right. About 1/4” or more with each pass. It started in the correct location and did the first layer correctly but then went drifting. I checked to see if I’d lost communication but no. I checked to see if the tool had gotten too hot but no. The only difference between this cut and the previous was it is circular. Ideas?

Which machine is it?

Have you checked that it is mechanically sound and that all wiring is in good condition and secure?

What tool are you using? At what feeds and speeds?

Shapeoko 3 standard using 201 end mill at default speeds and feeds for that tool 1800 rpm

I just bought it used and it was working at the original owners place before I put it in my car and brought it home. I reassembled it and did some test cuts and it seemed to have no problems cutting a Celtic circle yesterday

The most common things for an SO3 is belt tension, belt pulley set screws not secure, v-wheels need adjusting. When the bit starts moving around it is almost always one or all of these 3 things for an SO3. The SO3 is a sturdy machine but you must check all of the above. Basically put your finger under the belts on the Y rails with the gantry all the way back. They should feel the same. Also the X belt across the top of the gantry should feel about the same tension as the y belts. Be sure the Z carriage is all the way to one end or the other. The set screws in the pulley of the X and Y and if you have a belt Z should have one set screw on the flat of the stepper motor and the other not on the flat. The easiest way to check that is to put a black mark across the end of the pulley through the stepper motor shaft. Then jog around and if the mark on the pulley and the stepper motor stay aligned they are likely ok. The last thing is the v-wheels. There are two on each end of the gantry and two on the Z axis. The top ones are all fixed but check to make sure they are not loose. To adjust the v-wheel use a wrench to hold the eccentric and slightly loosen the bolt. Then rotate the eccentric until the v-wheel is snug. Hold the wrench on the eccentric and tighten the bolt. When you push on the v-wheel with the power off it should move the gantry. If the wheel slips then you need to adjust it. There are two versions of the v-wheel eccentrics. The original had a smaller hex head and the later ones have a 10MM hex head. They both work the same way, just the size of the hex head is different.

Check all the adjustments with the Shapeoko powered off. Also with the power off move the gantry from front to back and back to front slowly. Feel if there is any binding or stiff spots. Do not move too fast or the stepper motors make back EMF force that feels like binding. Also move the Z carriage back and forth to feel if there are any rough spots. Also clean the rail that has the v shape the v-wheels ride on. They can collect dust and cause binding and/or damage to the v-wheels.

If you have a belt Z then you can manually move the Z axis up and down. If you have a Z-plus you can manually rotate the lead screw but it is hard and wont tell you much.

Edit: One last thing is C3D routers and Makita routers can have bearings go back and the router bit will move excessively if you power off the router and grab the bit and try to giggle it around. If the bearing is bad then you will feel the router shaft moving around. It turns but should not be loose feeling and turn off center. I have not heard anyone complain about Dewalt routers having bad bearings. The Dewalt was the default router for the SO3 when it first came out and later support was added for the Makita/C3D routers. The Dewalt is yellow and the Makita is a teal green/blue and the C3D is black and gray (I think).

I believe you mean 18,000 RPM.

Per the machine operating checklist: Machine operating checklist , the basic points of adjustment for a machine are:

- (for belt drive machines) Pulley set screws — verify that these are in-place and secure — be sure to check all axes/pulleys (including Z on machines w/ belt-drive Z-axis, for an HDZ, check both coupler screws).

- (for the SO3/4, X- and Y-axes, and the belt-drive Z-axis on Launch and summer 2016 SO3s) V wheels / eccentric nuts (per assembly instructions)

- (for the Pro, Pro 5, HDM, and Z-Plus and HDZ Z-axis) Lubrication of the linear rails: CNC Machine Maintenance c.f., https://web.archive.org/web/20211127125707/https://docs.carbide3d.com/assembly/linear-guide-maintenance/Linear_Rail_and_Guide_Maintenance_02-17-2021_v1.0.pdf

- (for HDZs, and HDMs, and SO5 Pros) check that couplers between the motor and ball screw are secure, for the SO5 check that the DAC which transfers the rotary motion of the ball screw to linear machine motion is secure on the carriage/gantry

- (for belt drive machines) Belt tension (see the relevant step in your instruction manual, Note that the X-axis motor is held in place on standoffs and if those bolts are loose this can cause belt tension issues. Also, belt tension for the Y-axis stepper motors needs to be even/equivalent on each side — a significant difference can cause skipping on one side eventually resulting in lost steps on both. Measuring belt tension, squaring and calibration

Naturally, this assumes that all the wiring is in good condition and all connectors secure per the Machine Operating Checklist. Verify that all wiring is in good condition and all connectors are secure, and that all wiring leading into connectors are properly in place and are secured so that the wiring leading into and away from connectors will not shift.

A good video overview on setup:

Tramming the Z-Plus: How to Tram Your Shapeoko - YouTube

Ensure that all screws are in place and secure, esp. on the linear rails on a Pro.

Yes rpm (auto correct is not my friend). I will look at this checklist. Thanks for all the recommendations! Jen

Thanks so much for the great recommendations! That’s a huge help and I grateful appreciate the assistance! I’ll give these a try. Jen

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.