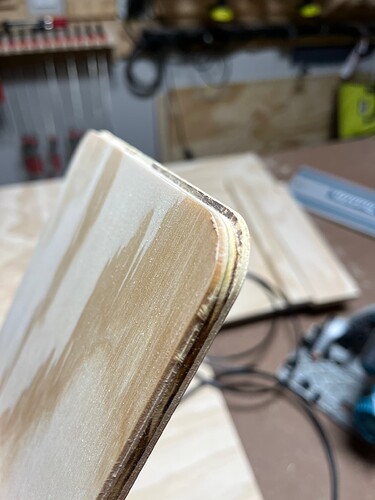

For the life of me, I keep getting uneven cuts to the right hand side of my work. All other sides are good and clean. This just started happening with the last couple of projects, please help

Hi @Bporter24,

Shifts like that typically mean one of two things: either a mechanical thing causing the pulleys to slip, or it’s a stepper motor losing steps.

- when this happens, jog to (X0,Y0) right after it happens: you should be able to confirm whether the X zero has been altered during the cut and it’s not where you originally set it anymore.

- the two most likely culprits are

- (X) pulley slipping on the stepper motor shaft. Check whether the X motor pulley still has its two set screws in place, that one of them is ideally positioned against the flat on the motor shaft, and that both are still tight. A good way to have evidence of pulley slippage is to draw a black marker line across the pulley and shaft face, then run the job and if you have the slippage problem, go back and inspect the pulley: you should be able to tell visually whether it has slipped or not (broken marker line)

- a collision with some object on the left of your job. Or hitting the left travel limit. If this happens, during the collision the X stepper motor will lose its X reference, and then move back further to the right that it should have.

If it isn’t that, contact support@carbide3d.com and they’ll troubleshoot this with you.

Thank you; I will follow those instructions in the morning and let you know.

Slippage can also be caused by pushing the machine too fast/hard through a material or using the wrong bit. I’m unsure on your tool paths but do note what looks like some burning. I’d check your feeds, speeds and bit as a port of call.

It looks like you are cutting weatherboard ply. This can be a pain to cut, because it’s made up of varying qualities and types woods all laminated together. If you can get it, birch or furniture grade ply cut much better as a whole.

One additional thing to consider is if you are cutting a slot just as narrow as the endmill (slotting) — this results in constant high tooling engagement — where possible avoid slotting and add geometry and cut as a pocket

and/or

and consider leaving a roughing clearance and taking a finishing pass.

Thank you, noted and I will make the correction(s) ![]()

I inspected the (X) stepper pulley and while both set screws were intact, the flat portion of the pulley shaft was shifted just enough to allow some play. While I was at it, I checked and tightened the (X) belt and then prayed to baby Jesus as I ran multiple tests- no more shifting of toolpath(s)!!!

THANK YOU

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.