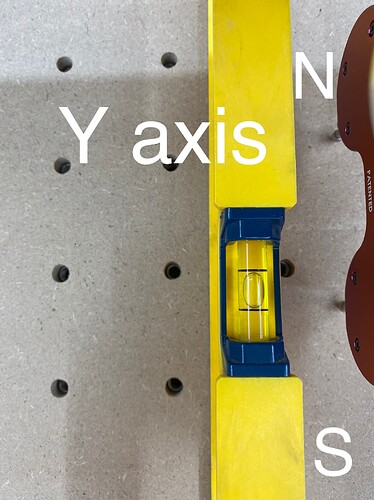

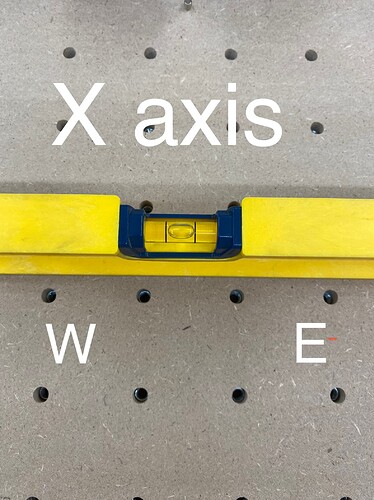

1st, put the level away. It means nothing. unless you’re using it to judge the flatness of the wasteboard.

That or a precision straightedge…

Either one. But the surface should be recently surfaced flat, and then checked for flat.

Use the straight-edge or level to check flatness front to back, side to side, and also on diagonals.

If not flat, shim the machine to get it flat.

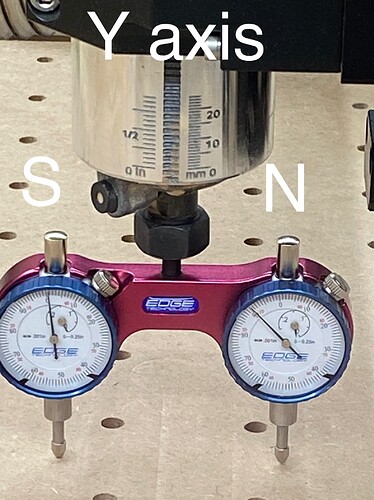

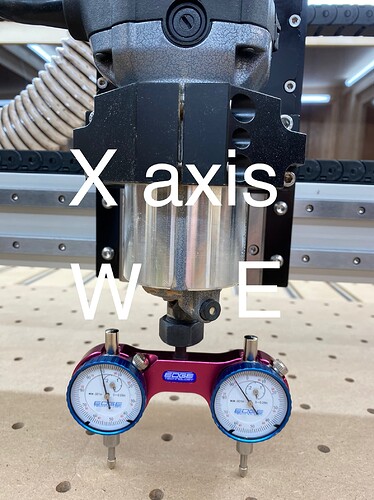

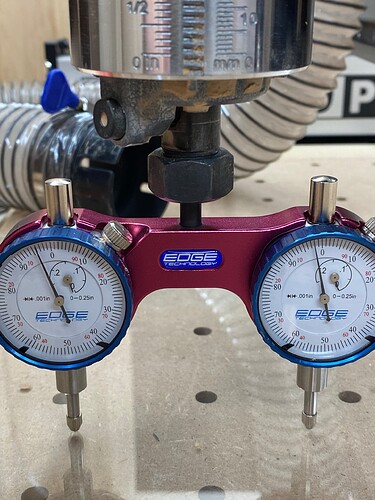

Next, calibrate your tramming tool. Move one probe down to a solid surface (1-2-3 block, parallel, anything flat & solid) until it reaches zero, or moves the needle a bit & set the dial to zero. Lift up, spin the tool, and set the other probe to the same zero.

Now when you lower your probes to the table, lower them until the 2nd dial reaches zero, and read the other dial for your “High spot”.

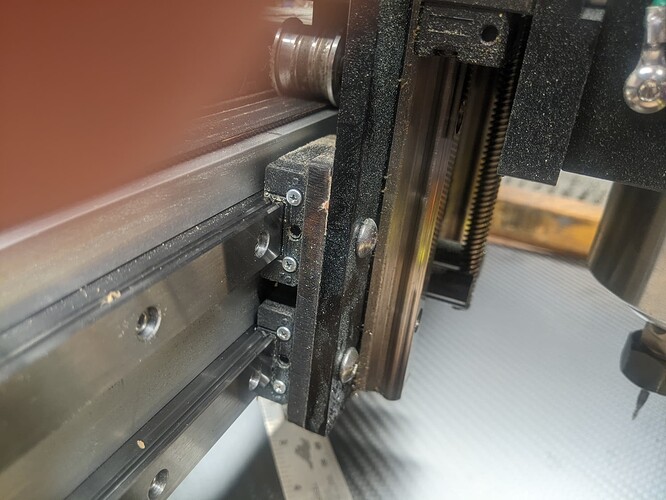

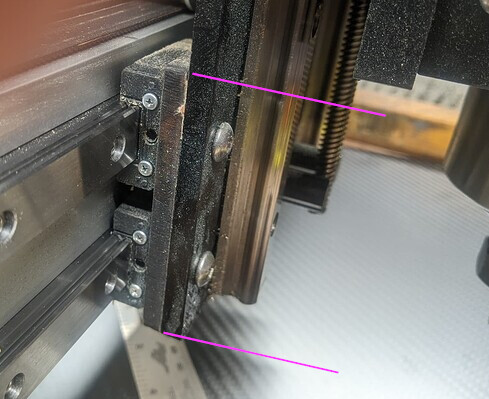

I do Y first on my HDM, and I shim the Z axis mount to get it even. If you shim the motor mount, the axis itself is still moving at a slight angle. Your tool will be perpendicular, but not at the same Y position as it moves up & down.

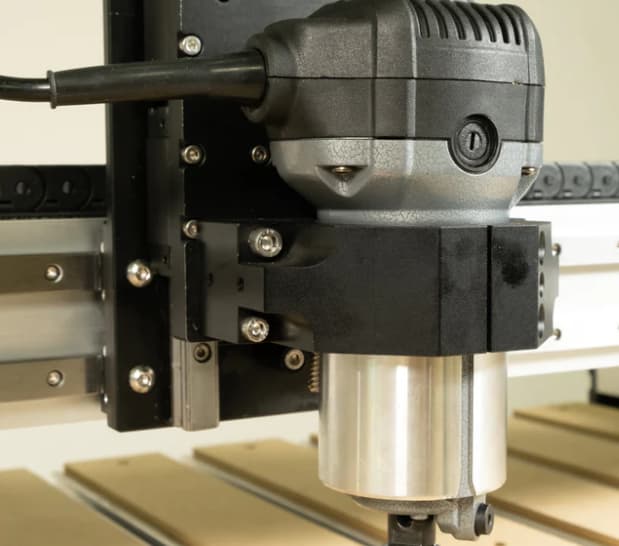

For the X, I crack 3 of the 4 motor mount bolts about 1/8 of a turn or less, just to loosen them, leaving one of them tight. Gently tap the motor mount until the indicators are even, then re-tighten.

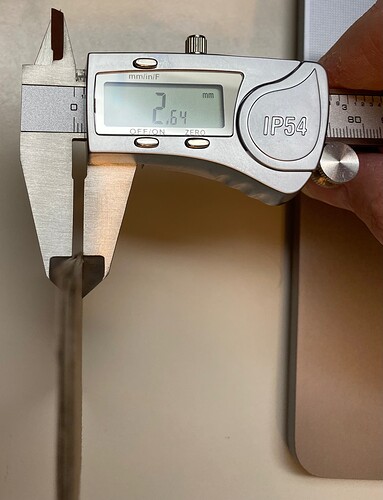

Not sure the size of your indicators, or the tolerances you’re shooting for, but I would say if either axis was off by more the 0.005" I would resurface the slats or spoilboard after tramming.

Now you’re ready to calibrate the 3 axes, and check the XY for square (If you choose to do so.)