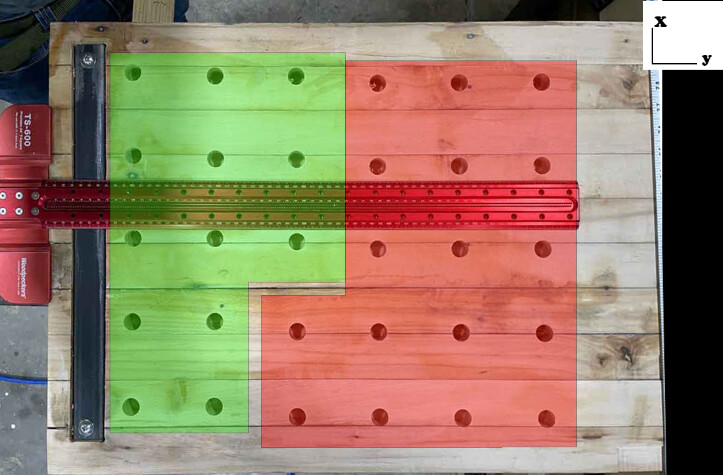

I’m really confused. I should have done a test cut before cutting my workbench, but the holes are all over the place. I thought I did a good calibration. The holes are all perfect, but not aligned to the grid at all.

What program did you use for the design? Can you post the file?

Yes. In a bit when I can get to my computer. The machine seems pretty accurate and the holes are perfect I used fusion 360

Tim

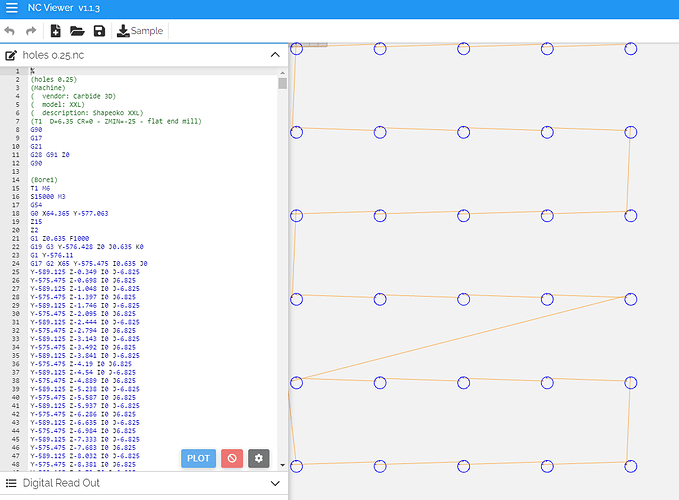

Does this work?

gcode is fine (as was to be expected)

What machine do you have ? I would say check it mechanically, starting with pulley potentially slipping (draw a mark across the pulley and motor shaft, run your job, and if is turns out weird like this one go back and inspect the mark, if the pulley slipped it will be obvious)

3 xxl

Shapeoko CNC Router - XXL Size / Carbide Compact Router - Sweepy 65MM / Z-Plus

Purchased in march 2020

Looks like the X pully? Any links on that?

It’s been cutting signs so well. Why would a boring operation be so off?

Looks like the holes align well vertically in your second to last and last picture (horizontally in your first picture), but there is a shift between “lines” of holes.

Determine what axis that is (hard to tell from the pictures) and then:

https://docs.carbide3d.com/shapeoko-faq/shapeoko-3-how-to-check-the-pulley-set-screws/

The good news is the holes will work. They may be ugly but using bench dogs and clamps will still work. I am sure you would rather have nice neat holes but sometimes the best laid plans of mice and men go awry. After you get your issue fixed you could plug the holes and start over but at some point it is diminishing returns on a workbench. If you plug your holes just move the holes over so you dont make them overlap the old holes.

I agree. This looks mechanical. Belt tension is usually the first culprit.

Thanks for the answers. I’m at home now and can troubleshoot this, but even if the belt were loose, it wouldn’t fully explain the level of variation I am seeing in the different rows of holes.

The cuts themselves are extremely accurate and consistent within each individual hole, but the issue lies in the fact that the rows themselves are off in the x-axis. This is causing a noticeable discrepancy in the final product. It is like something is slipping but then staying in place, not like a loose belt. Maybe this is a loose set screw.

In any case, I’m hoping to get a working theory as to what may be causing this issue and how it is resulting in this particular effect – any insights or suggestions you may have would be greatly appreciated.

again, really appreciate your help. Feel like I can’t trust the machine on nice pieces like this and would love to get to an understanding so I can check this in the future. A test cut would have been good, but even then I would like to understand what can cause this behavior.

Thanks!

Tim

Were you cutting right at the X or Y limit of the machine?

If so it’s quite easy to run the axis into the end stop (or foul the dust shoe or similar) and knock the machine out a few steps for the next pass.

The most likely problem is something mechanical — if everything is cutting well otherwise, then @LiamN 's theory of the machine running up against the limits of motion is likely.

It’s all pretty straight-forward:

- Grbl receives G-code and based on that sends signals to the stepper motors via the stepper drivers

- if the wiring is in good condition and all the connectors secure, then the motors turn per the current received

- the pulleys or the lead/ball screw rotate as they ought if securely coupled w/ the shaft (check the pulley set screws and coupler set screws)

- if the belts are in good condition and properly tensioned/the lead nut/ball screw nut body are in good condition, and if need be properly lubricated the axis moves so long as nothing mechanically interferes w/ the motion and the machine is able to overcome any cutting forces/resistance so as to move as directed

- if the linear rails/blocks/Delrin V wheels/alu. V rails are in good condition/properly lubricated and properly adjusted so as to enforce strictly linear motion along a given axis

It’s a machine. If properly assembled and maintained and calibrated and used, “it just works”. If something goes wrong, while the motion seems complex when considered as a whole, if one breaks it down and considers it one axis at a time, it all becomes pretty obvious.

Did you check the pulley set screw?

hmm . . i’m pretty sure I wasn’t. let me check that – would that explain the pattern or just the edges?

Anything that causes an axis (just one from the look of your pic) to lose position could cause this effect.

As Will says, it’s most likely a pulley set screw or some other machine item, if not that then it might just have run out of travel, I’ve hit the end of travel thanks to a dust shoe on a clamp before, the momentary grinding sound of unhappy stepper gives it away if you can hear that over the router and vacuum.

Tim,

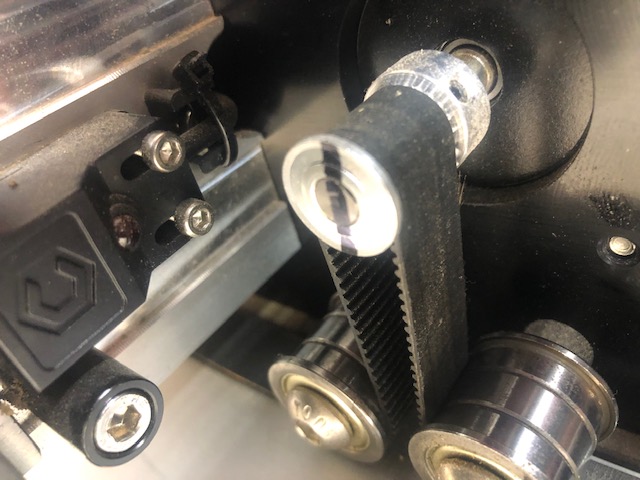

This is what I did to visually check my pulleys.

Here’s how I fixed my pulley set screws ![]() (Zman and I need to start up a routine - lol)

(Zman and I need to start up a routine - lol)

Blog post here:

https://www.theboohers.org/?p=3568