I recently upgraded from the S04 XXl to the S05 4x4 with the new 80mm spindle and VFD and I’m having some issues.

I got the machine setup two weeks ago and flattened the spoil board with no issues. I came home last night and have tried to run two jobs. One using carbide create/carbide motion and one using Aspire/carbide motion.

I don’t have bit zero since they are out of stock. And it’s not like I haven’t set zero manually 100 times on my old machine, but for some reason when I try to set my zero, it moves to the XY fine but has buried two bits though the material and the spoil board.

And most of the time when I try to set zero it will go to bit setter and measure the bit, but will start moving to zero then stop and go measure the bit again. Over and over.

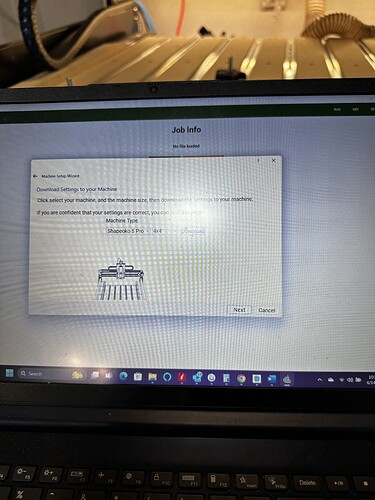

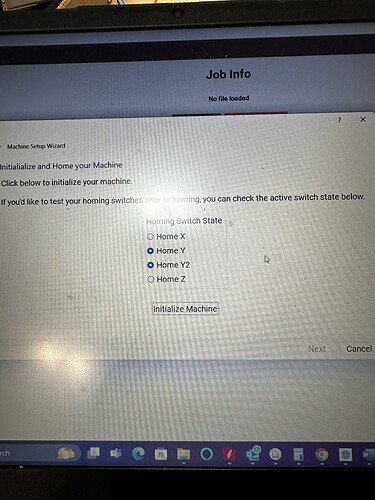

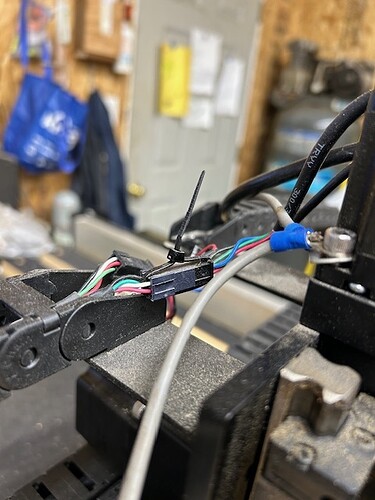

I’ve gone through setting up the new machine multiple times, I’ve checked the connections, but nothing seems to be working.

I’m guessing that it has something to do with the control board or switches.

Has anyone experienced anything like this? Any ideas what could be wrong.

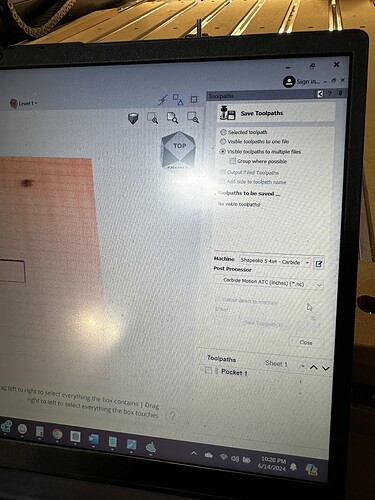

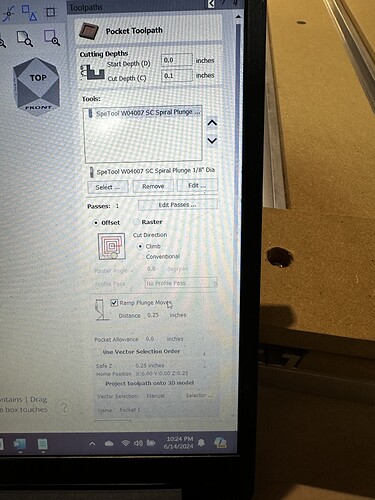

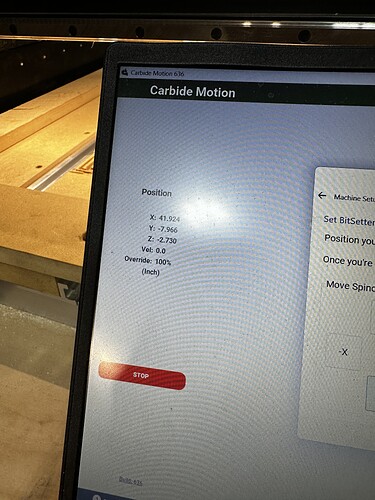

I attached to pictures of the settings(it won’t let me upload video, but I have that too.

With the z all the way up it’s only showing a z height of a little over an inch.

I figured I’d ask here before reaching out to support. Since it’s the weekend and maybe someone will see something I’m missing.

I appreciate any help I can get.

Best,

Justin