Once I’ve started my Shapeoko upgrade path I didn’t thought it would be this deep hole to fall in too.

How deep ? It’s turtles all the way down!

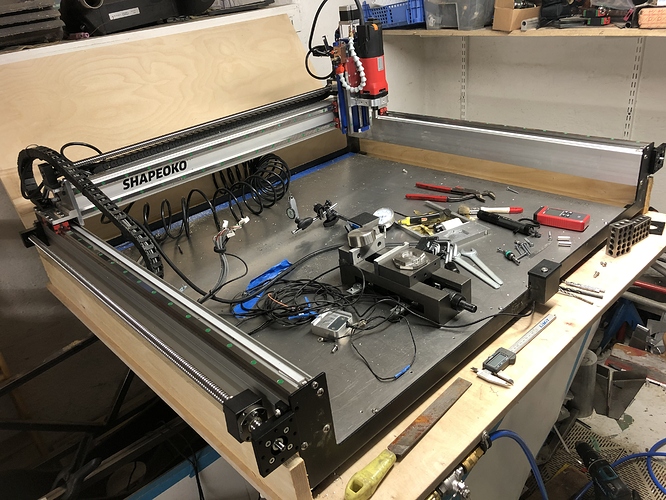

Anyway, how do you like those ballscrews ?

If you were so inclined would you mind cutting a disc, any size, in acrylic or aluminium, and post a close-up of the wall finish in that thread ? I would be interested to see if the extra resolution you get with those ballscrews is showing (in other words, I’m looking for an excuse to upgrade too)

You work fast. We the people would like a wide shot of the newly outfitted machine!

If you reach the bottom of the rabbit hole shout up to let the rest of us know how much farther we have to go…

Yes I’ve noticed that :).

I could do that but it will take a few days to manage.

Have just done some dry runs so far.

I don’t think I want to show to much until I’ve got some proper parts made. Now it’s quick and dirty setup.

I am soooo glad I am too lazy to do anything but buy a kit that bolts on!  That looks great! Can’t wait to hear how well it performs.

That looks great! Can’t wait to hear how well it performs.

Ditto.

The question is: do you want to mess with the machine? or do you want to make stuff. Sometimes making stuff requires messing with the machine, but, generally, is is easier and less pricey to just get a machine you need not mess with.

There are two kinds of people … and then there is everyone else. ![]()

This is something from both sides. I don’t have space for a commercial mill except a Datron NEO would fit but that waaaay to expensive form me.

And now my Shapeoko let me do almost any materials I can get hold of.

Now it’s been a while but I have now got almost everything together again. @Julien mentioned resolution in a comment and I actually didn’t think of that until then. So I’ve ordered more screws and have just finished mounting them.

And now my enclosure is to small so will have to make a new one too.

I will make some test cuts tonight I hope :).

The perfect size for an enclosure seems to be [size of the enclosure you think you’ll ever need] + [size of that next upgrade you don’t know about yet].

You guys with your rails and screws are taunting me !

Do you mind sharing the total upgrade cost (ballpark value) for those 4 rails+ 3 screws ? I’m still alignment-shy but one day I’ll overcome that feeling and follow that white rabbit too.

Ooo some were around 1500€.

You shouldn’t be afraid or the alignment it’s sort of self alignment if you mount the first rail straight the other one tags along so to speak.

The scary part is that the machine doesn’t crash “soft” any more, it snaps bits fast if you mess up.

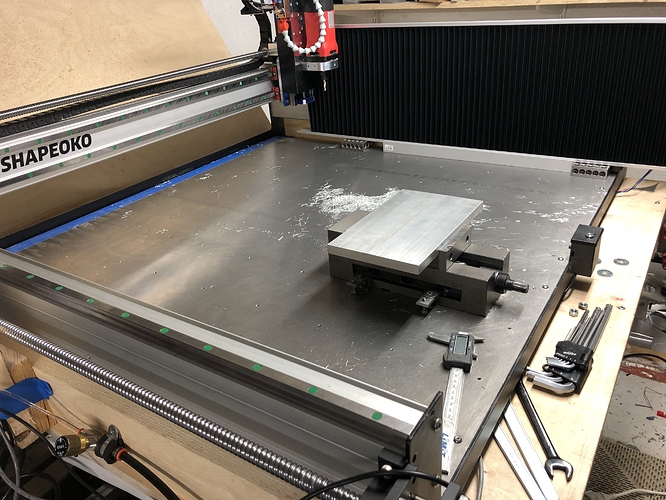

And now I can confirm that my 15mm Aluminum plate needs bracing. When cutting in tough metals the axial forces are getting so high that it sort of lifts the vise and the plate upwards and that kills endmills.

But other than that it’s humming along nicely.

Cut is 0,2mm wide and 7mm deep

~11000rpm and 1200mm/m feed.

Could you do some test 1/4 holes possibly with a 1/8 single flute in 1/2 aluminum and see what kind of taper you are getting please?

I could but I wouldn’t use that small tool if I want it to be precise.