I would expect that it would be dead center of the bit, no matter what size of the bit, but that surely didn’t happen to me with a custom bit.

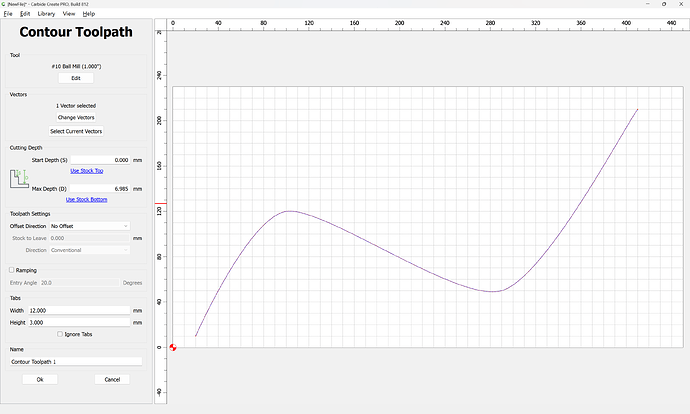

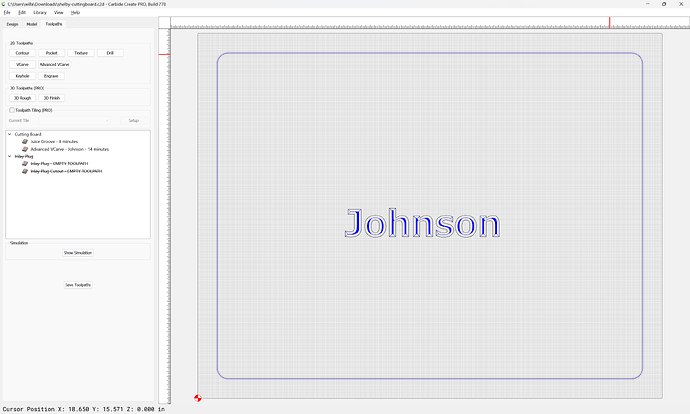

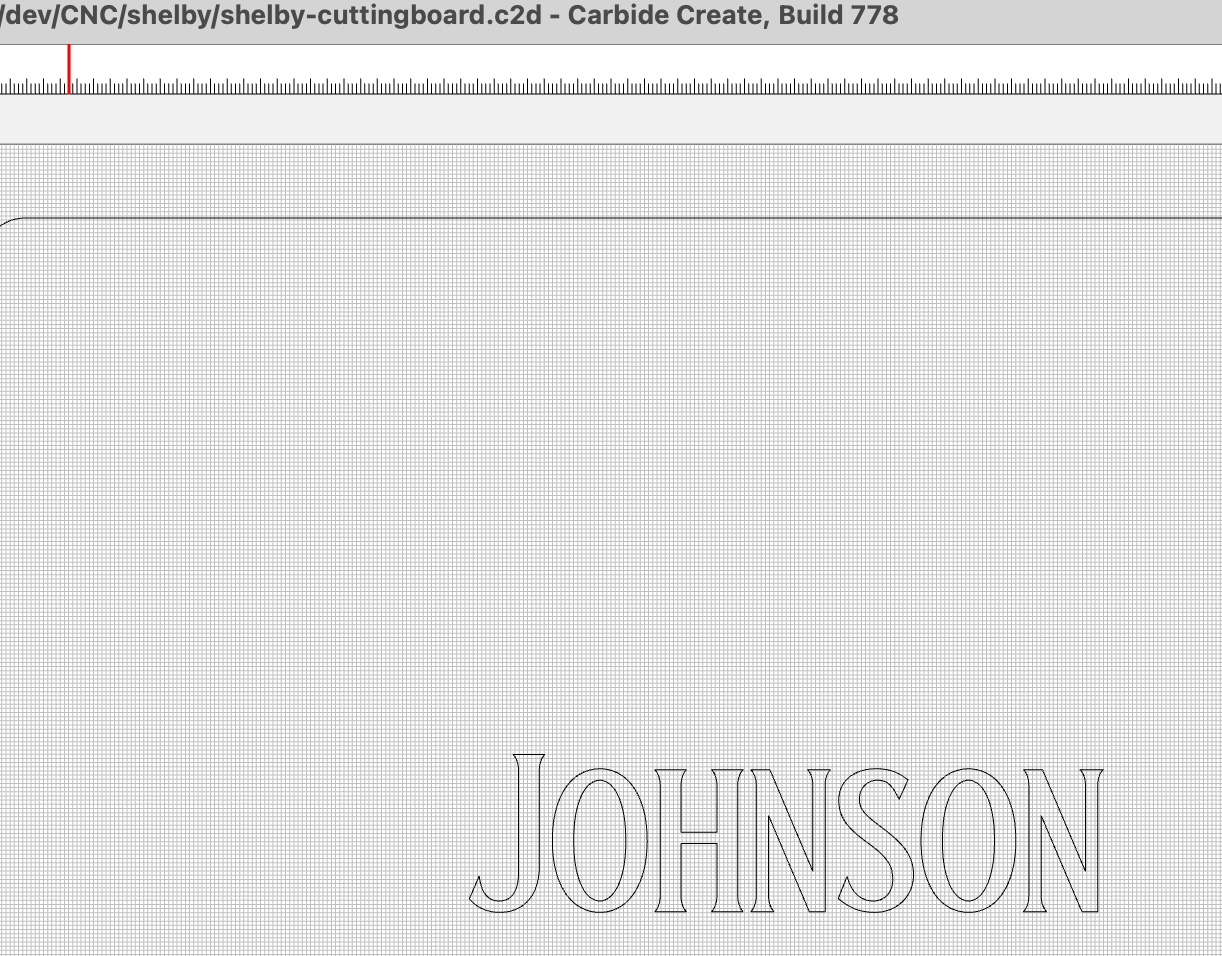

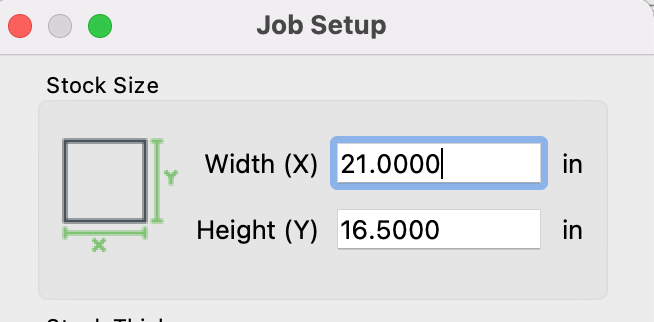

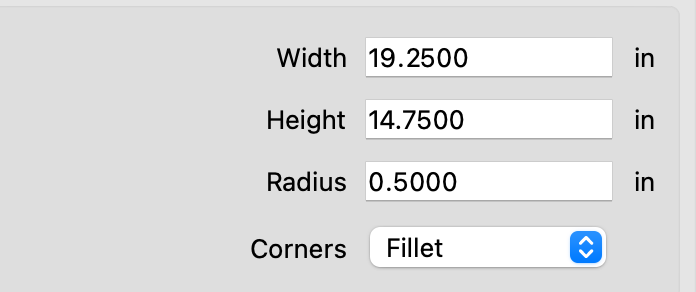

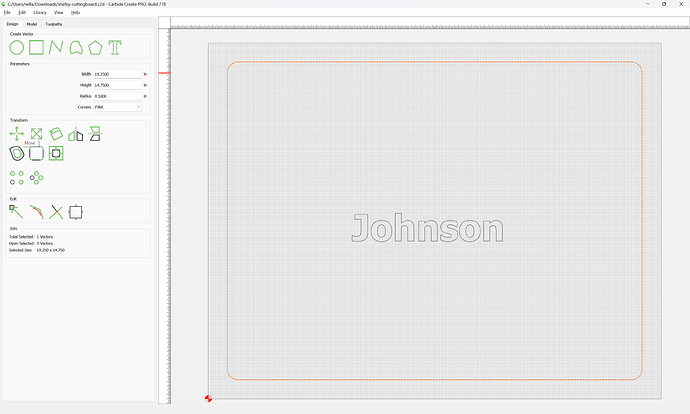

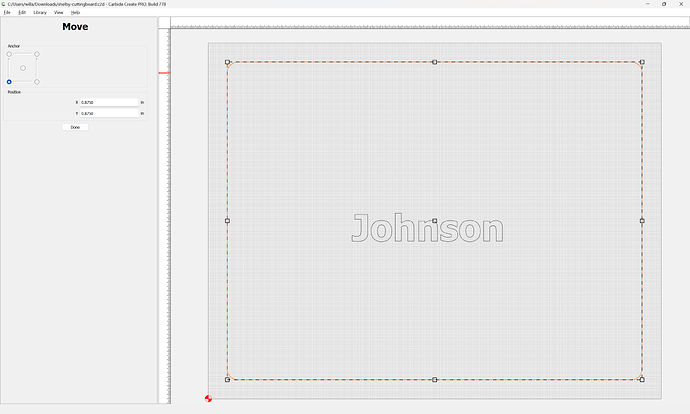

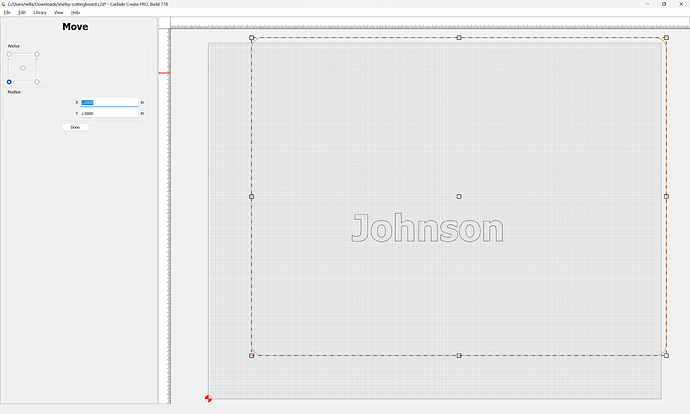

I used the following 3/4 Bowl and Tray bit and it seemed to use the inside of the bit. I had a square drawn 2" from the edge of my work piece (it was a cutting board doing a juice groove) with a no offset. I was expecting the middle of the bit to be 2" from the edge of the board. So with this bit was expecting it to be at 1.625" and 2.375 but what seemed to happen was the edge of the bit was at 2" middle of the bit was at 1.625 and the other edge at 1.25.

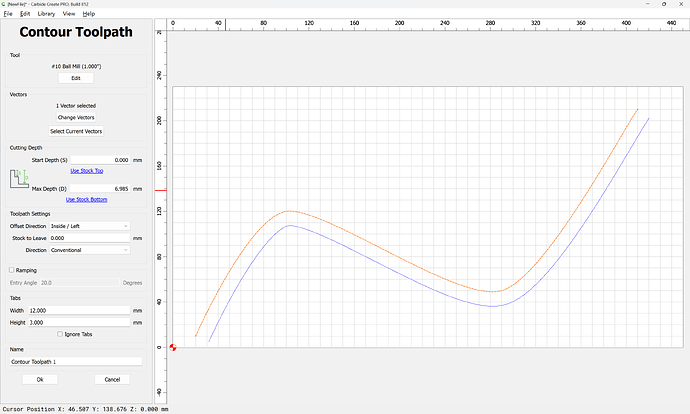

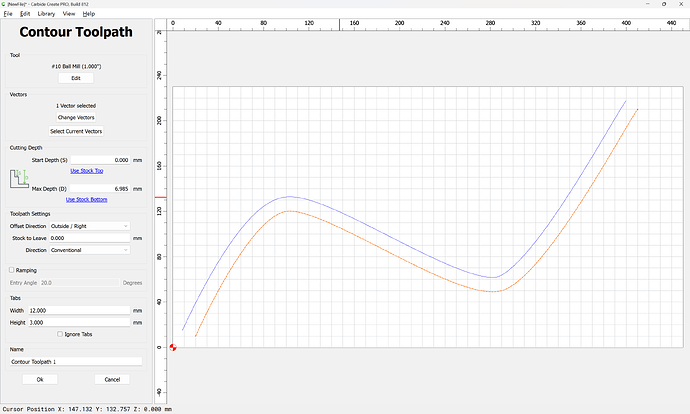

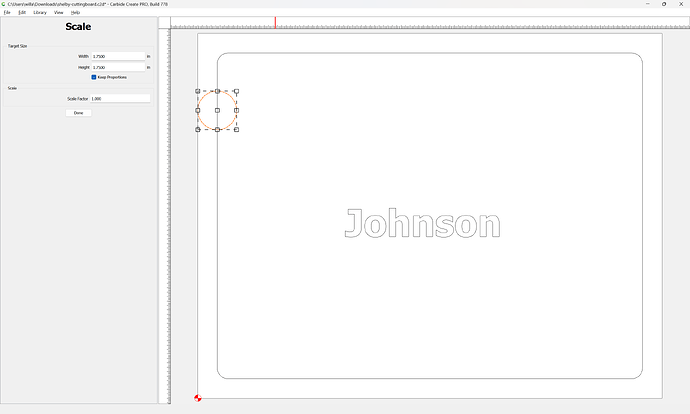

I double checked and I had it set to “no offset”. Is my expectation wrong on how “no offset” is being measure?