How do you specify a contour toolpath to start from a specific location from outside your stock piece and then move in from there to a specific starting location of your contour toolpath to complete the cut?

See:

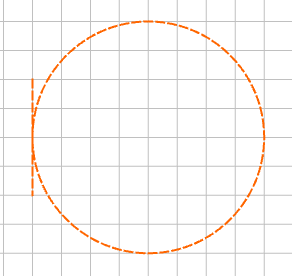

just make the geometry larger than your stock.

An example of what you’re cutting and the stock would help.

But generally, you can draw in a toolpath & follow it with a No Offset Contour.

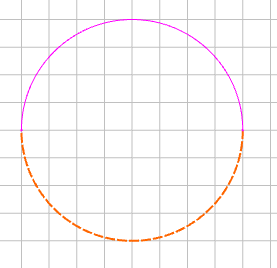

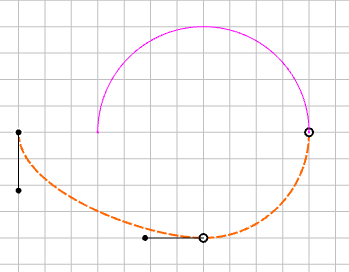

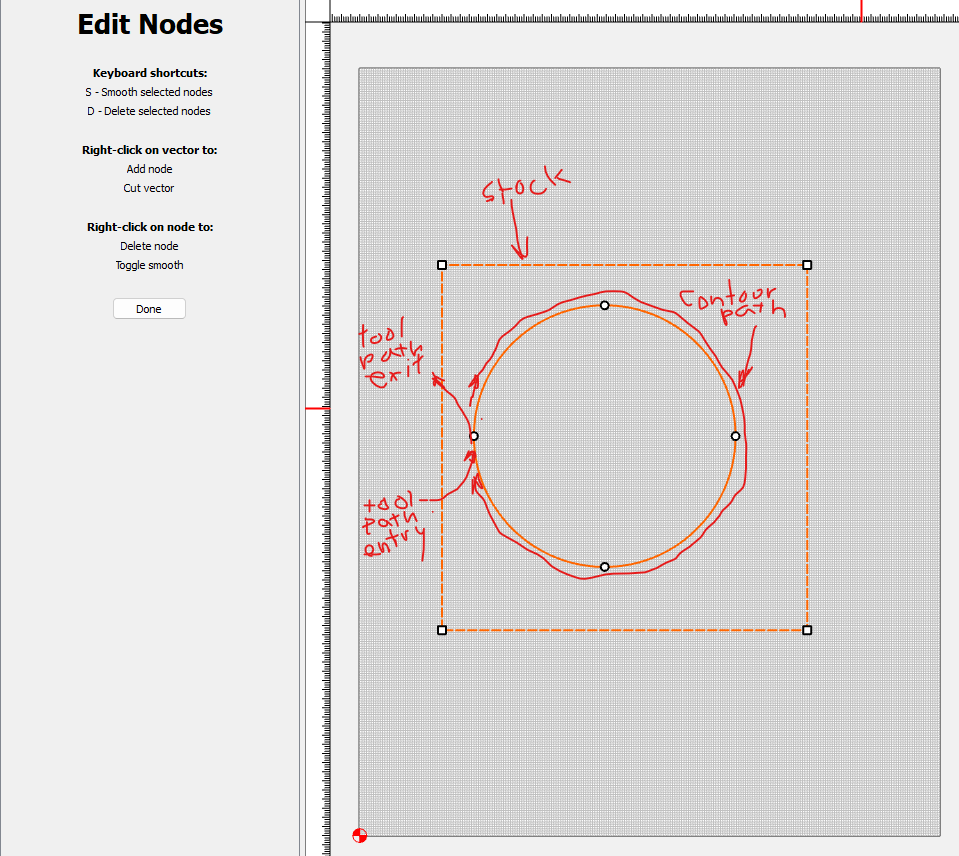

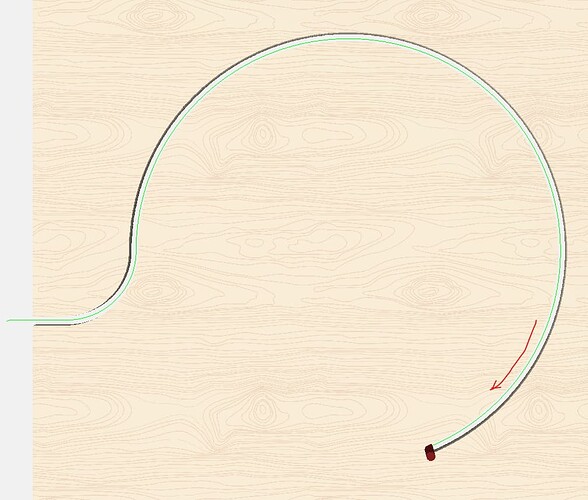

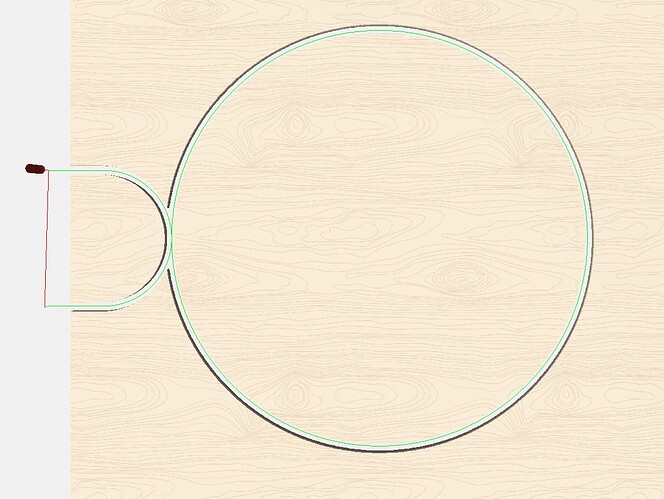

If I want a contour path around a circle with lead-ins, split the circle into 2 semi circles

Move one of the nodes

Add your lean ins

Join the curve, Node edit & select both nodes and move them back…

Create your No Offset Contour path.

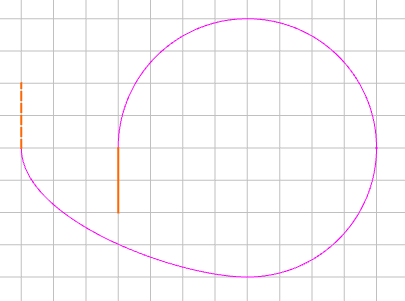

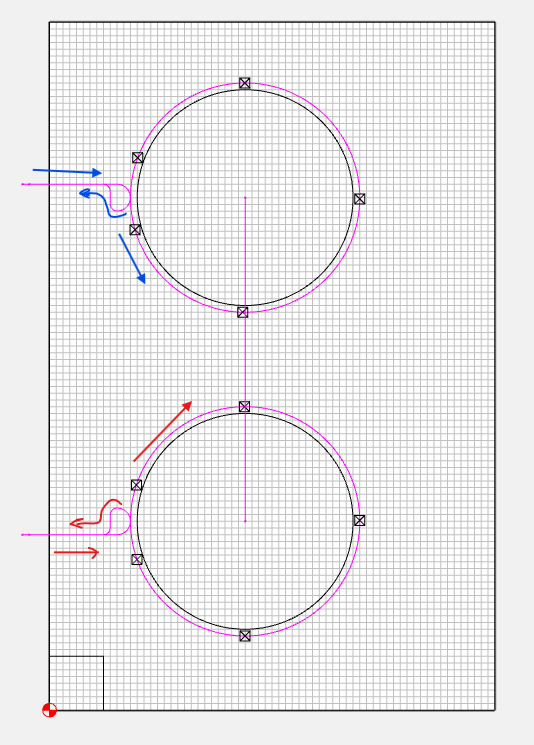

It’s conventional cutting, and I want to climb cut, so I mirror the curve vertically

Tod1d,

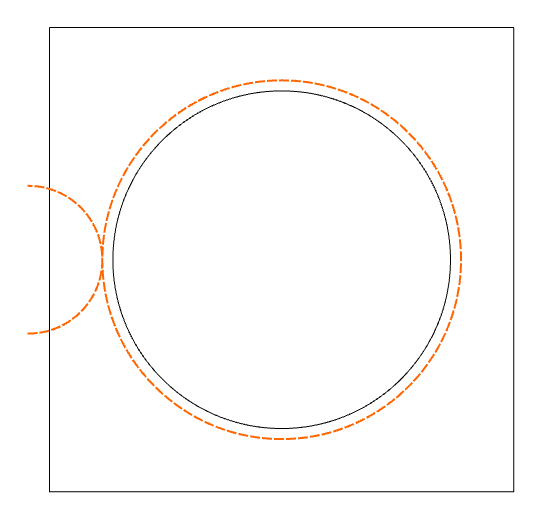

Thank you for your assistance. I don’t have a specific piece or stock I’m cutting. I just want to understand how to use this feature in CC so I’m just working with basic shapes like a circle in a square. The square would be like the stock piece and the circle would be what I want to cut a contour outside cut from the square to the depth of the stock (say 0.5 inch). The contour cut toolpath would start from the outside of the square stock and move to the circle cutting all the way around the circle and then exit out of the stock piece once the tool goes all the way around.

I replicated your initial instructions for splitting the circle into 2 semicircles and then doing the node edit to add your lead ins for the tool to enter and exit. However, you lost me with the comment about wanting to do a climb cut and mirroring vertically. I’m not sure what you mean by a climb cut and why it needs to be mirrored vertically. Could you clarify? Also, if I want to leave the boundary of the circle perimeter, why are you recommending cutting a no offset contour path? I would think I would need to do an outside contour cut.

Your help is appreciated.

If you draw your own path and the vector intersects itself, you will get odd results with an offset toolpath. To do an outside contour, offset the shape by the radius of the cutter & proceed as described above. If you want circular engages, just use arcs instead of lines for the leadins.

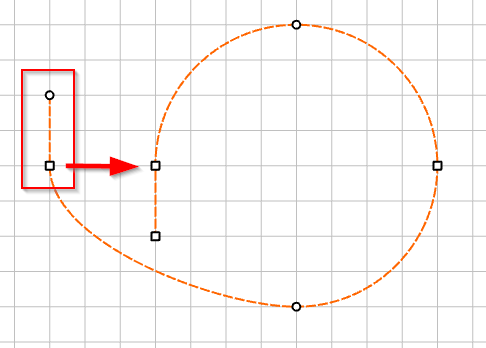

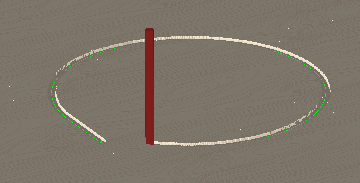

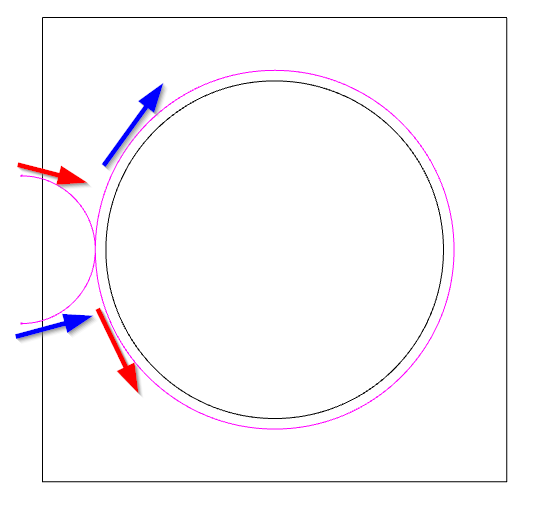

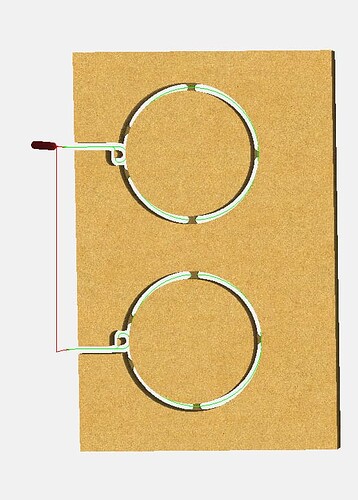

Conventional cutting the outside of a shape goes CCW (Red), climb cutting goes CW (Blue)

Google them, but essentially conventional pulls the tool toward the part, climb cutting pushes the tool away from the part. Climb cutting leaves a better finish, but if there is deflection you may need to cut it twice.

There is no option to switch between them in a no offset contour. But an open vector has a start & end, so if it’s symmetrical you can mirror it to swap the start & end.

Hello Tod1d,

Thank you so much for your reply with all the detail and explanations about my request. You have provided valuable insight of CC capabilities I was not aware of and was not able to find from carbide’s documentation. I have created a test piece to try out your suggestions for cuts I’m trying to make. I will keep this info in my personal CC tricks folder.

Thank you again

Hi Tod1d,

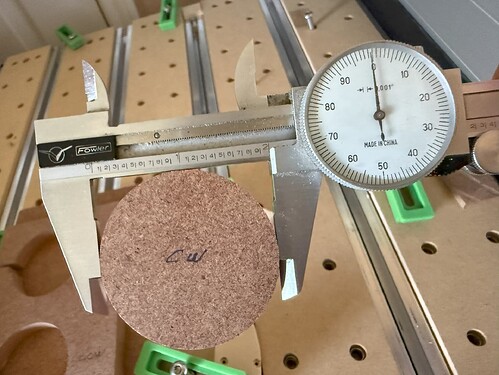

Following up on my posts. I created 2 contour toolpaths shown to make 2" diameter disks using your technique on CC with an 1/8", 2 flute upcut bit, but with cutter entry and exit to/from the same stock location. This worked out great with a 1/2" MDF stock piece. I created each of the 2" disks shown starting the contour toolpaths entering from outside the stock piece and exiting the at the same entry location. One disk was cut with the CW climb cut by vertically mirroring the contour toolpath and the other was cut with the conventional CCW contour cut. As you stated the conventional CCW cut disk would be a slightly smaller diameter due to the effects the cutter pulling away from the part. The resultant cut disks diameters measured 2.0" (CW climb cut) and 1.991" (CCW conventional cut).

I am not sure how this method of contour toolpath cutting would work with aluminum stock since I have used my Shapeoko to cut aluminum. I’m not sure is an 1/8" upcut bit would be appropriate for aluminum. Would need a recommendation of speed and feed rate for such a bit.

There are feeds and speeds for the #102, #102Z, and #274Z in aluminum in Carbide Create.

I’d recommend the latter as discussed in the videos listed at:

Thank you, Will. Helpful information

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.