WillAdams

February 3, 2024, 3:29am

21

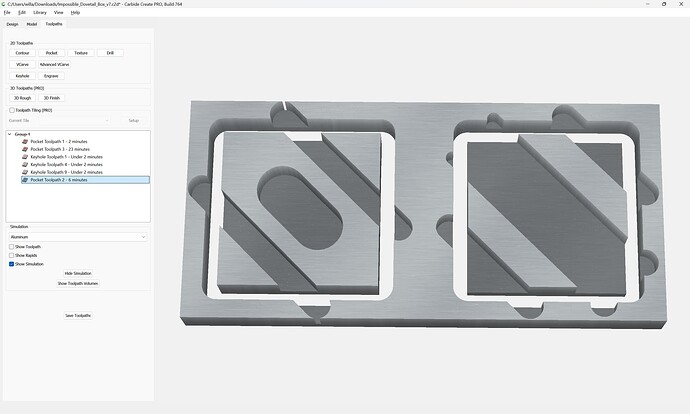

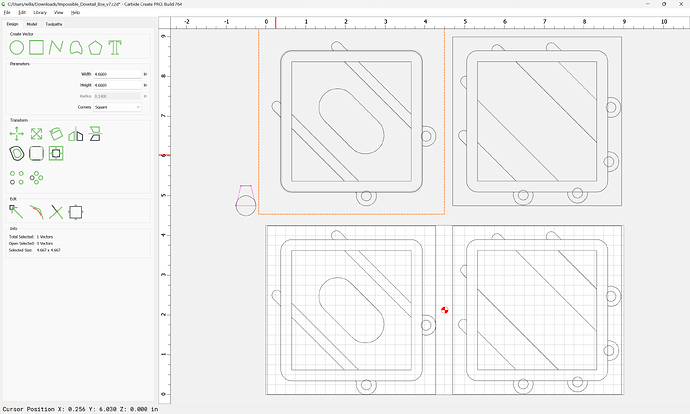

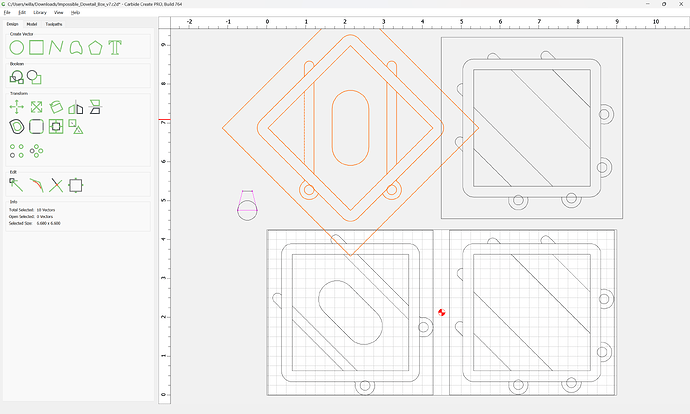

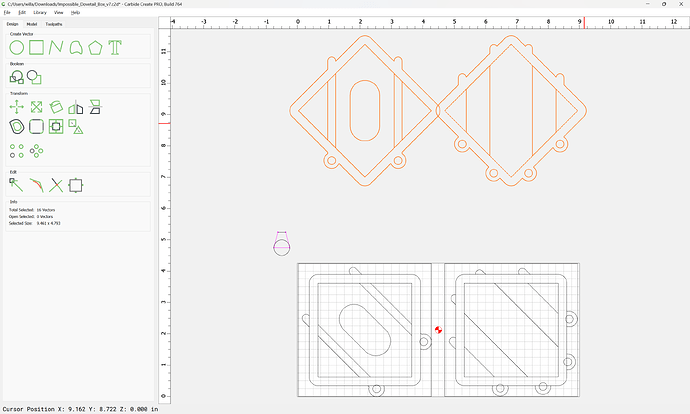

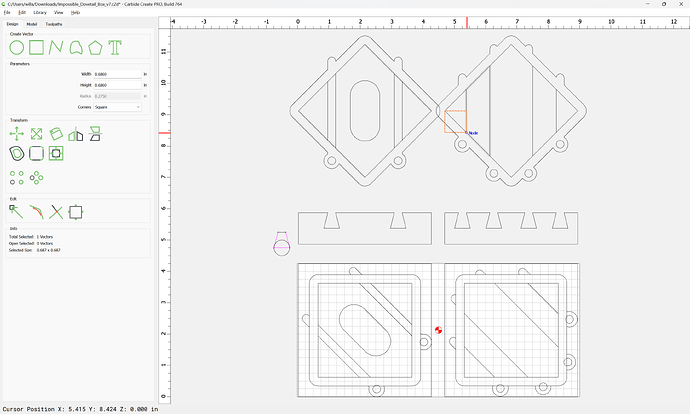

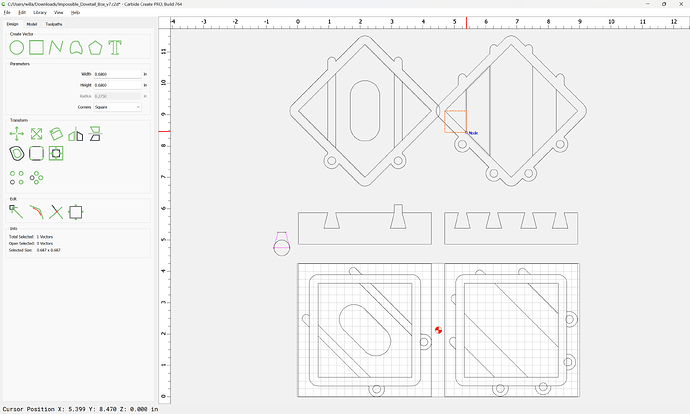

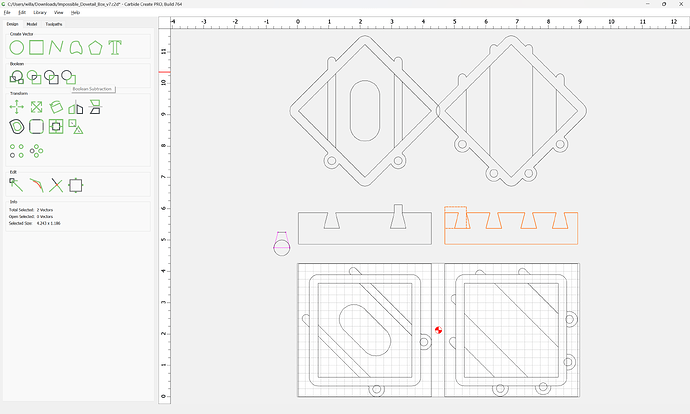

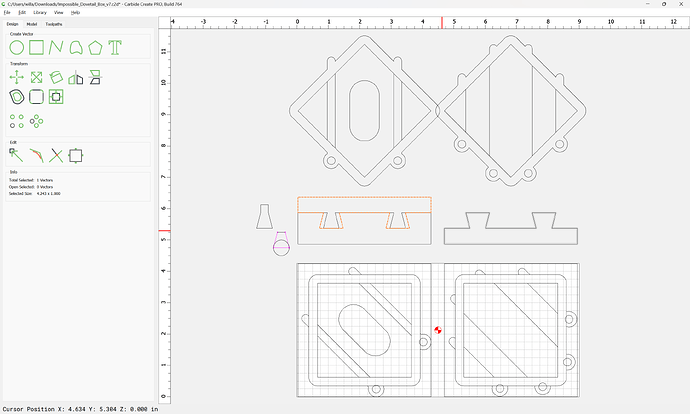

Reworking the design to take the use of the Keyhole toolpath into consideration we have:

One further improvement will be to chamfer the corners (we will also do this to the top/bottom after machining).

Lastly we will save in two separate files, for the bottom and lid, and adjust the thickness for the latter.

DAH

February 3, 2024, 4:41pm

22

Sorry, I missed that. I should read more carefully.

1 Like

WillAdams

February 3, 2024, 9:37pm

23

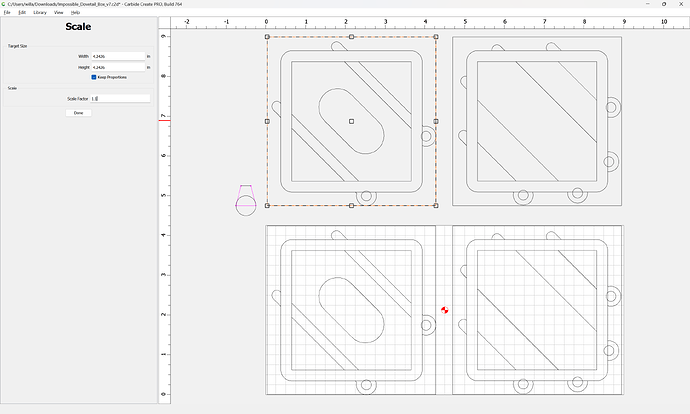

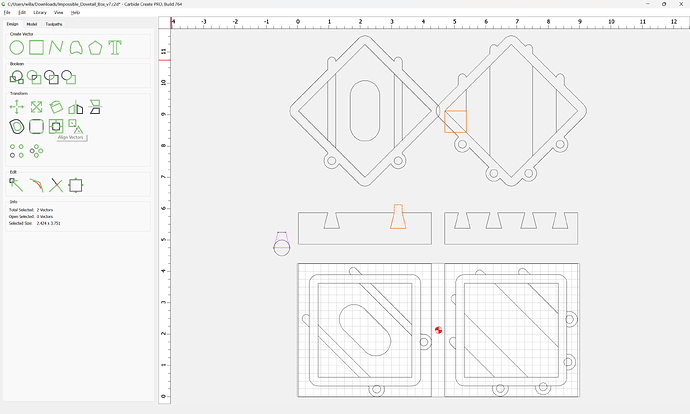

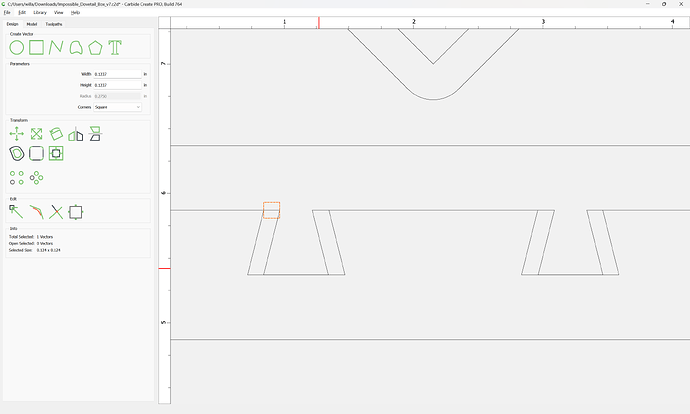

Before committing to separating the top and bottom as two discrete files, we verify the design by working out what the cut will look like in profile:

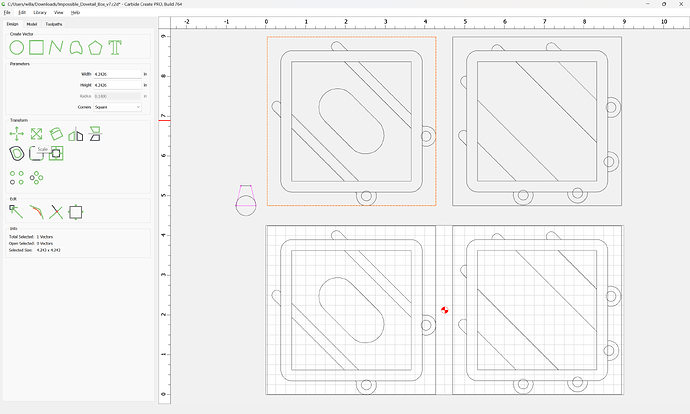

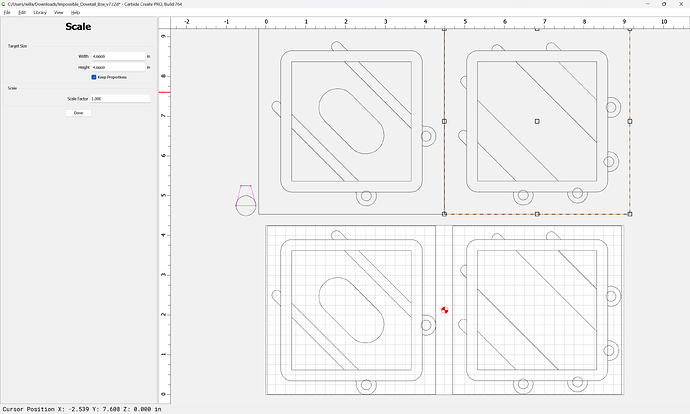

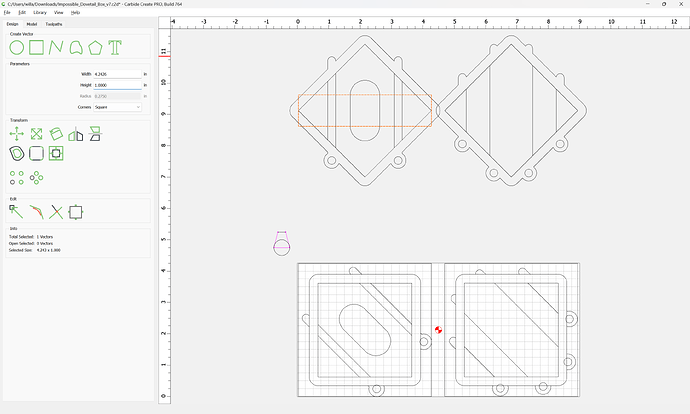

Increase the size of the surrounding geometry so that it projects beyond the other outlines:

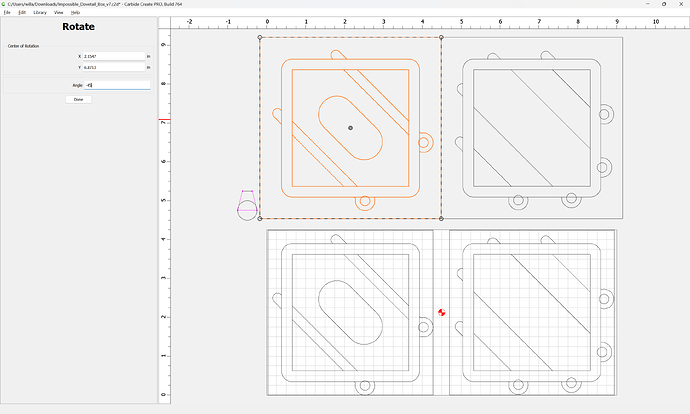

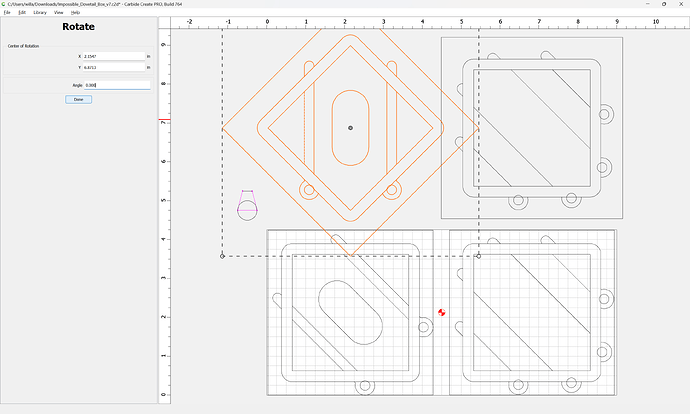

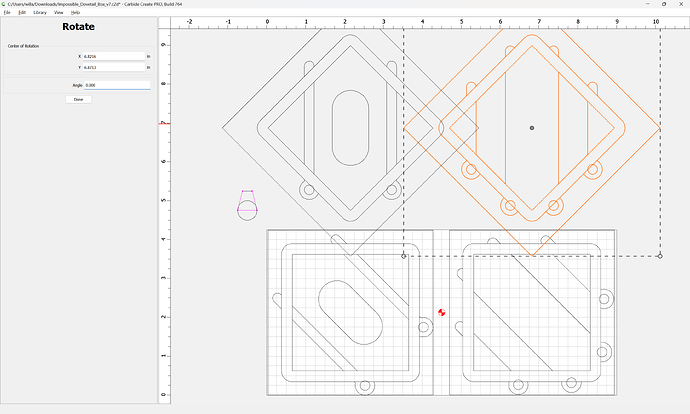

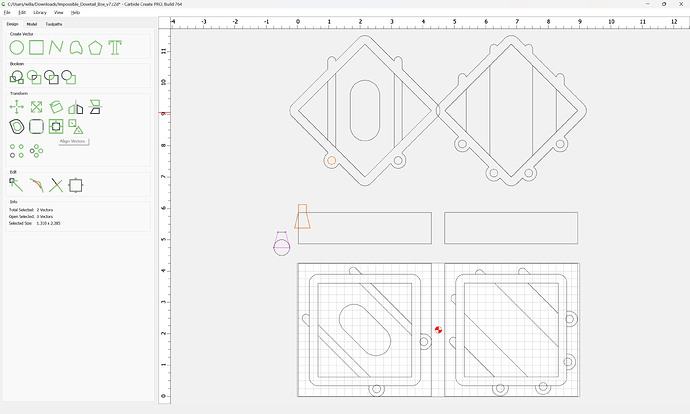

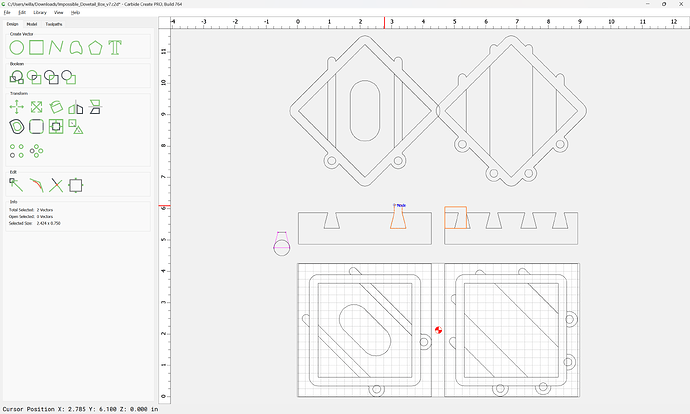

Rotate each -45 degrees:

Done

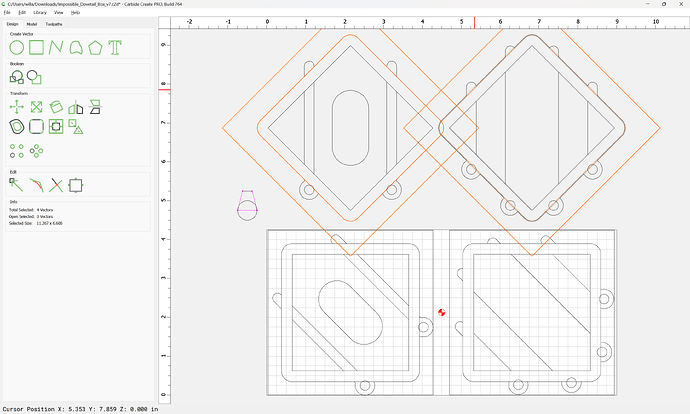

Remove the unneeded outlines:

Shift things up a bit to make room for the profiles:

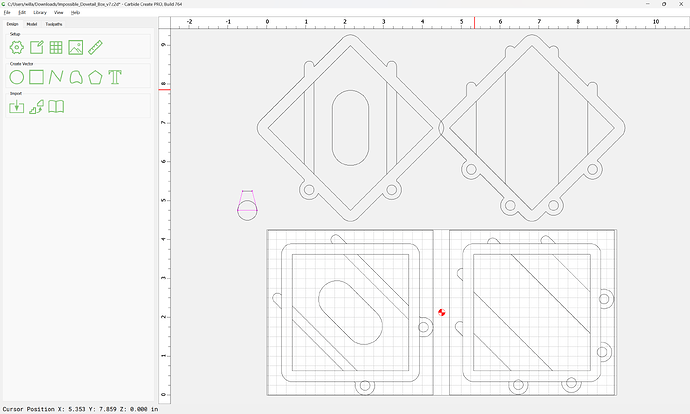

and draw in rectangles:

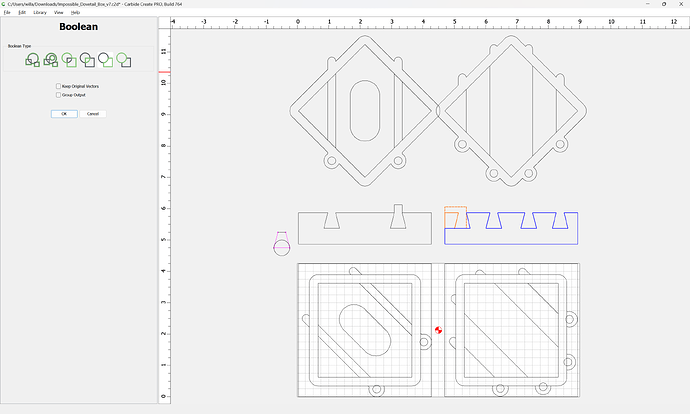

Align an outline of the dovetail tool with the profile:

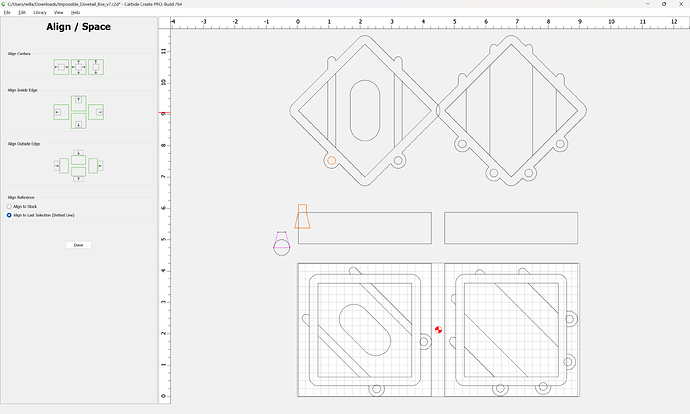

Select the feature which it will be matched with and use Align:

to move it into position.

Repeat for the others:

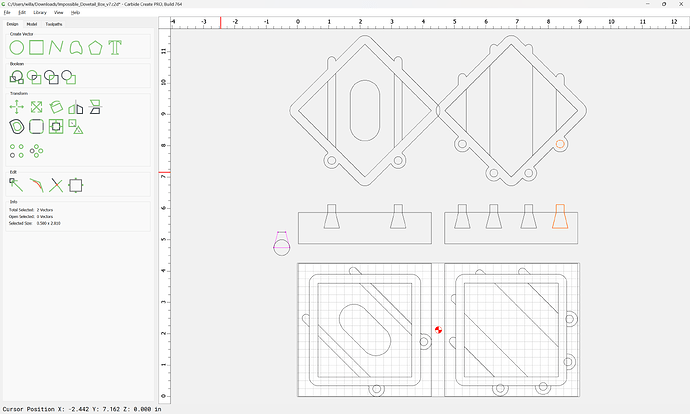

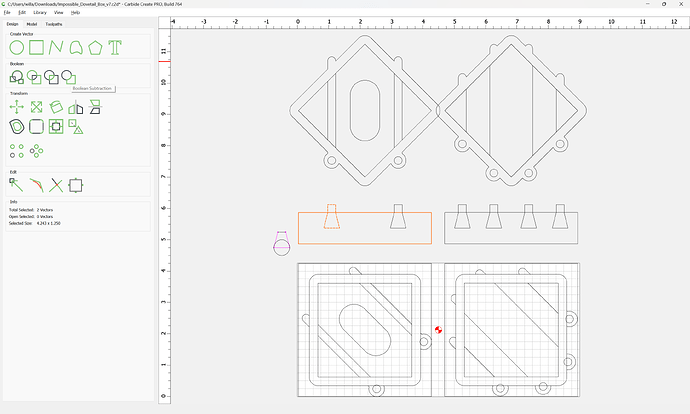

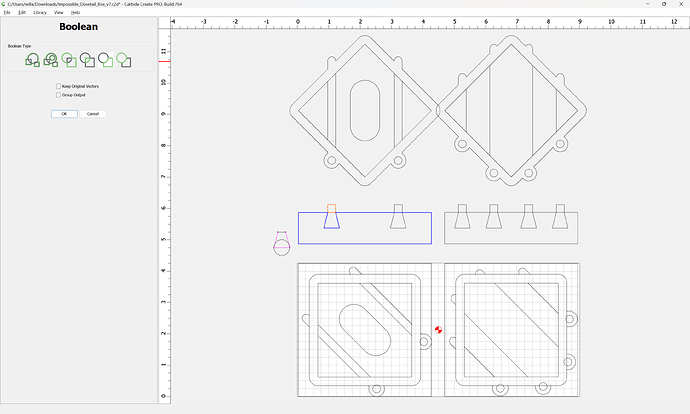

Boolean subtract each (or use Trim Vectors):

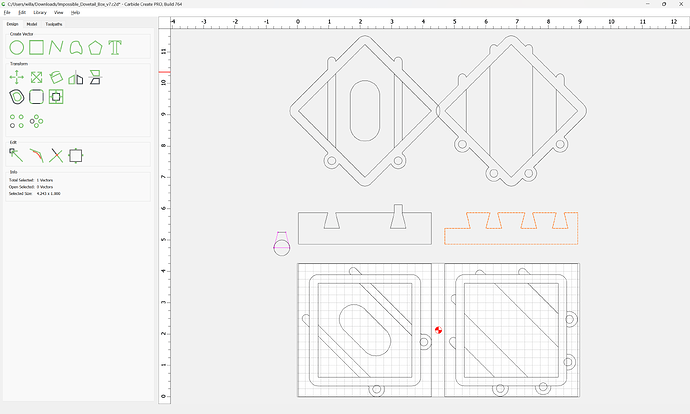

Draw in geometry to match the pockets which will be cut to either side of the dovetails on the lid:

and align it with the bottom of the dovetail cut:

Boolean subtract it as well:

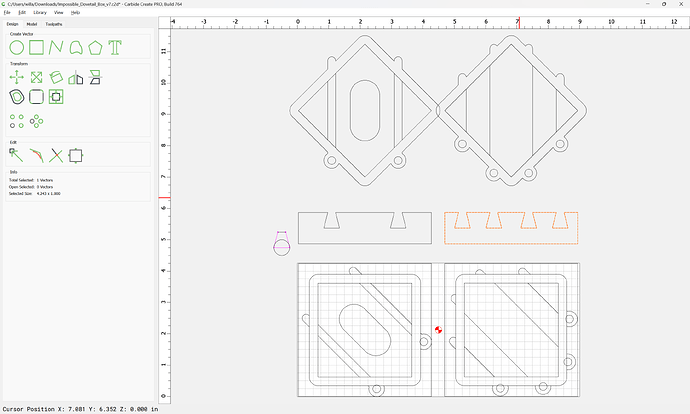

Repeat until one arrives at:

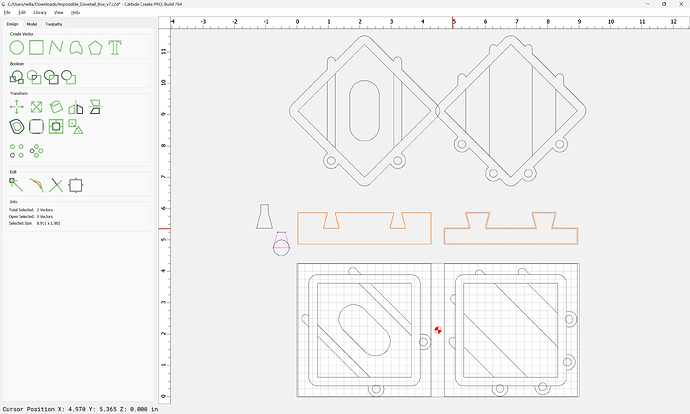

Duplicate the lid, rotate it 180 degrees and check the fit/match:

and apparently the dovetail toolpaths need to be shifted a bit…

WillAdams

February 3, 2024, 11:01pm

24

This much:

hang on while some adjustments are made…

WillAdams

February 4, 2024, 1:34am

25

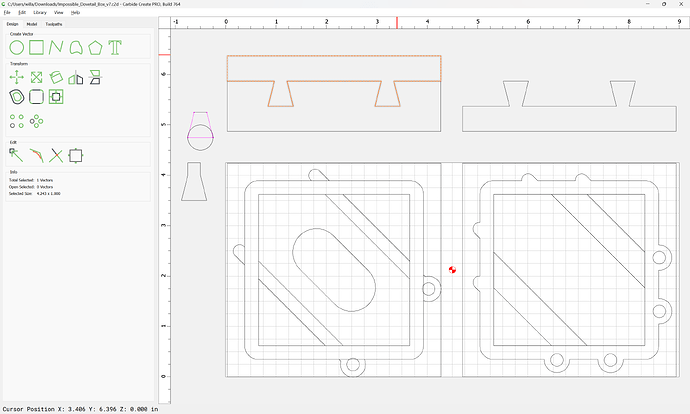

Eventually we arrive at:

which passes muster and is okay to go on with separating into two files (once we chamfer the corners)

1 Like

WillAdams

February 4, 2024, 2:47pm

26

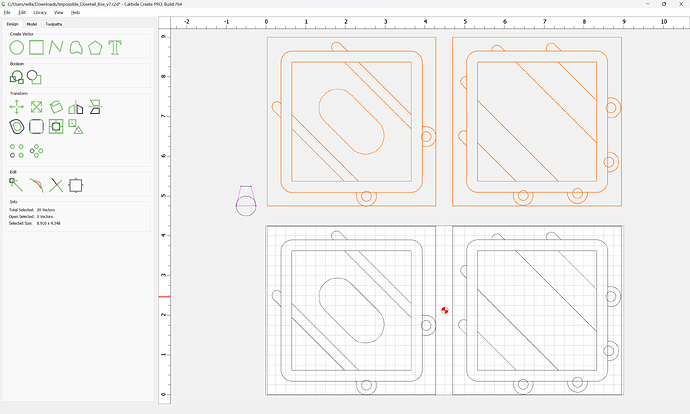

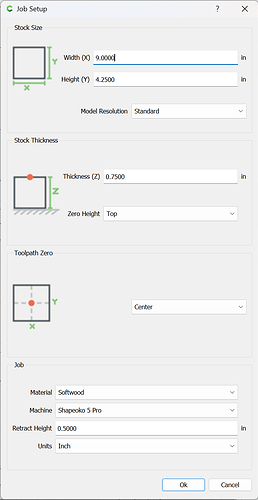

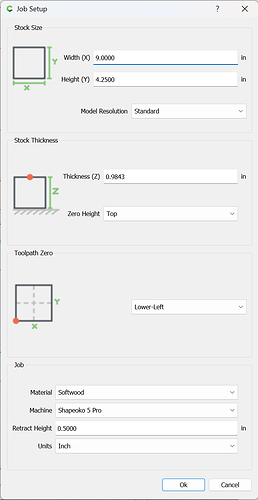

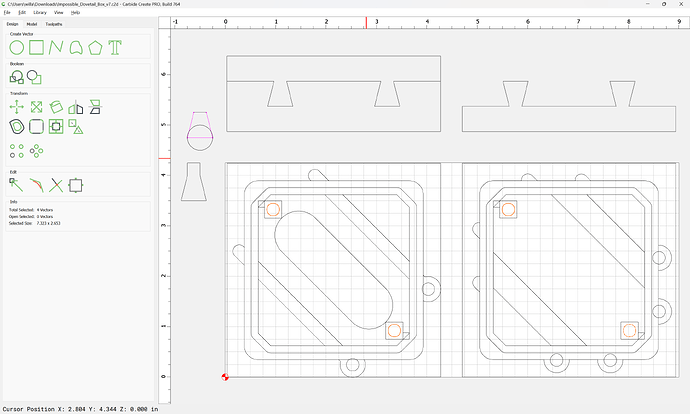

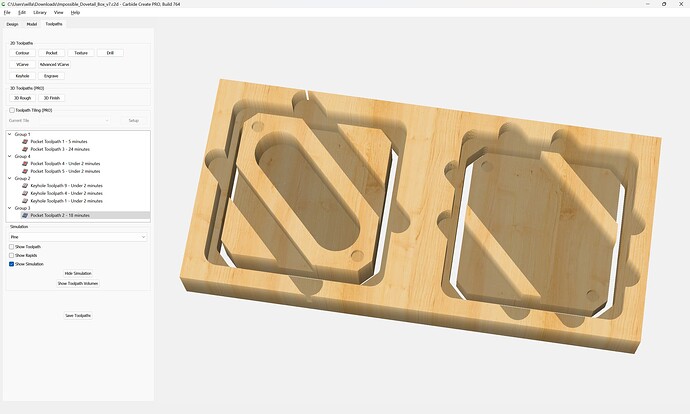

To keep this simple, we’ll do one piece of stock and centered as shown above:

First step is preparing the stock — the piece I have in mind is rough-cut, so there will be a bit of prep-work, probably a separate post.

WillAdams

February 8, 2024, 11:24pm

27

Or, maybe it’s easier to match the stock as clamped in place:

One other touch is pockets for magnets:

Hopefully final version:

Take 2

Impossible_Dovetail_Box_v7.c2d (132 KB)

Note on tooling — the last toolpath in the above uses a #102 , but this needs to be a long reach tool, in this case a Garr Tool Series 620MEDP#41030 1/8"x3x1"

https://www.garrtool.com/product-details/?EDP=41030

The dovetail tool used is apparently discontinued, but was still available on Amazon:

https://www.amazon.com/Freud-Dia-Dovetail-Shank-22-104/dp/B00002241Z

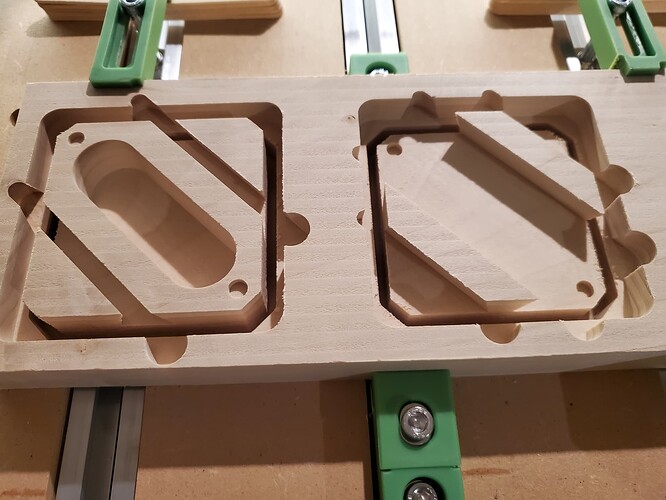

Note on workholding — belt and suspenders will be needed here — you’ll want an adhesive workholding system holding the parts in place, or you’ll need to add tabs, or you’ll have to do as I did, and halt the cut short of the bottom and cut the parts free by hand.

WillAdams

February 9, 2024, 1:19am

28

And success

Note that with an onion-skin, one can hold things up to a light (or use a lightbox) to determine where to cut:

except for a bit of post-processing and installing magnets and finishing:

A couple of minute’s work w/ a file and plane:

7 Likes

WillAdams

February 10, 2024, 2:47am

29

and a bit of sanding and gluing magnets and we have a product which just wants a finish (probably just oil and beeswax)

8 Likes

WillAdams

February 10, 2024, 1:08pm

30

Project post-mortem:

There was some tearout (as can be seen in the photos), and some uneven tool alignment — leave a roughing clearance for final passes — recommended tooling for final passes:

the dovetail tool — add additional passes w/ it using the keyhole tool so that it cuts the bottom of the entirety of the underside of the lid

a sharper tool for the sides — need to find a long-reach 1/8" downcut

Another possibility is just cutting it to final dimensions after putting in the magnets, cutting it to final dimensions/shape on my Jointmaker Pro:

A traditional way to make boxes is to make them all of a piece, and then cut them apart — this can be made easier by cutting a slot, and cutting through at the corners, but this results in losing the width of the slot (or more when a saw is used to finish) in height.

Couldn’t resist picking up a JointMaker Pro when they were recently on sale at Bridge City Tool Works:

so have to try it for cutting apart a box:

[20230803_2121241]

3 Likes

Zman

February 11, 2024, 11:54pm

32

Fir needles are the bane of my life. They love my dogs hair, my shoes,…

WillAdams

February 15, 2024, 2:56pm

33

The shade and wind break makes the bother worth it.

We have pretty decent mats inside/out which get most (and no pets unless my son is visiting w/ his dog) — I just sweep each time my wife leaves the house (we disagree on the topic of wearing shoes in the house).

I believe the 14 degree tool in this bundle:

https://www.rockler.com/4-piece-8mm-dovetail-router-bit-upgrade

would be a workable replacement for the above dovetail tool — wants an 8mm collet though (which I think is a good idea, and worth trying).

I believe it’s also available separately:

https://www.rockler.com/8mm-14deg-dovetail-bit

2 Likes