Hello everyone,

I’m making my first end grain cutting board in black walnut with inlay. I need to smooth the surface and did some tests with the mcFly Cutter. It works quite well but I quickly get traces of burns on the wood ![]()

I don’t have a drum sander and I’m not sure that running the endgrain through the planer is a good idea. Also, I don’t want to spend boring hours sanding with my little orbital sander ![]()

![]()

![]()

Have any of you ever done this sort of thing successfully and how? Maybe another bit than the mcFly on the CNC? A magic trick?

Thank you so much!

JL

Please provide metrics.

- speed of router, etc.

Here is my numbers and it’s working well without burning

Burns - you’re spending too much time in one spot, friction builds up, etc etc.

Fix is lower RPMs and higher feedrate. If the machine is bogging down, reduce DOC.

In MDF, I run 10K RPMs, and start at 100IPM. I usually use the feedrate override to between 150% to 200%. For hardwood I’d probably start at 75 IPM, then use the feedrate override to see how fast I could run it, then use that as the starting value from then on.

Burns are caused by the friction of the router bit. The larger the bit the more heat is generated. So most 1" or larger surfacing bits have to be run at higher IPM so the bit does not dwell in one spot too long. When the router makes turns it slows down and can leave burn marks in the corners. So to get higher IPM you need to reduce depth of cut so a trim router can handle the load of a big bit. Trim routers are not really designed to run bit bits. So when I run my surfacing bit which is 1" on MDF I only take 0.010" depth of cut partly because I do not want to take off much material on my spoilboard. Plus on end grain it is much more likely to heat up and burn than face grain. So increase the IPM and make shallow depth of cuts.

Luckily I have a Jet 16-32 Drum sander and it is really handy for removing epoxy and wood inlay. The planner is quite violent and can pull inlay right out of a project. Add on the end grain and a planner can cause a disaster. People do it all the time but you are likely to ruin your work with a planner.

So if this is a one time project it is not worth buying a drum sander. However if you are going to produce these on a regular basis it may be worth the investment. My drum sander is used all the time for a lot of projects.

Hi Martin,

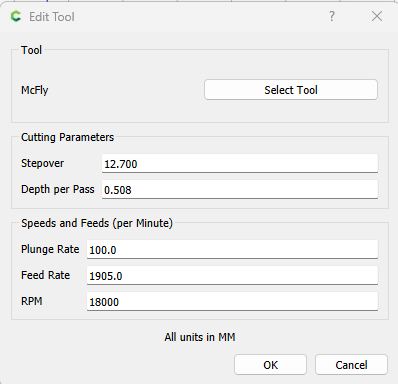

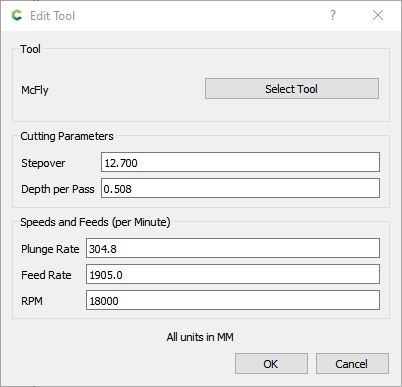

Here are the default mcFly parameters on my CNC…

The only difference is on the “pluge rate” value… Mine is 304.8mm and your is 100mm

I am not sure that it makes any difference…

What do you think?

JL

Hi Michael,

Thank you for your answer ! I will test an higher feed rate and a lower RPM…

JL

Hi Guy,

Thank you for your answer!

First, I will test a lower RPM and a higher feed rate… I expect several tries an error…

Regarding the drum sander, I have a question… I consider buying a very good orbital sander (maybe Festool or something like that) with the dust extractor…

When I look at the price of a brand new Jet 16-32, it is quite the same as a Festool orbital with the dust extractor.

Also, I want to develop some activity that involve sanding a good amount of flat surfaces (cutting boards, signs…)

This is something I have to think about…

Here is my question : as sanding is always required, should I first buy a drum sander or a good orbital sander? I can always sand details with my actual orbital sander…

JL

I’ve been doing woodshoppery for 15 years. My Festool hand sanders are wonderful in that the dust extraction is very efficient and vibration is low. Any handheld sander runs the risk of altering the flatness of your project surface but you can learn to make it work.

A large drum sander is wonderful for making things very flat very slowly and is best used as a finishing tool. NEVER use one without good dust collection as it produces very fine particles.

Which one to get first? It depends on what type of work you will be doing. Cutting boards, etc? Then the drum sander will prove very useful. More random projects? The random orbit sander will be more versatile. If you get both the problem solves itself.

Something else to check is that your inserts are actually sharp. I got a brand new fly cutter from Amazon a while back. One of the inserts was visibly dull on one of its edges and I was getting slight burning. Looked like a manufacturing error. I rotated the insert and the burning went away. Contacted the seller and they send me a new set of inserts.

Hi, the plunge rate is only how fast the Z go down. For sure it will not impact on burn rate.

It’s something else.

I have used a Festool Rotex 6" RO sander. It is a beast at removing material. However as @HaroldO mentioned a hand held RO cannot guarantee flatness. Depending on how you hold your RO it can dig in and cause less than perfect surfaces. That said most people when they pick up a cutting board cannot tell with their eye if it is flat or not. The drum sander is a great tool but takes up space and is expensive. I bought my Jet about 20 years ago and the price was much cheaper than now. I dont specifically remember the purchase but I can almost guarantee it was bought on sale. The drum sander can be slow so you have to take small bites to keep it from bogging or burning the surface as well. The drum sander gives you a flat uniform surface. I have grits from 60-220 but only use 150 grit. Most of what I put through the sander are semi finished projects. I am not trying to take down rough surfaces.

You definitely need an RO sander. My Dewalt 5" has worked flawlessly for years and is good at dust extraction on its own. If I put a shop vac on it it is almost perfect. I do a lot of woodworking and therefore a lot of sanding. I bought a 20V Dewalt RO sander and that is useless. I though having the freedom of no cord would be good but it is very slow and terrible at dust collection. If you put the vac on it you just lost the main feature of its portability.

The Festool has some unique features for the Rotex like its aggressive mode. That will take stock off like nothing I have ever used. You have to just hang on but if you hold too tightly it starts bucking like a bucking horse. The 6" pad removes more material than a 5" but at the price and having more tools like the drum sander the Rotex is not worth it for me. The other factor of a Festool Rotex is the price and the price of the sanding pads from Festool. They are very proud of their products. For a production shop the costs may be worth it but for a hobby shop as least for me not. The other advantage of the Festool sanders is the availability of different density of pads. They have multiple types of pads but again at a price. Most RO sanders have a single pad and no options for density. All RO sanders benefit from a sanding pad saver. It is a thin pad that attaches to the builtin pad and the paper attaches to the other side. This saves the velcro from becoming worn on your builtin pad and saves the expense of replacing it. I have went through 15-20 RO pads over the years.

Here is one example of the pad saver. A lot of vendors have this pad.

I would suggest you get one of these for any RO you buy.

So to sum up, a RO sander is a basic tool. The drum sander is a nice to have but not core to a woodworking shop. That is not to say that a drum sander is not a great tool if you can afford one and have the space.

I have a Ridgid 5" RO sander that the bearings are worn out. The Home Depot Ridgid tools have a lifetime warranty but would not honor the warranty. No reason given and they just returned it to me unfixed and denied the warranty. My Dewalt just keeps humming along and has never failed me. There are other brands that are good but Dewalt yellow is all over my shop. Plus at the price point of most RO sanders wearing one out is a badge of honor that you used it enough to wear it out.

Guy,

Thanks again for your documented answer. This will help me make the right choice for my current situation. I don’t have a very high budget but I can make financial efforts provided I make an intelligent and satisfactory choice. Quite a challenge…

That said, I have a few avenues to explore from those suggested to me before spending the money. If I’m successful without spending any money, I’ll come back with some details, if it helps anyone.

J.L.

I will note that I stopped using power sanders a while back.

I bought a Mirka hand sander, which connects to a vacuum:

and have tried very hard to set up all my projects, so that that suffices for sanding.

Hi Will,

Thank you for your answer. But hand sanding end grain is really difficult.

Correctly setting up the project is clearly a good starting point. More set up give less sanding.

JL

Hi all,

FYI, I applyed Martin Seguin recommandation : lower RPM and quite double Feed Rate and I got a very good result!

So, problem soved…

Thank you all for sharing your knowledge.

JL

I have owned a Performax 16-32 drum sander for years and it is one of my most used tools. There are so many times when it comes in handy for creating a smooth, even surface. It is not as effective as a surfacing bit at evening out boards that require it. However, once surfaced to a reasonable degree, the drum sander works marvels. It’s a great combination with a CNC router.

John

I bought a used Performax 16-32 about 18-20 years ago. I have used it sparingly due to the fact that the UPS guy tossed the box over my front gate and damaged the machine. Anyone that has one of these knows how heavy they are and how stupid that was.

I got it working but I have never really felt that the drum was perfectly parallel to the belt which is the whole point. I typically only use it on narrow stock since the difference would not be as pronounced.

Now that I have a CNC maybe I should revisit the idea of trying to calibrate or at least verify its flatness.

Hi Cullen,

The drum can be adjusted to run parallel to the base. I haven’t done it in a while but the manual describes how to do it.

John

Thanks that is assuming something important isn’t bent. But I will check it out.

The shaft of the motor that drives the belt is slightly bent so that motor bobs up and down as that belt rotates but that isn’t really a critical piece. The potentiometer is flaky as well so there are only certain speeds that work. I assume I could order a new one of those but it was never a super critical item either.

Is it truly burning - or - are you seeing the cutter patterning on the end grain ? I also appreciate the speeds/feeds provided by Mseguin - I will note this in case I have burning - but I have a drum sander and use that. There are people that have had success running end grain through planner - search youtube for those that do - bevel cutting the edge (I think) is how they prep the board for planning.