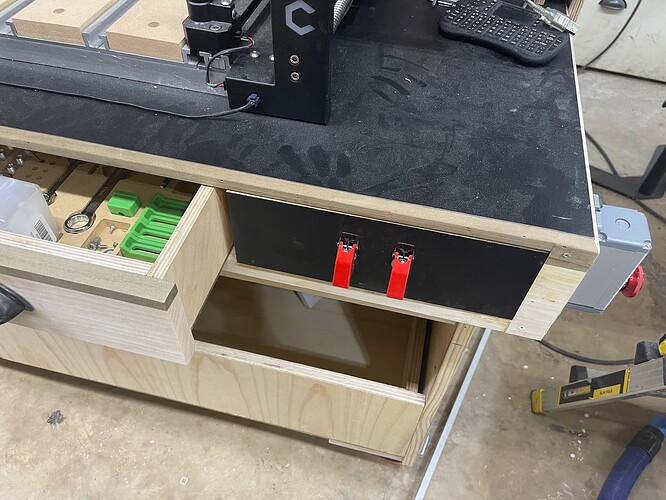

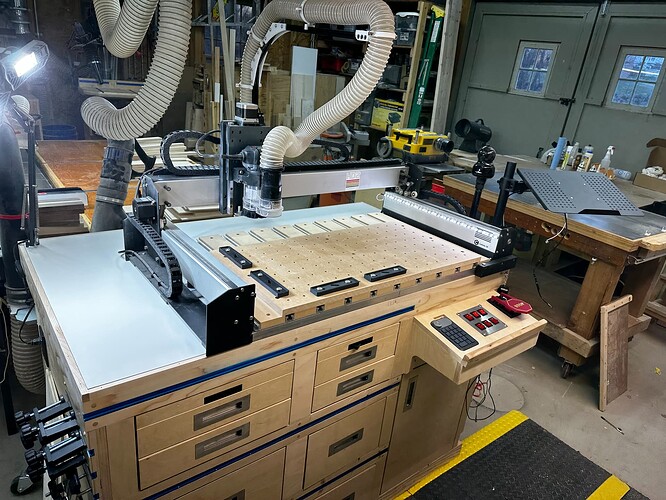

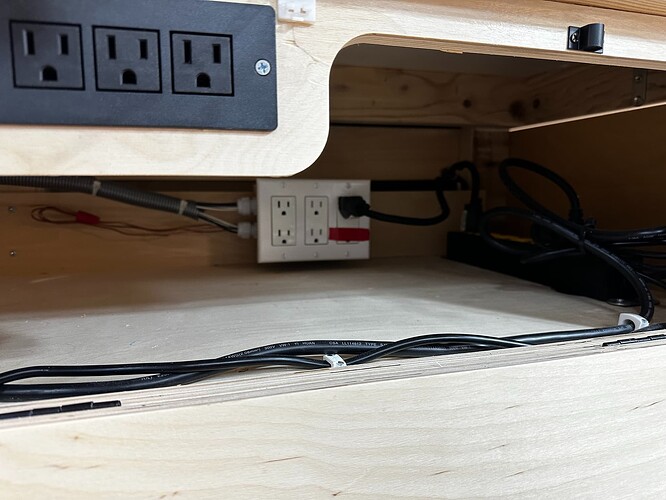

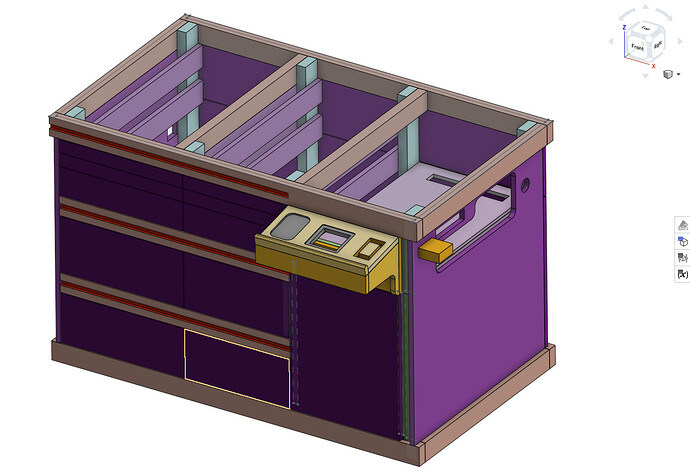

I built my workbench and have run electric and dust collection beneath it. Everything is coming together just great, but I’m a bit stumped about making a control panel and am looking for inspiration.

I need 4 switches and perhaps a paddle switch.

Looking into covered switches, lighted switches, rockers and toggles. So many options.

Wondering if there is a panel set that someone sells that is geared towards a workbench (110V, 20A heavy duty). Many options are 12V for boats and vehicles.

Also, if there isn’t someone who specializes in fantastic panels we can use for our CNCs, why not and who’s with me on designing a proper control panel for our workbenches?

These seem just fine - https://www.amazon.com/Nilight-90014E-Rocker-Toggle-Warranty/dp/B07QKFD7Z7/

I’m really into the aesthetics part of this process and I could easily fix these to my table and be done with it, but something is calling me to find or make something much better. There has to be a maker out there specializing in such a product.

Hope you are all having a wonderful day. Today is my first day with a functioning CNC machine, so life is definitely different now. Life is good.