Hey everyone! I’ve been sitting on this post for a while, but I’m pretty excited about it. I know there have been others that have done a rotary axis, and I have always wanted to try it. I finally realized that, with three kids (not counting the SO3), I have no free time. My hopes of DIYing a 4th axis aren’t going to happen. I went with an “off-the-shelf” version, and I couldn’t be happier with the outcome.

I wanted to share my experience with connecting a Vortex Rotary Axis from Sienci Labs to my trusty Shapeoko Pro. I really didn’t know what it would take to get it going, but I figured it was made for a grbl based machine/controller so it should work, right?

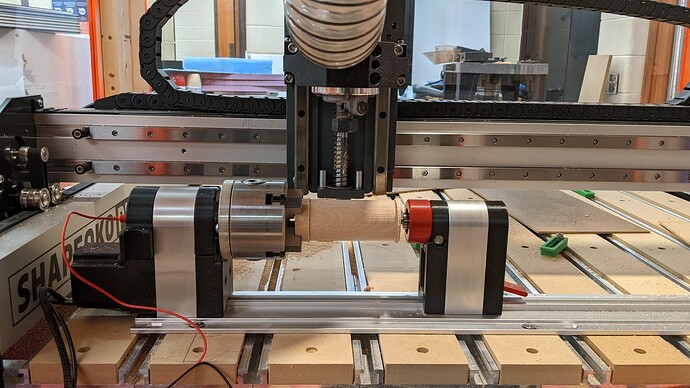

First, a look at the first attempt at a rotary carve:

After getting the Vortex, I was impressed by the simplicity of it all. It’s really just the chuck, tailstock, and a custom extrusion to mount it to. The part that really impressed me were the integrated, 3D printed parts that make homing and probing seamless…more on that later. I was also impressed with the online assembly and getting started documents from Sienci.

It’s really solid and fairly easy to remove and put back in place when going from Rotary to Y.

I fully expected some challenges with the main three being: wiring, aligning it to my X axis, and keeping the Y in place.

The vortex comes with a switch that allows switching from Y to A for rotary jobs, but it simply disconnects the Y motors and connects the rotary (A) motor to the controller. This should only be switched when power is off, by the way. I knew that would not be enough on the Shapeoko Pro (or 3 or 4 or probably HDM and 5) because of the belts. This just leaves the Y free to move. I thought about shorting the Y coils when the switch is flipped to A, but that holding resistance is too weak to do much. I next toyed with using multiple relays to connect the Y motors to a separate controller that would simply put the Y steppers into a hold state. I finally settled on just clamping the thing in place, guessing that I was overthinking the whole thing (I tend to do that sometimes)…more on this later.

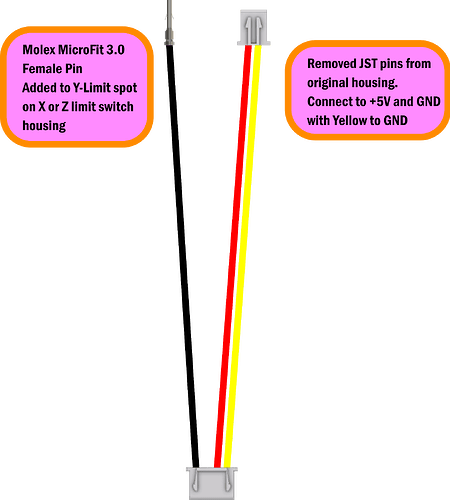

My next mission was to handle the wiring…ugh…the variety of connectors. Luckily, I teach electronics, so I had some connectors and tools on hand. After an Amazon and a DigiKey order I was able to make the necessary adapters.

After I got these adapters made, I thought I’d just mount the thing, clamp the Y and go. But, how do I mount the thing? Well, gSender has a built-in gcode generator for mounting the Vortex (They use ¼-20 threaded inserts). There’s a problem though, because I don’t have a Longmill…I have a beast of a machine called the Shapeoko Pro. Not to worry, I used their open source files to generate gcode for the mounting holes that would fit on the MDF slats on the Pro. I generated some counterbores and tapered bores to match the taper of the threaded inserts. I also set my Y-Zero in Fusion to be on the centerline between the two left holes. That way, I could decide where the Vortex fit the best, zero Y there, and hit the slats exactly as planned. gSender also generates gcode for hole pairs, but I’m comfortable with my Fusion workflow so I went with that.

Great…easy. Now I just have to clamp it and go! I tried every which way to clamp the Y-axis on the SOPro, and I could not find a consistent method that prevented the Y from moving. After way too long, I finally came up with little 3D printed linear rail clamps. They clamp on the Y-rails in front and back of each Y-plate. I made a split clamp design, so I don’t have to slide them on from the front and rear of the machine. That’d be obnoxious on an XXL. Here’s what those look like:

Once that problem was solved, I was ready to go.

The procedure is pretty easy:

- Home the Shapeoko normally.

- Use gSender to set “Y-alignment”…this basically ensures that your X-axis is centered on the Vortex. I chucked up (doesn’t sound right) an aluminum tube to do this because the Vortex chuck is too tall to run the probe routine on the chuck. I’ll probably write a macro to do this without the tube eventually.

- Once aligned, I installed and tightened the clamps (while the Y is still powered).

- Power down, flip switch, power up.

- Set rotary mode in gSender (this adjusts the steps/mm for rotation)

- Home machine again…it’s fun to see the Rotary axis home!

- Set X-zero, as normal, by eye.

- Set Z-zero using the built-in probe routine, probing the chuck. This sets Z-zero in the center of the stock which makes sense for rotary jobs.

- Run the job!

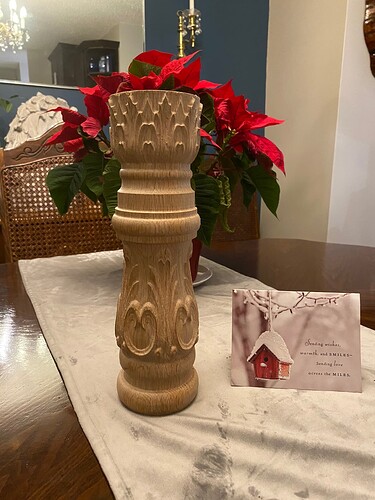

I downloaded a gnome stl by Body3D on Printables. I used V-carve Pro (v 9.5) and a custom post processor to generate the gCode. I used a flat ⅛” tool for the roughing, and a tapered ball (0.5mm tip) for the finish. I rarely do 3D reliefs, so I was impressed with the results.

Sorry for the long post! This was a fun project to get working, and it’s so cool when things just work! Not sure of my next rotary project, though a custom tap handle sounds like an obvious one.

Let me know if you have any questions. As always, I can share any STLs, files or post processors if you’re interested.

TLDR: Made my Shapeoko spin.