This post sounds exactly what the title implies. I’d love to know how all of you organize your cables for your machine(s).

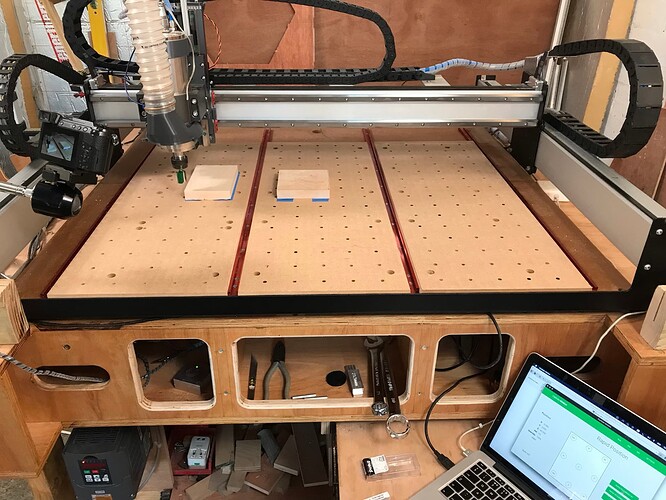

My shop is pretty well kept in terms of minimizing the chaos with proper dust collection, cable management, organization of tools, supplies, etc.

However, when it comes to the CNC, It’s been a permanent temporary solution for FAR TOO long!

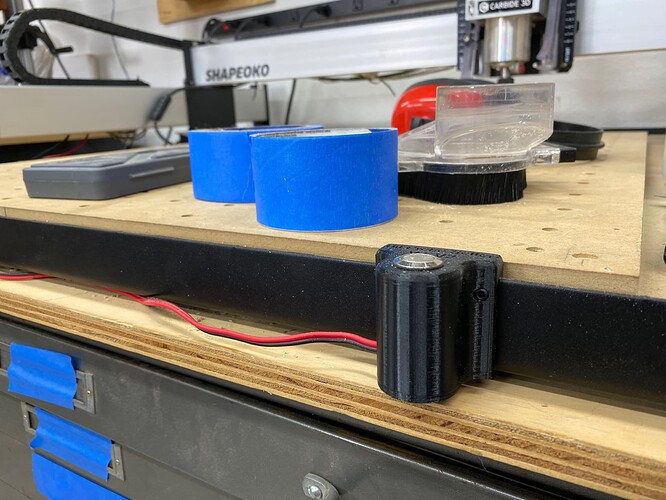

Also, to add insult to injury, I recently installed a bit setter and a feed hold button as well as a E-stop button to kill power to everything in the event of a “oh sh*t” moment.

All that being said, I’d love to see everyones photos of their set ups to see what worked, what didn’t work, etc.

After roughing in all of the new components I added; needless to say, it’s been bugging me for 2 weeks and I want to tackle it but I’d like to see some photos for ideas/inspiration.

I’d like to move my box that contains the vacuum, router power, and control box for the cnc to the front of my set up. However, the biggest thing I’m trying to figure out is the makita router power cable ( I’d like it in that box but I’d also like it so the cable is obviously able to move freely along the entire size of the cutting area. Idk if suspending the cable makes most sense or an extension cord with ample “play” for it to move freely, etc. would work.

I’ve seen enclosures posts that people have posted about that topic but not so much about the “internals” of how they got there.

So, let’s see how everyone has done it! I think this would be a nice post for all of us “advanced and nOObs, alike” to get ideas.

I’ll go first. (again, posting this so I can nip this in the butt and get it clean!!!