I have created a couple 2.5D tool paths and I know I’m over looking a step that’s causing this issue. When I go to cut the machine starts cutting about a 1/4 above my material! What step am I messing up??? New and I’m racking my brain??

Thank you

are you setting your z axis datum?

I believe so? Are you refuring to setting zero on my machine to my material manually with the jog feature. Or am I missing a z setting in the software? I did set my x y & z on the jog after I loaded the job.

Is the material thickness correctly set in your CAM software?

I believe so. It’s happens two times in two diff jobs now. I end up walking away for a bit because I don’t want to get aggravated, I’m not giving up. My nomad is awesome I just feel like an infant learning to crawl!!

if you are setting the xy and z with the jog correctly then as Rich said it’s probably an issue with your cam programing, what software are you using? If it’s carbide create I’m sure that it will be an easy one for the guys to solve for you, just give Carbide3D a call.

It’s easiest for us to troubleshoot if you describe at each step:

- what you did

- what you expected to happen

- what actually happened

I was working with meshcam, but I think I found my issue I did not enter the z in the define stock in meshcam. I did in my first define stock. It I did not in the to bring the z to 0 as top of my material section. I will retry tomorrow and know for sure. Also where are you guys finding your 2.5 and 3D files?

I design most of my parts.

Except for my latest project (Power Hack Saw, which provides 2D drawings, that I use to draw 3D models)

Some resources for this here: http://www.shapeoko.com/wiki/index.php/Online_resources#Project_Design_Sharing_Sites

c.f.,

I’m w/ Rich in usually drawing things myself:

- http://www.shapeoko.com/projects/project.php?id=1

- http://www.shapeoko.com/projects/project.php?id=154

- http://lumberjocks.com/projects/75378

The last was done w/ hand tools and along w/ a Bridgeport which wouldn’t fit into my basement, was the impetus for getting a machine.

Thank you WillAdams, I am driving my self crazy with this. It’s a lot harder than I though. But it’s an awesome machine (Namad883) and I’m definitely not giving up, well as long and my newb questions will be answered!! Thank you again to you and all who help!!

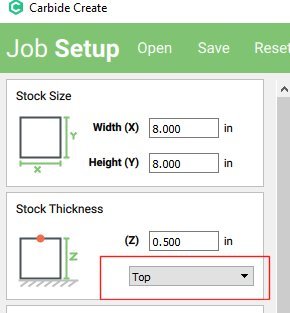

I just did this 2 days ago. When setting up the stock in Carbide Create (CC), I forgot to set the stock thickness from the bottom and set my zero from the top of the stock. If your Z zero is going to be the top of the stock you need to indicate that in CC setup.

My job was running a half inch above my job because I had that setting at Bottom instead of Top.

I also design my parts (in solidworks)

what project is that Rich? I need a power hacksaw

If you are interested, you can type Power Hack Saw in YouTube from user myfordboy

I’m about 90% complete. It’s an old but solid and proven design. I really like the set it and forget it design with auto off feature

Today was welding day (I decided to forgo the Silver Solder)

There is a similar input int meshcan and i believe i was missing it. Thank you for the heads up. Im going to get a couple hours ont the nomad later tonight, i will check that setting…

Thanks for the info Rich!

@BrianK

If you have a file you need help setting up, post it and I can help with the settings.

You can also download .mcf (MeshCAM) and .c2d (Carbide Create) working files from these projects and take a look at the settings I used.