Hi, I am having an issue similar to this where I have inconsistent Z values after the bitsetter runs.

Workflow:

I set the XYZ using the BitZero V2 and confirm that it zero’s out to the current XY plus 6mm.

Then I am asked to load a new tool (it remains the same tool I used to probe the XYZ), it goes over and measures the offset and when the job starts it will either cut air around 1/8" or so above the piece, or it will cut too deeply by a similar amount. This is an intermittent and random occurrence.

I can reinitialize and probe XYZ and run again and it will be fine. I have had it happen where the EM plunged all the way through the workpiece and into the spoilboard.

Has anybody seen anything like this?

Thanks,

Bill

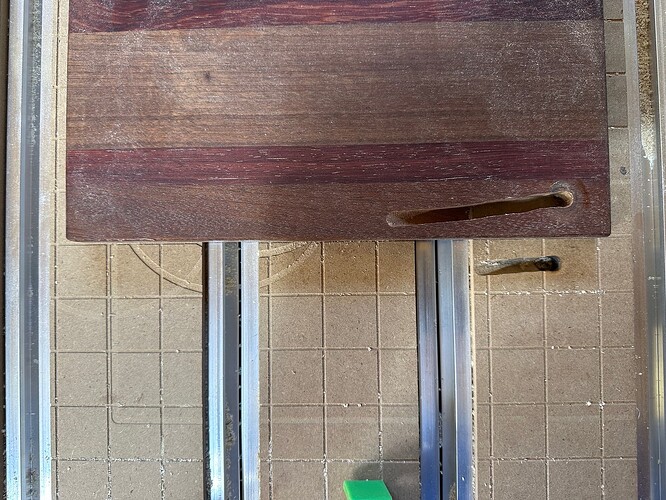

Plunged through the stock and spoilboard

Started at the right, came to the left too deeply and pushed the workpiece. That cut should have been 0.02" but was more like 0.125" instead