WillAdams

(William Adams (Carbide 3D))

2

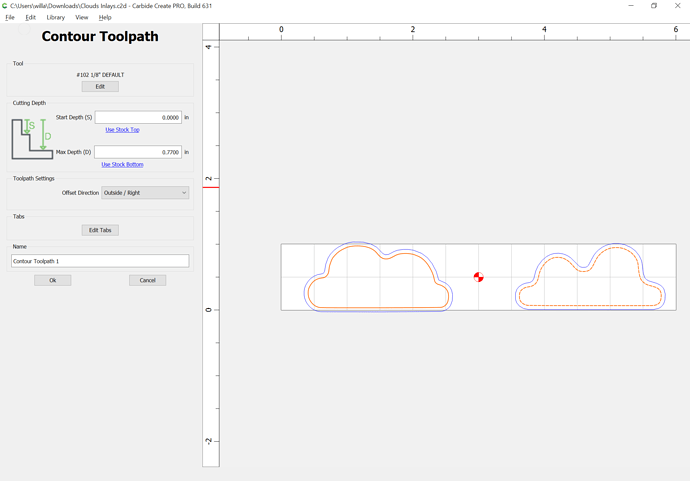

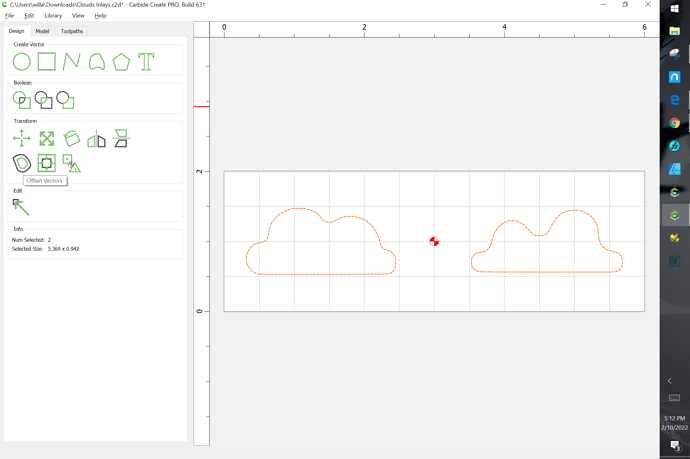

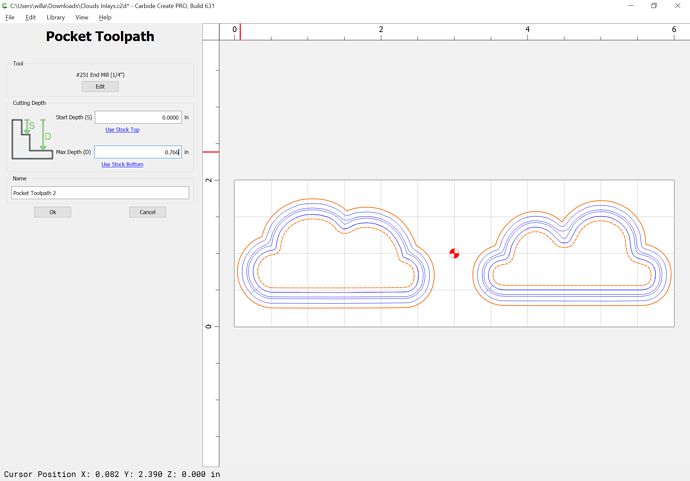

Geometry matches up, so files ought to be good.

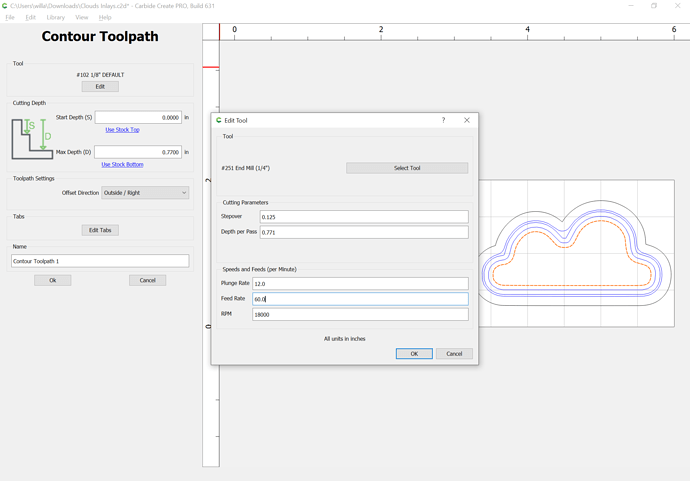

On concern is you’re cutting a slot over 3/4" inch deep w/ a #102:

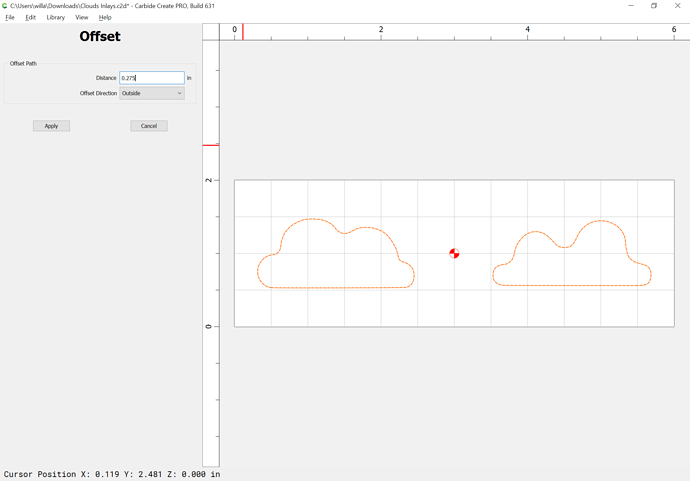

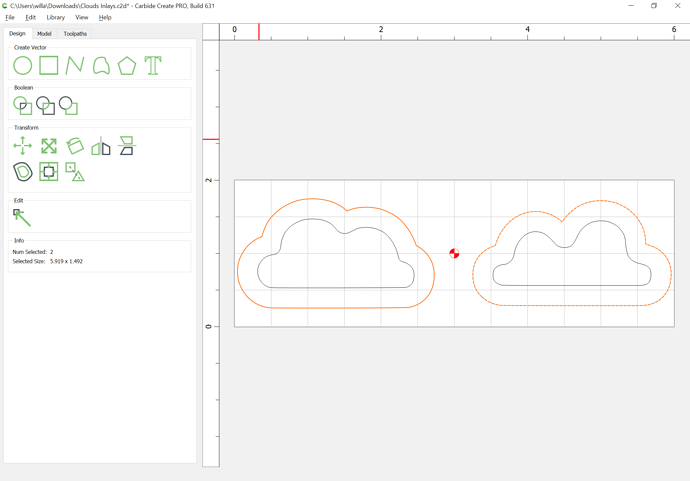

It would be better to use a more rigid tool and to add geometry and cut as a pocket down to tab depth or the penultimate pass:

A further improvement would be to leave a roughing clearance and make the last a finishing pass.

And if you haven’t, yes, you should calibrate:

That said, why not do a V inlay?

1 Like