More of a fun curiosity than anything - is there any kind of internal counter, either in hardware/ mb or in carbide motion or anything that keeps track of operating hours?

No, there isn’t a feature for that.

I try to remember to write the begin and end times on 3x5 cards which I use to record each job, and the approximate run time — every so often I tally things up, and every hundred hours or so, do a PMI.

I saw a thread recently, don’t know if it was here or FB. Someone was getting an hour meter to incorporate on the unit.

Ok, then may I offer this feature suggestion: a job log in carbide motion?

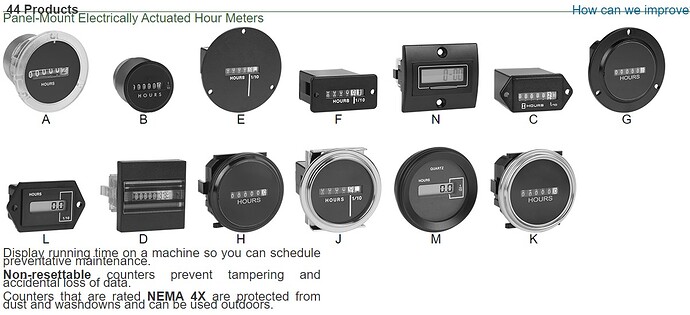

The Shapeoko controller is not that smart. It does its intended purpose but it is limited in scope to being a machine controller. There is no battery on the controller to keep an internal clock running like on a laptop/desktop computer. As Michael Zemanek suggested get yourself an hour meter and put it inline with the power for the Shapeoko. It will record number of hours on but not actually cutting a job. If you want to record the number of hours your router runs then you could hook up the hour meter to the router and get a more accurate measure of time the router runs. If you want both total hours on and total hours the router runs then get two hour meters.

Who knew but there is such a thing as a vibration activated hour meter for the purpose of tracking how long equipment has been run ($15). I’m not sure if the router has enough vibration for it (these things are intended to be put on diesel generators and such) but at least one guy in the comments said he was using it on his CNC machine and it worked. I’d consider putting it on my shop vac instead, which runs pretty much in sync with the CNC.

https://www.amazon.com/AIMILAR-Wireless-Vibration-Hour-Meter/dp/B081MY6ZWV

McMaster Carr has hour meter counters I think may be what you are looking for.

Although this would be a nice addition to Carbide3D Machines.

The more detailed info and the reviews say:

- internal non-replaceable battery. Expect two years or so.

- 0.1 hour resolution is six minutes. If you run for five minutes and stop, it will throw that time away!

I think you can attach a time collection device to it with a low pressure vacuum so you can collect the lost time into a container and recycle it later.

Oooh, and if I hook that container up to my Delorean, and get the speed up to 88 miles per hour, what happens then? ![]()

If you’ve set the zero on your flux capacitor using the BitZero 3 and have the appropriate feedrate (for stainless steel), you’ll end up exactly where you are at exactly the right time.

Got a little off topic don’t you think?

Yes. Thanks for pointing that out.

I was waiting to see the outcome of the discussion to see if there were other options out there.

I go back to my suggestion that a Job Log in carbide motion would be a handy feature for a variety of reasons, only one of them being that you could add up your cut times and know what your total hours are. Could also have the actual cutting time logged vs estimated. And if you could add notes they might be helpful as reminders on future cuts. I could probably come up with a bunch more benefits. All it would take is generating a log file when cutting is complete, and then putting those logs into rows on a table.

Seems like Will does this manually for his own purposes, might not be a bad idea to make this easier for users since carbide products are all about ease of use.

This is on the todo list for CM in the medium to near-ish future. We need to get some new plumbing in there to have a way to hold the data and log it.

That’s good news! Looking forward to it. Thanks Rob

By plumbing, are you referring to the machine or software?

Plumbing within the software.

Putting in a sink, or a toilet? ![]()

It just struck me odd to use that term.