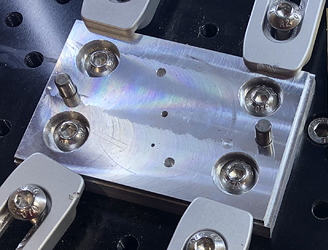

Here is a close-up of the pin-jig. Both top and bottom are surfaced to guarentee that the surfaces are parallel to each other and normal (perpendicular) to the Z-axis of the Nomad. Notice the machined perimeter with parallel edges. This perimeter is used with an edge finder to locate zero in X and Y (zero in Y aligns with the pins). Zero is found by taking measurements with the edge-finder at both edges, then subtracting the difference and dividing by 2 and adding this to the current machine offset from zero, i.e.

X_zero = (X_right - X_left)/2 + X_offset

Y_zero = (Y_top - Y_bottom)/2 + Y_offset

This perimeter is also used to align the jig X-Y axes with the Nomad X-Y axes. For example, to align the X-axis, use an edge-finder at X_min and X_max and make sure that the Y value is identical, otherwise adjust the jig position. The same is performed for the Y-axis.

This alignment setup generally takes 30 minutes. The holes for the bolts are larger than necessary to allow for small translations in X and Y during alignment. The holes on the top are tapped and enable securing parts from a center mounted mandrel or bolt.