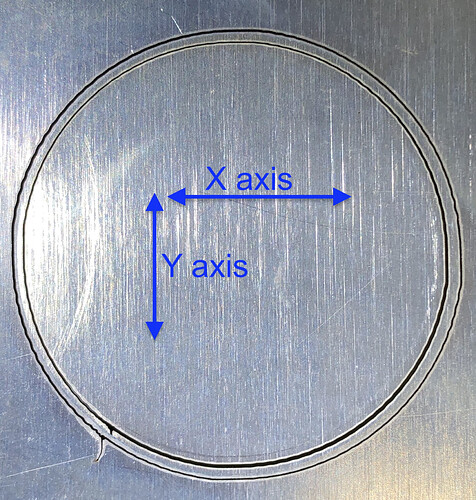

Was that drawn in Lightburn? I know DXFs get weird sometimes, but I see a lot of nodes. I wonder if a “better” circle might help with the motion control?

As you stated, the DXF definitely does not show any flats.

All circles are broken into line segments when sending to DSPs. If I import our DXF parts drawn from Fusion, there would be no change when it sends it over to the DSP.

So given the line segment nature, have you checked for a circle tolerance setting in light burn? It’s still seems weird that it would only apply on the orthogonal axis, but it might be combining with some other rounding behavior.

Yes, that has been previously mentioned. Changing the arc tolerance values from 5µM to 100µM didn’t change the cut quality.

Still waiting on UPS to show up with the belts.

Just to silence the crowd, maybe you could rotate the circle 45degrees as this would show that it is the machine, not the design

Ok, missed that. So based on that and your step testing it’s probably not exceeding machine resolution (too detailed/too many steps, in some segments you end up missing detail due to comms issue or rounding). Still feels mechanical, though it would be nice to have a compensation in software.

I’m actually hoping it’s the machine, which may sound weird! (please don’t be the linear carriages)

I forget, did you ever drop to 1/8 microstepping?

Yes  I can say it isn’t very fun taking the rack enclosure in and out. Getting too good at it, sadly…

I can say it isn’t very fun taking the rack enclosure in and out. Getting too good at it, sadly…

Here is a comparison of the stock pulley and belt vs the new pulley and Gates belt:

The original belt feels like a wet noodle in comparison!

Nice! How many teeth in the pulley?

24 teeth was the minimum available so that’s what we got.

So, 22.5um per pulse?

It’s gonna be fast!

11.25µM. Only a loss of 5µM ‘resolution’.

The pulley and belt are installed on the X axis (not doing Y yet) and feels better, but we shall see here in a little bit…

Edit: I was even able to easily reuse the stock Carbide3D belt tensioners. Actually seemed way easier with the thicker GT3 belt than the stock belt.

…

8 microstep?

No, 1/32. Changing from 1/4 to 1/64 didn’t do anything other than audible noise levels, so we left it at 1/32.

Just completed the first test with the upgraded X axis (Y stock). Honestly, I can’t tell if there is an improvement or not (maybe?) Feel like I’m trying to split hairs (or photons) here.

The little wiggle lines are really disappointing and I’m sure are attributed to all the line segment (nodes) that makes up the circle.

Forgot to add, we will try rotating the circle tomorrow as suggested and see if the flat spots move accordingly to figure out potential software issues.

Looks the same

If you cut an n-gon maybe starting from something like an octagon up to something that approximates a circle, are the cut lines still going to be wavy?

If I recall you shared some video but maybe not pictures of some straight cuts like squares and rectangles. How was the cut quality on those geometries?