As another counterpoint to add to your counterpoint…more power may not always be better for every job. Diode lasers typically have a smaller point than CO2 and are usually better at things like picture engraving if you desire detail over speed. And I agree that a diode on a larger machine opens up possibilities.

NEVER Run a non-industrial machine Lights out!!!

Update your xtool and it will support Lightburn.

This is for the D1 which is a diode laser. Their Co2 machine does not, and will not per them, support LightBurn.

Hey Cody,

That is pretty interesting, how does a 40W CO2 laser compare to a 33W diode laser? I don’t know much about CO2 lasers, (who am I kidding, I don’t know anything about lasers period, that is the reason for this post).

If I was willing to spend about a thousand dollars, where would that put me in a CO2 laser. Is a 40W CO2 laser powerful?

That size is very limiting, 8" x 12". That is one of the reasons i was considering an add-on to my XXL Pro, then I could use about 30" square (give or take a little)

What is the price point of your 100W CO2 laser?

Price point for a good 75ish watt Chinese machine is $7500 or so. I’d suggest omtech or aeon Mira lines.

You can get any of the k40 machines and gently upgrade them into a very capable, very useful machine for well under $1000. 40 watt will engrave whatever (non-metal) and cut up to .125" well.

I keep seeing adverts for diode lasers cutting 10mm wood and I don’t believe it for one sec. Maybe balsa, but come on…

My advice, get a Jtech for your Shapeoko. Unless you NEED a fast laser for production, use the tools you have available. Diodes are great for very detailed engravings, great contrast, but slow. They don’t cut well so don’t even try. I love my Jtech, it does great work, and the support is top notch.

I also have an Ortur Laser Master pro 2 as others have stated in the forum. I actually got mine long before I got my Shapeoko Pro XXL. I’d recommend it for an entry level laser, it’s helped me get quite a few projects done and sold in order to help fund my Shapeoko. I currently have both in my small shop, i still need to work out building (or buying) an enclosure to exhaust everything out.

I have a 10w (double laser) diode laser and can cut 1/4 inch in 2 passes… not super quickly, but doable, and does a nice job. I have no issue believing the 20w versions can cut more.

Think what you like. It’s your health. But don’t take my word for it:

Of course it can also be harmful to your eyes and possible radiation exposure.

Well I just ordered a JTech 24W quad diode and rotary setup to run with my HDM. I’ll make a thread as I integrate it.

Since you didn’t grasp the gist of what I said, you have left the impression that I said something different than what I really said.

Okay, sorry if I miss understood .

So I’m trying to get my setup ready for a powerful laser (which is in my near future, I can’t help it, this thread made me do it!), I followed @Able’s example and got an inline duct fan for smoke extraction

One end will go out the garage window, easy.

I already have an enclosure built around my SO Pro XXL, and when building it I happened to install a 100mm vent in the upper right corner (in the spirit of "the air that get sucked out of the enclosure by my dust collection should come from somewhere)

I have two options now

- route some length of 100mm hose through this vent and attach it close to the laser module, in the spirit of dust collection, so that it sucks air very close to where the laser will work. Probably the most efficient for smoke management, but it will require 3D-printing an adapter, supports for the hose, etc…

- just plug the 100mm hose on the vent itself, and continuously extract air out of the whole enclosure. Muuuuch simpler. Small desktop laser cutters do this (i.e. the air gets extracted from the enclosure), but I wonder if it would work well in an enclosure of a significantly larger volume like this one. Also, I wonder if over time my whole Shapeoko will smell like burnt wood despite the air extraction.

Thoughts anyone ?

On a separate note, I went to the big box store to buy stuff to make a cheapo metal bed for my future laser cutting jobs. Honeycomb beds look great but none is large enough for the work area I want (XXL Pro work area, more or less), and they would be extremely expensive.

So I got a large sheet of thin metal grid, and a number of L beams (which both happen to be exactly the width of the XXL Pro work area, yay)

I’ll paint the beams black, and add a black sheet metal backing.

We’ll see how it goes

- That would be the square surface area of a 100mm round vs. the square {front surface opening} area of ???. It would be better to mimic the dust boot on your router. Smoke collection isn’t about how you route the hoses.

- With all that hardware, are you planning on cutting all the way through some material? That must be some real powerful laser.

Not sure I get you there. The enclosure front door (not shown in pic) is relatively air tight so once closed it ends up being a large cube with a 100mm hole extracting air

Yes, my current 3w Jtech is perfect for engraving but I’d like to go to something able to cut e.g. 1/8" plywood. I’m really curious on what the C3D-approved laser will turn out to be, but as this thread and others highlighted there are now 10, 20, and now 33W diode lasers out there too

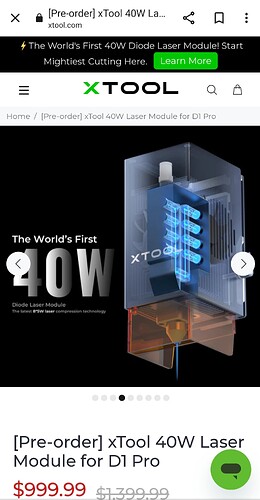

And now there is a 40W Iaser (pre-order). So this leads me to more questions. This new model that xTool is producing, it says is 8- 5W lasers in sequence.

I’m presuming that these diodes need to be placed VERY precisely otherwise the beam won’t have pinpoint accuracy. How do we keep them from getting knocked out of whack? If one diode starts to burn out or fail, can I just replace that one diode, do I need to replace all the diodes, or do I need to replace the entire unit?

So they have 6 - 5W lasers, and they are coming out with 8 - 5W lasers. Soooo, I’m guessing they won’t stop there, what is to prevent them from 10 in sequence, or 12 in sequence, or 20 in sequence…(20 - 5W lasers in sequence). Would that truly be a 100W laser? Who knows.

On the topic of your smoke ejection Julien, I like that airflow that you are working on!

For me, I’m seriously considering a free-standing unit. I know I won’t have the working capacity of using my XXL-Pro, but I’m not certain I need that at this time. Maybe in the future I may need that work space, and I can cross that bridge when I come to it. Also, I was wondering if I bought a free-standing unit, and then needed the larger work space, maybe I can get the mounting bracket and move the laser head to my Shapeoko at that time?

Anyway, again, I appreciate all the feedback and thoughts on this subject.

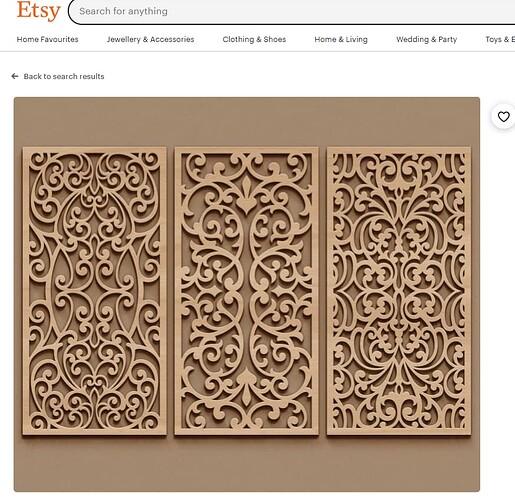

This is what I was talking about…

One thing is for sure, that niche (hobby diode lasers) is moving fast. I couldn’t justify spending north of $4000 for a glowforge or similar, but something in the $500-$1000 ballpark that would provide a somewhat equivalent cutting capacity (I don’t really care about speed that much) is a different story. Of course I’m comparing apples and oranges, the integration into a box and the associated ecosystem have value, I just don’t need those.

Let us know when you pull that trigger ![]()

So, I’m curious. You have a machine eminently capable of cutting detailed shapes in 1/8” plywood, a Shapeoko XXL Pro. Quickly cut I might add.

Other than coolness factor, what is the benefit of using a laser? The burned edge aesthetic? I know I’m missing something, please enlighten me

I guess I don’t have to prove how much I love my Shapeoko ![]()

BUT, this usecase:

If I cut a (very) large panel with relatively thin material, I can get away with “hiding” the radius of a small endmill, or I might even resort to v-carving. But when it comes to cutting through thicker material than e.g. the max length of cut of a 1/16 or even 1/32th endmill, and still get sharp inside corners…it’s difficult.

The charred look will be covered with paint in those cases.

but if I’m being honest, mostly:

and the joy of setting up my machine to try something new.

Well, it is a bit difficult to hold a 1/8" piece of wood down to the spoilboard, but not too difficult to warrant waiting for the laser to get through burning through.