I am expermenting carvinb on PVC and carved some letters 2.35 inches high and they came out with a web, or petetion in the middle, like both sides were carved but not enough width to finish the job, I was using a 60 degree Vee. I later carved letters 1.25 inches hight still using the 60 deg. vee and they came out perfect. I will experiment, but I see two solutions. 1. try to carve the 2.35 letters with a 90 deg vee or as somenone suggested us a ballnose bit to carve out the center of the letters and then then finish with the 60 deg vee. Any thoughts? The 60 deg is a Jenny downcut, does a super job with PVC, I change the speed and also the feed rate.

Please post the file and some pictures. I am not quite understanding the problem.

It’s hard to tell since you didn’t enclose either a picture OR the design file, but it sounds like either you programmed a No-Offset Contour, OR (more likely) you programmed a shallow VCarve with no clearing bit.

Post your design file.

PVC just does this. I’ve had the best results cutting the V first, then the clearing mill.

Single flute / o-flute clearing bit. And in this case, conventional helps.

Slow RPM, Fast feedrate!!

I did not touch the offset, but I don’t know about a cleaning bit. Because I am a newbe and expermenting with PVC carving it makes things all the harder. The 1.25 high letters carved perfectly with the 60 deg jenny downcut,

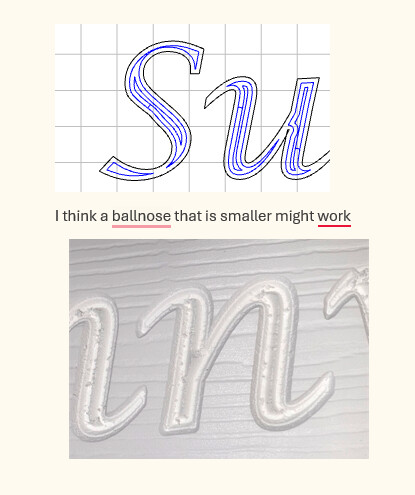

The larger letters 2.35 high and of course wider. looks like the bit carved both sides of the letter and left the center. I don’t know how clear it is in the pictures I took. I went back tonight and re-ran it 1/16 deeper and with a 90 deg vee, it cleaned it up a bit, but still there is material in the center. I just got some new ballnose bits and wondering what they will do. I can’t use them in V carve, it won’t let me use them just Vee tools, but I did try, but did not run the ballnose in the pocket, the drawing shows me it carves part of the letter, but only the wide parts, I need to try a smaller ballnose I think, It is late and I gave up for tonight.

It seems I would agree with mhotchin. Using the wider V bit will remove more material for a given DOC. Either use rest machining or add another tool path to remove the excess.

For a work-around for these sorts of difficulties see:

That said, V carving is optimal if suited to your project/material.

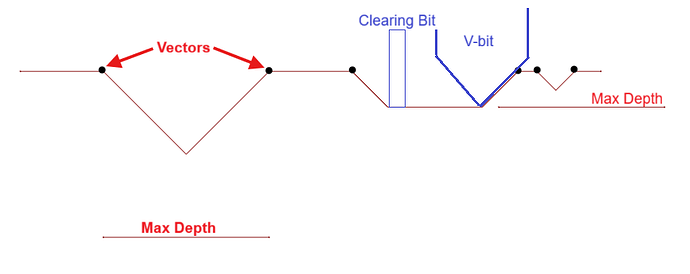

V-carve with only the V bit will try to cut deep enough to touch both sides of the pocket.

If the bit is wider than the widest spot in your letters, then set the Max Depth the same as the stock thickness, or even greater.

V-carve with a clearing bit (end mill) and a Max Depth less than what is needed to fully contact both curves will profile all the curves at that depth, then use the clearing bit to clear out the centers. In the areas where it’s too narrow to reach that depth, it will follow the curves on both sides and adjust the depth stay in those curves. If the area is big enough to need clearing, but too small to fit the clearing bit, it will clear with the V-bit using the stepover set for that tool. It won’t be flat, but it will remove more material in between the curves.

Thank you for your help and advice. I will work on it.

francis

I absolutely get it, thanks for opening my eyes to see what was happening. As a newbe, it is the simple answer that wins out. When first carving you develop fix mind sets of the way things are then as you advance and try new things you realize those simple things just don’t work. It is much like life itself, it flows along smoothly until it does not and you wonder what happened. I thought the only way to carve was with a vee bit as restricted in Carbide Create then realize their can be other ways, often better to accmplish your objective. I again thank all that have contributed to my learning, so much appreciated, francis