Thanks, I’ll look into single flute endmills, though I doubt I could use the same speeds and feeds as a Shapeoko with a 1.5kW spindle on my Nomad.

On a slightly related note: should I go for the 1/8 inch single flute or the 1/4 inch?

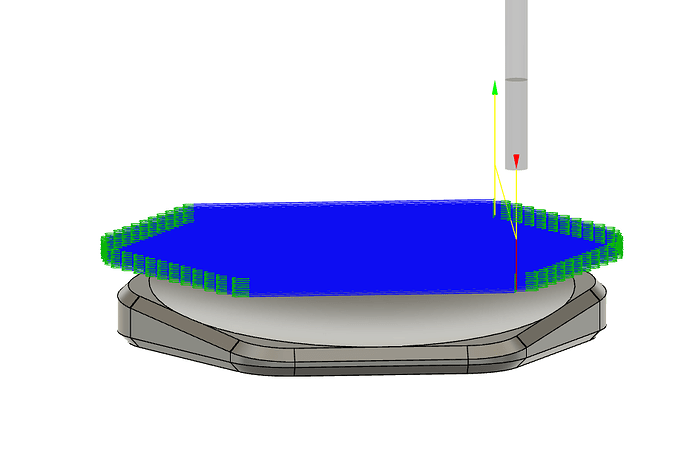

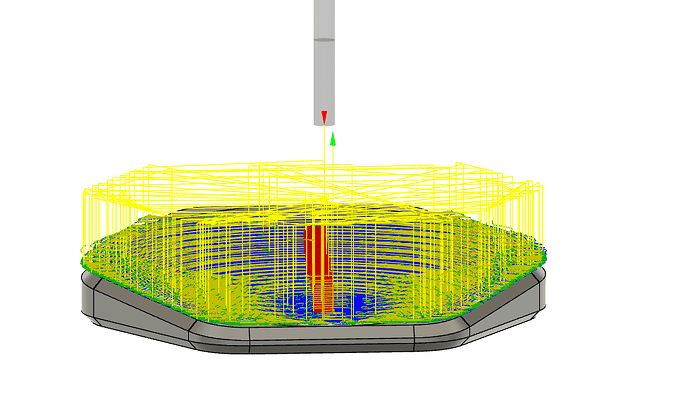

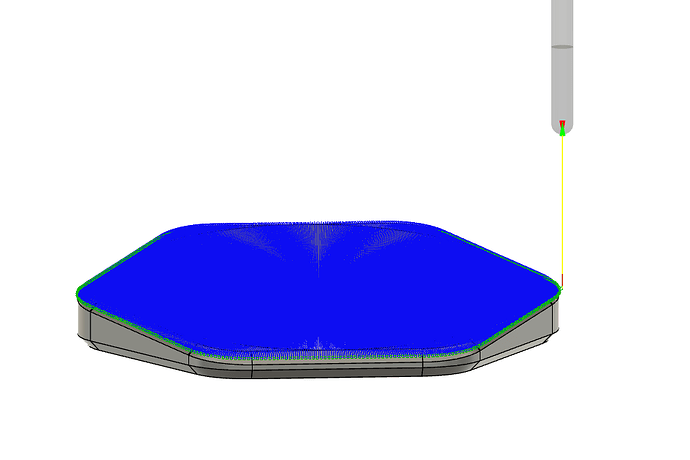

Oh man, a 0.170mm stepdown with a 0.2mm WOC and a really low feedrate? I mean, that’ll do it, but my laptop is currently having the time of its life calculating the 3D adaptive with those settings… For context, this is what I’m milling…

The feeds and speeds are pretty conservative — you should be able to adjust for efficiency’s sake w/ a bit of experimentation.

![]()

51 hours of machining… 54 megabytes of g-code for this one step. Are you absolutely sure?? 0.o

@Berend i would also recommend checking out the material monday videos.

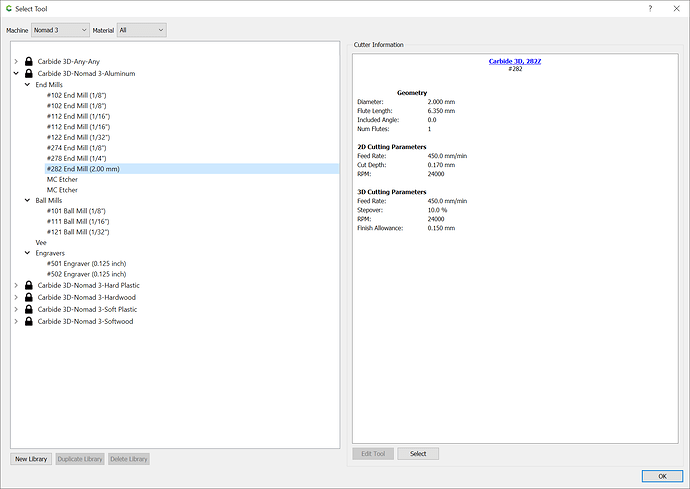

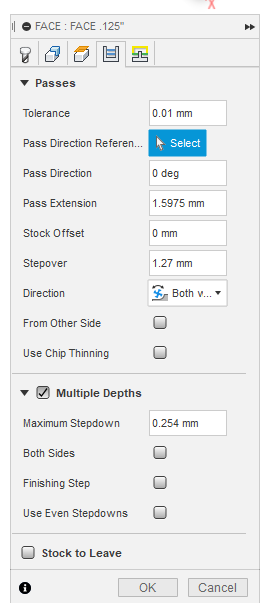

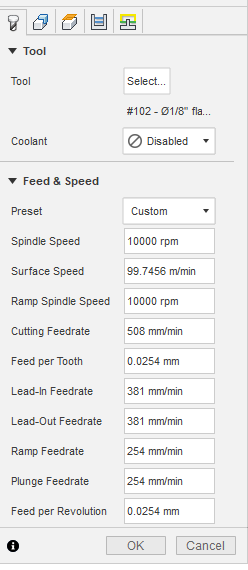

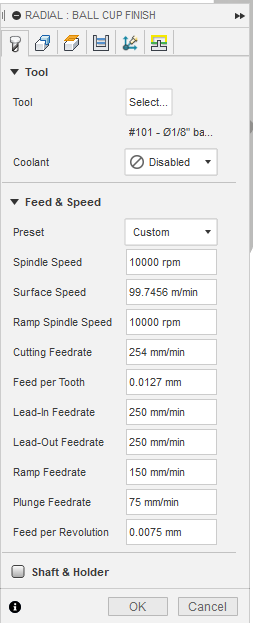

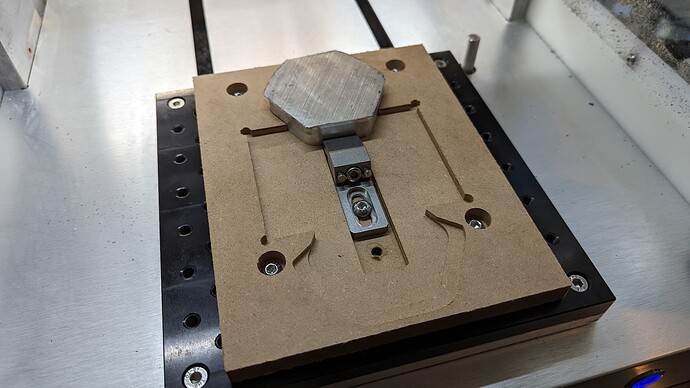

but if you want some photo & fusion evidence as to how well they work, here’s my f & s for a 1/8" 2 flute tool facing op. (i guess technically a 1/4" shank 1/8" 2 flute facing, now that im looking at the picture of my Nomad in action)

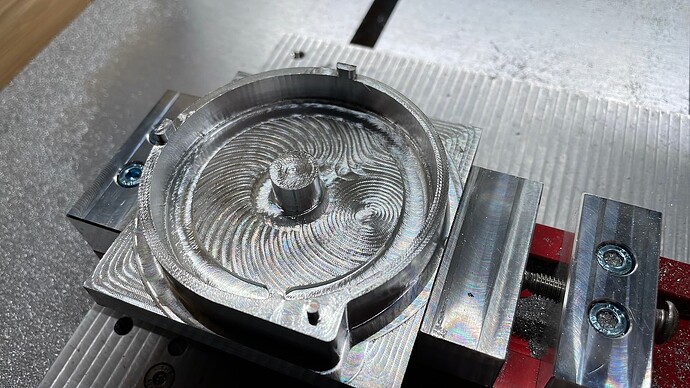

the resulting surface finish of those speeds

machining time: ~1hr

(the ugly top section was done with a 1/4" recipe i came up with did not work well)

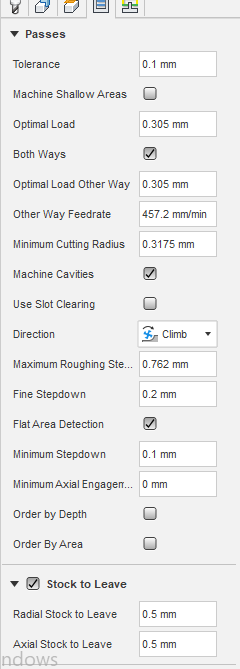

adaptive clearing using the same speeds, but the below cutting parameters

total estimated machining time: ~3hrs

and the resulting surface finish

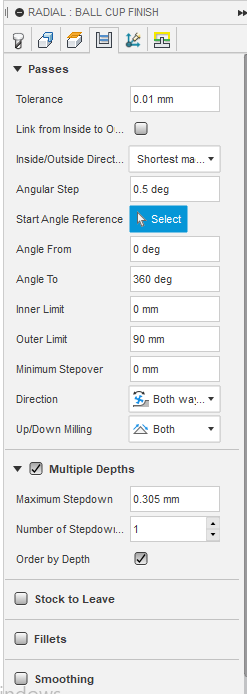

this is a recipe for 1/8" (1/8" shank too) ball endmill finishing pass

total estimated machining time: ~3hrs

aaaaand once again resulting surface finish (pre cleaning chips off)

after a clean in the sink

this maker coin/worry stone is approx 2" in diameter, and 1/2" thick, and was machined from a hexagonal piece of 6061 stock of that same diameter but just under 5/8" thick (hopefully that gives you an idea of the material that was removed.)

for reference, this is the piece of stock that i started with for the second operation.

Thank you! Is that on the nomad 3 or the original 883? Asking because you seem to be sticking to 10000 rpm.

its the Nomad 3, but the MM videos were based on the older Nomad iirc. you can scale these up from my understanding, to better utilize the RPM the Nomad 3 can deliver.

Yeah, they haven’t really updated the MM videos for the newer Nomad unfortunately. Would be interesting to see how the added rigidity of the Nomad 3 affects things as well. How’s the noise/vibrations at those feeds & speeds?

Whoa, I can’t imagine a 1/8”bit with a depth of cut twice its diameter into aluminum or even hardwood for that matter. I’ve been told I cut too conservative, but I usually go half the diameter doc.

Well yes, but with a tiny width of cut, around 0.12mm. Still, too much apparently.

its not quiet thats for sure but the machine doesnt sound unhappy. i would recommend earplugs/in ear headphones if its in your office (mine is) if you plan on running it all day.

This thread here

Thoughts on how to get past the z repeatability limits - #15 by Robthatguy

I listed some of my feeds and speeds. Just some extra info for you to take a look at. Alot of people use different feeds and speeds styles so you may end up with 3 or 4 different suggestions.

This image and video here was cut at 3690 adaptive .15mm doc 1.27 optimal load ( pretty agressive for the nomad) with toned down feeds for a finish. I was worried about a working part more so then surface finish.

Its important with the nomad to do a rough, finish and a spring pass. Small machines like this have alot of deflection to fight with.

how did you do the embedded video?

Post your video to imgur then copy paste the link here.

ah i was hoping i was missing a way of just embedding it. i usually open my google photos tab, and copy/past images.

You nailed it! Low DOC and wide(ish) stepover is absolutely the way to go on this machine. Only thing I did differently was use a 5mm 3-flute endmill at 20000 rpm with 2500mm/min feedrate. Machine was still sort of happy at 200% override, so 0.15mm DOC 1.25mm WOC 4800-ish mm/min. I think the extra rigidity of the thicker tool helps when flat milling like this. Machining time was about 20% higher than with a deeper DOC/low WOC strategy (I tried a whole bunch this afternoon, can’t remember the exact values, think it was 2.5mm DOC, 0.2mm WOC around 1500mm/min) but the machine was clearly a LOT happier. And so are my neighbors, presumably.

Here’s the initial results. Vertical walls have been finished with stepped 0.1mm DOC multi-pass 2D contours.

Also, turns out I was very much milling 7075 instead of 6061. That explains some of it as well.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.